Tray truck with auxiliary supporting wheel device

A pallet truck and supporting wheel technology, applied in the direction of lifting devices, etc., can solve the problems of user efficiency loss, large turning radius, and insufficient mobile flexibility, and achieve the effects of reducing labor intensity, easy operation, and improving use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

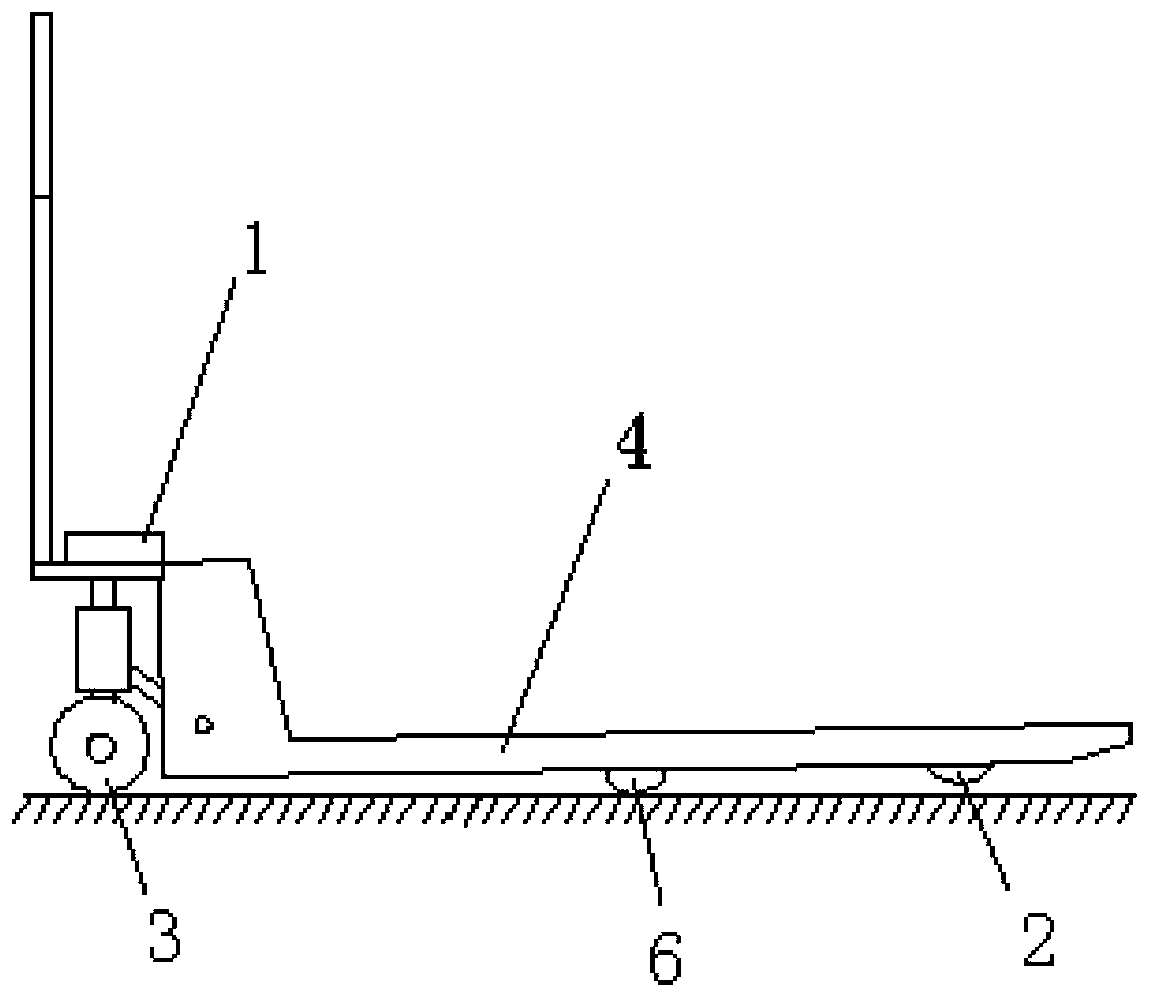

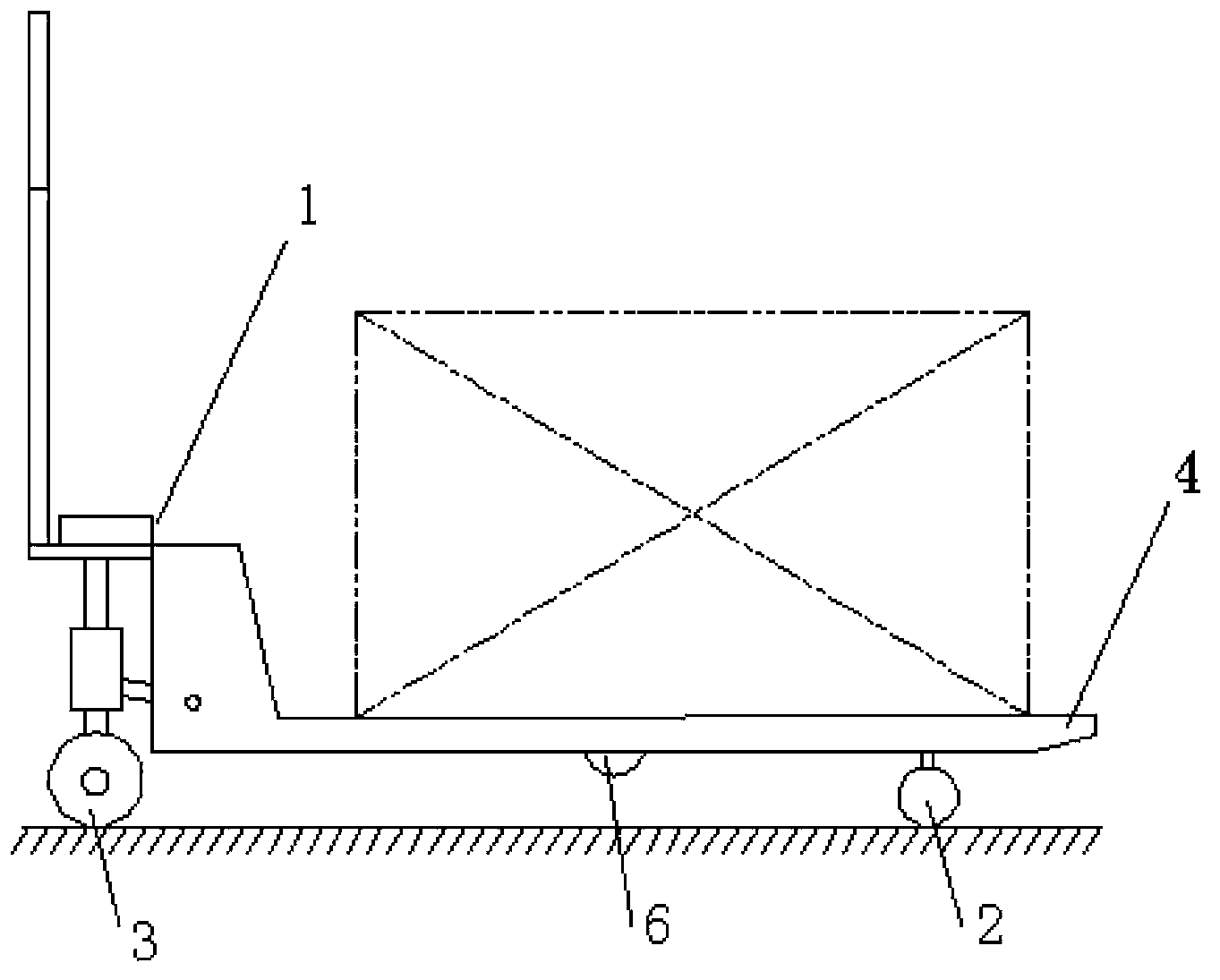

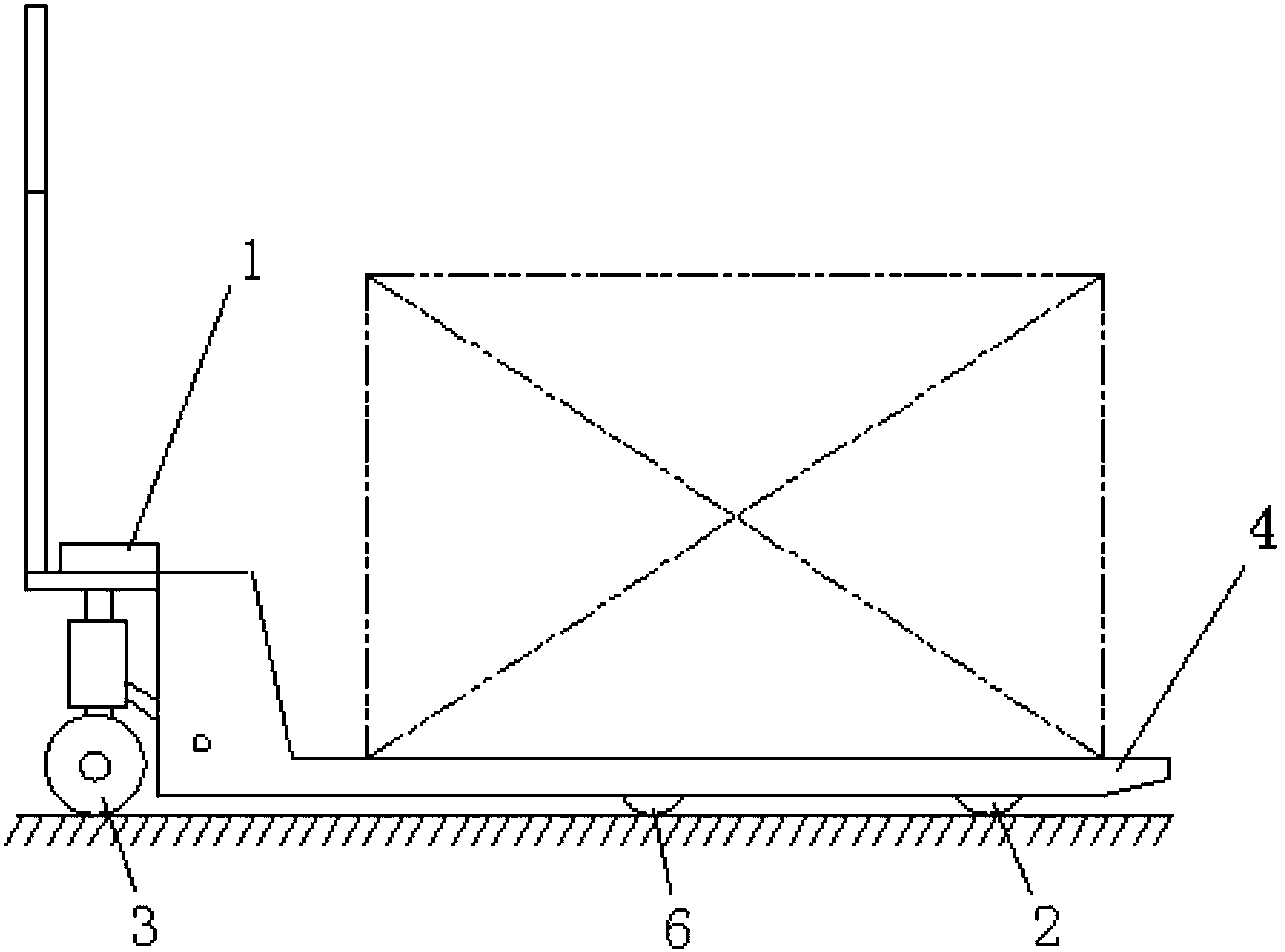

[0022] see figure 1 , 4 , 5, 6, a pallet truck with an auxiliary support wheel device, including a pallet truck 1, a support wheel 2 installed on the bottom surface of the pallet truck, a steering wheel 3 and a fork 4 at the front end of the pallet truck, the The bottom surface of the cargo fork 4 is provided with a roller cage 5 between the support wheel and the steering wheel, and the roller cage 5 is equipped with a roller 6, and the roller cage 5 is installed on the bottom surface of the cargo fork 4 through the base 7; The base 7 is installed on the bottom surface of the pallet fork 4 through screws 8, guide posts 9 are respectively fixed on both ends of the base 7, guide sleeves 10 penetrating through the roller cage are fixed on both ends of the roller cage 5, the described The guide post 9 extends into the guide sleeve 10 and the bottom end is locked by the limit nut 11. The roller cage 5 is mounted on the base 7 through the cooperation of the guide sleeve 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com