Trolley conductor energy storage type construction elevator

A technology for construction elevators and trolley lines, applied in elevators, sustainable buildings, elevators in buildings, etc., can solve the problems of cumbersome installation process, broken cores, unsafe motor brakes, etc., to improve production efficiency and performance. , the effect of reducing safety risks and reducing installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

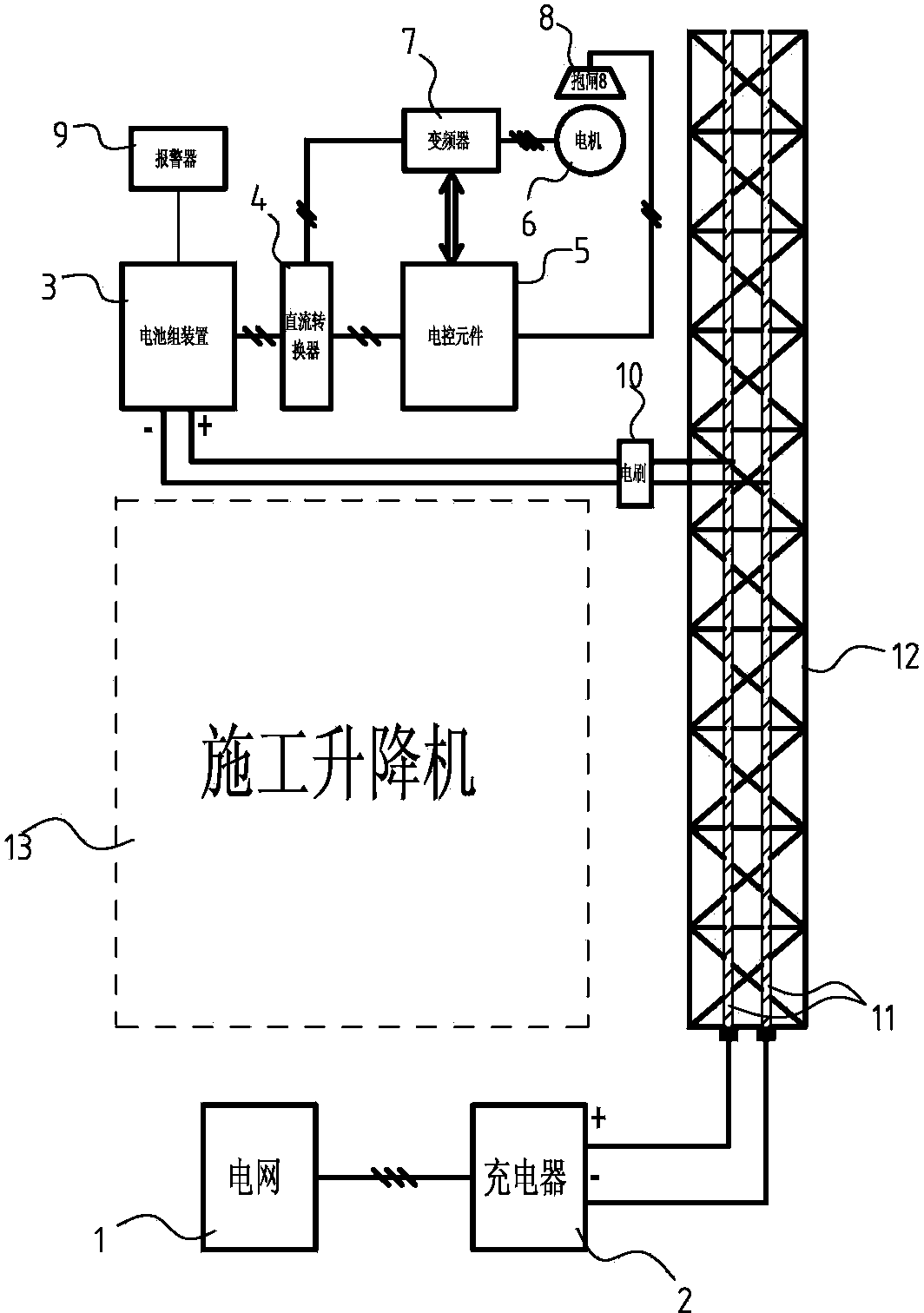

[0020] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0021] Such as figure 1 As shown, a trolley line energy storage type construction hoist includes a power grid 1 for connecting power generation and power consumption facilities, a charger 2 electrically connected to the power grid 1, and a sliding contact electrically connected to the charger 2 Line 11, the trolley line 11 is installed and fixed on the standard section 12, and the brush 10 electrically connected with the trolley line 11, the brush 10 is installed and fixed on the cage, and the brush 10 is electrically connected Connected, the battery pack device 3 for storing electric energy is electrically connected with the battery pack device 3, and the DC converter 4 for converting the DC voltage into a variable DC voltage, and the DC converter 4 converts the voltage into a suitable voltage It is electrically connected with the electric control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com