Non-oriented silicon steel with insulating coating containing organic coloring agent and preparation method thereof

A technology of organic colorant and oriented silicon steel, which is applied in coatings, chemical instruments and methods, layered products, etc., and can solve problems such as insufficient coloring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take the above 100 parts of zinc chromate semi-inorganic paint, add 0.5 parts of phthalocyanine blue water-based organic color paste, stir for more than 20 minutes to ensure uniform mixing, and then apply it to the surface of non-oriented silicon steel sheet through a coating machine, and then implement according to the comparison The curing process of Example 1 is cured, and the non-oriented silicon steel with the insulating coating containing the organic colorant can be prepared.

Embodiment 2

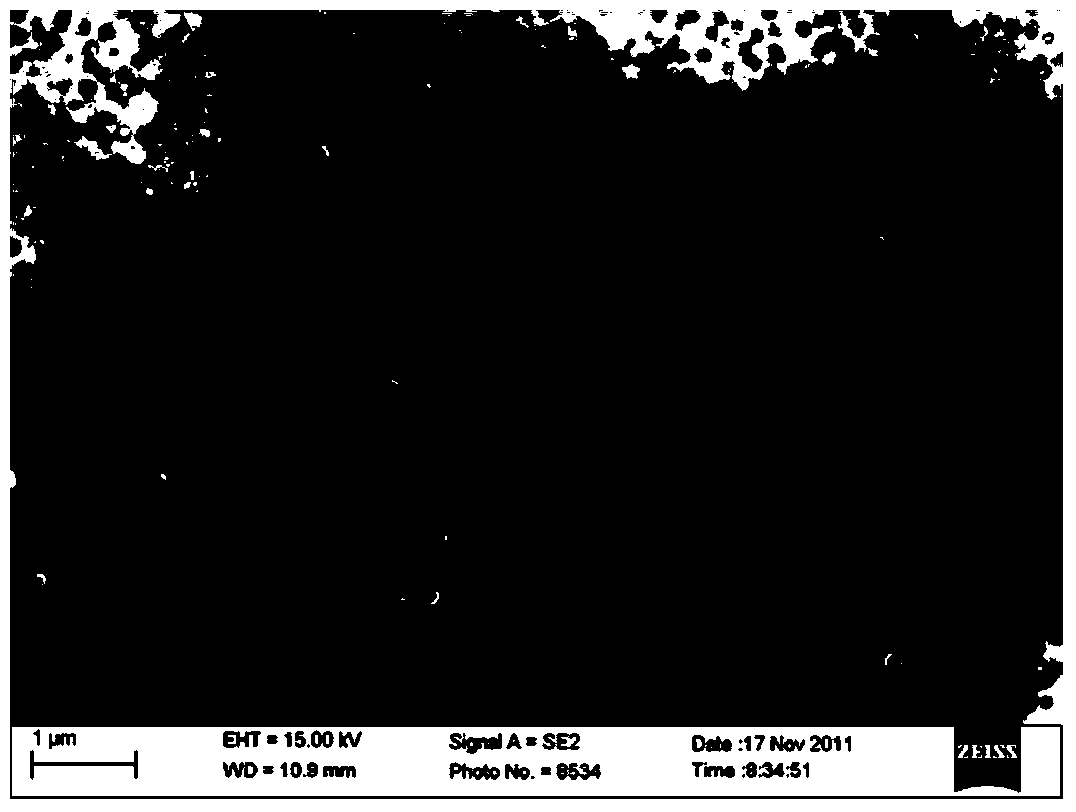

[0034] Get 100 parts of magnesium chromate semi-inorganic coatings, add 0.5 parts of phthalocyanine water-based organic color paste, stir for more than 20 minutes to ensure uniform mixing, and then apply it to the surface of non-oriented silicon steel by a coating machine, and then according to Comparative Example 2 After the curing process is cured, the non-oriented silicon steel containing the organic colorant in the magnesium chromate insulating coating can be prepared. The scanning electron microscope morphology of the coating is as follows figure 1 shown. The colorant particles are mainly distributed on the surface of the coating, which can improve the punching performance and welding performance of the coating.

Embodiment 3

[0036] Get 100 parts of zinc chromate semi-inorganic coatings, add 0.2 parts of fruit green water-based organic color paste, stir for more than 20 minutes to ensure uniform mixing, and then apply it to the surface of non-oriented silicon steel by a coating machine, and then according to Comparative Example 1 The non-oriented silicon steel with insulating coating containing organic colorant can be prepared after curing by advanced curing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com