Culture pond for culturing micro-algae

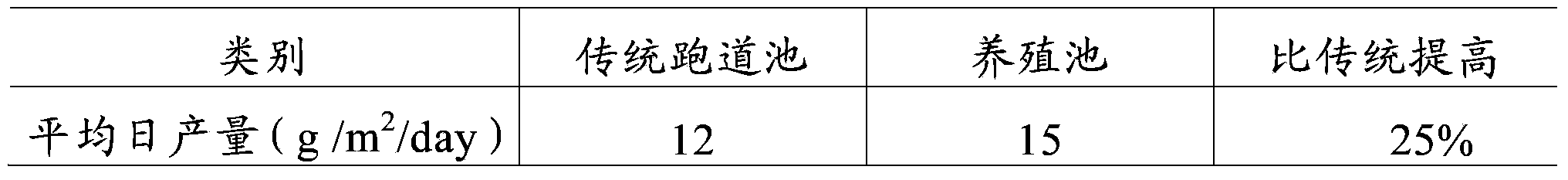

A technology for culturing microalgae and cultivating ponds, applied in the field of cultivating ponds, can solve problems such as large energy loss, large dead zone area, and strong algal fluid flow resistance, so as to accelerate the flow speed, increase the degree of turbulent swirl, and increase the algae yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

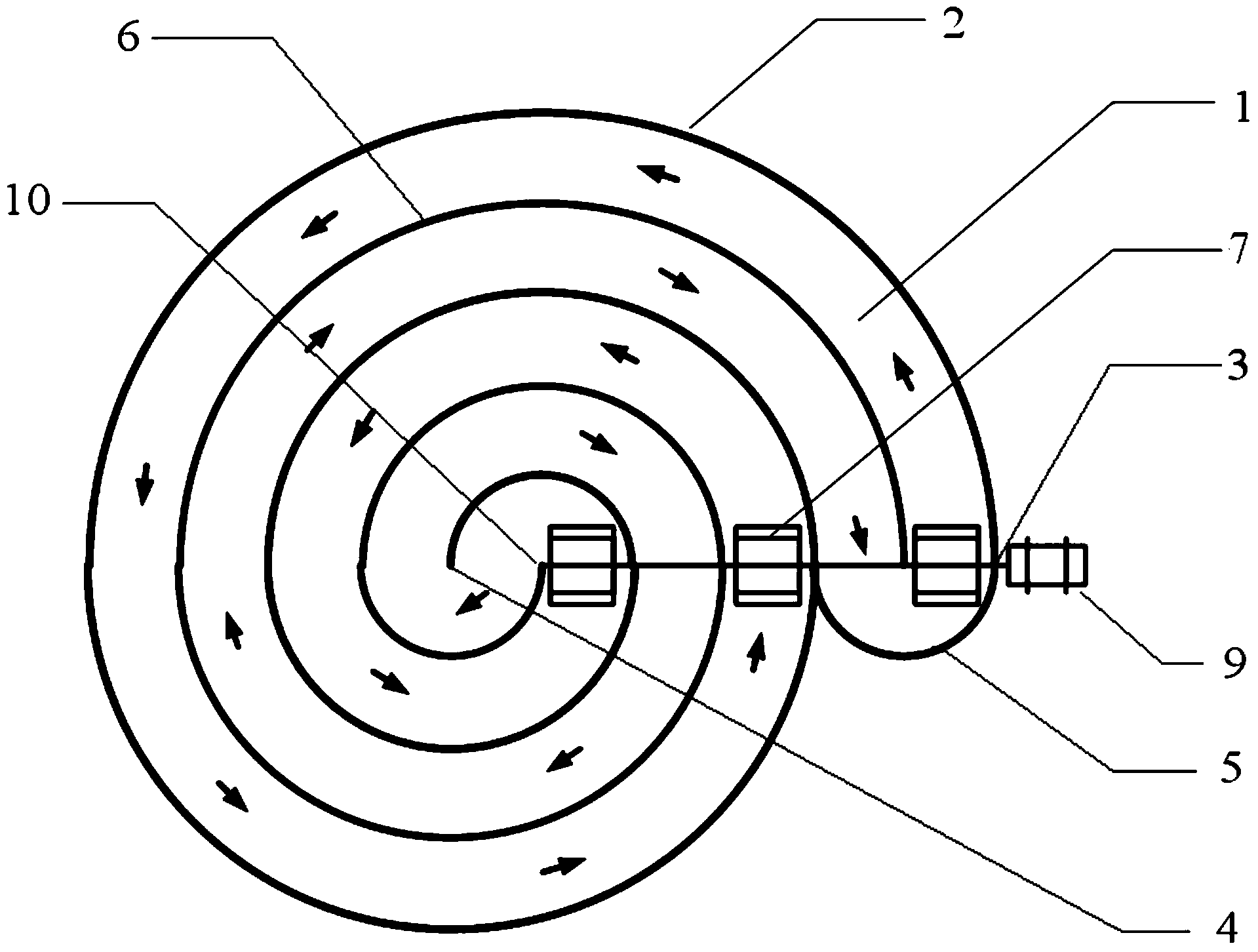

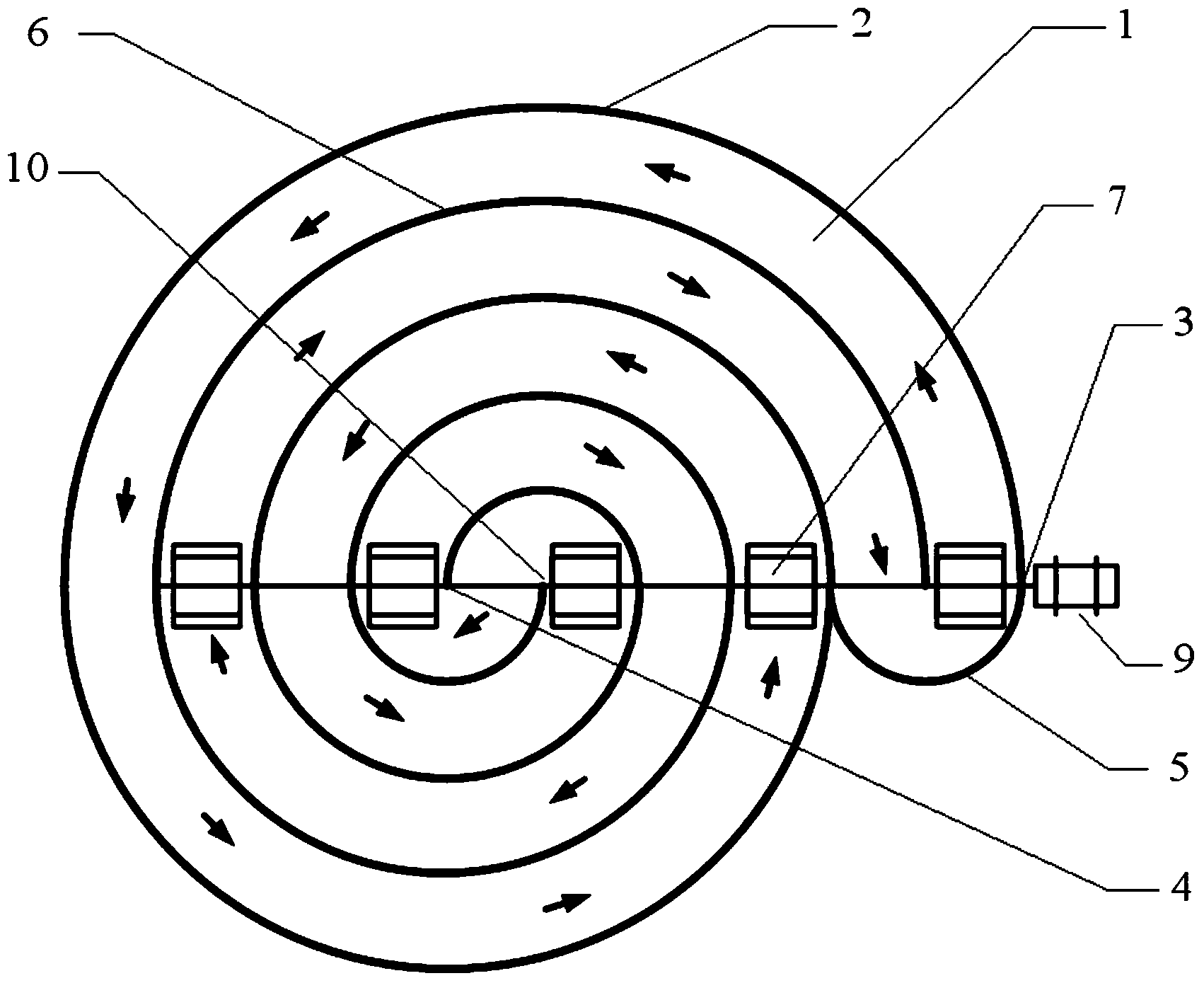

[0021] refer to figure 1 , the present invention is used for the culture tank of microalgae culture and comprises: pool bottom 1, the side wall 2 that is fixed on the pool bottom 1, along side wall 2, and the dividing plate 6 that extends at intervals with side wall 2, is positioned at Stirring paddle 7 between side wall 2 and partition 6 . Wherein, the outer end 3 of the side wall 2 is connected to the outer surface of the side wall 2 adjacent to the outer end 3, and the side wall 2 spirally extends along its longitudinal length direction.

[0022] Specifically, the culture pond is surrounded by a pond bottom 1 and a spiral side wall 2 fixed on the pond bottom 1 . Along the extension direction of the side wall 2, a partition 6 is provided at a distance from the side wall 2, that is, the partition 6 is also spiral. Preferably, along the longitudinal circumferential direction of the side wall 2, the distance from the partition plate 6 to the pool walls of the two adjacent sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com