High-permeability mask nonwoven fabric and manufacturing method thereof

A manufacturing method and technology of non-woven fabrics, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problem of not meeting the requirements of high penetration and high absorption of beauty liquid, non-woven fabrics with low toughness and skin-adherence, non-woven fabrics Problems such as low permeability, to achieve the effect of increasing strength, reducing anisotropy, and enhancing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

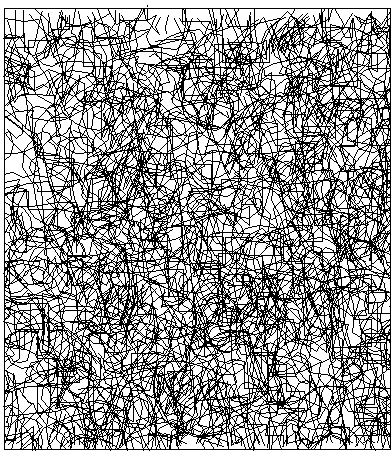

[0020] Embodiment 1: with reference to attached figure 1 . A kind of non-woven fabric of high-permeability film, comprising non-woven fabric layer; Non-woven fabric layer is made of short cellulose fiber as raw material, and each cellulose fiber is intertwined into high-permeability film non-woven fabric in disorder; the length of cellulose fiber is 13mm or 20mm.

Embodiment 2

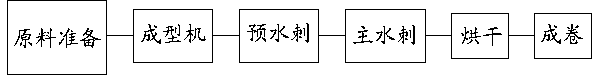

[0021] Embodiment 2: with reference to attached figure 2 . A kind of manufacture method of above-mentioned high permeable mask non-woven fabric, comprises the following steps:

[0022] ① Prepare raw materials, using two kinds of cellulose fibers with a length of 5-25mm as raw materials;

[0023] ② After mixing the two kinds of raw material fibers according to a certain ratio, the raw material fiber slurry is formed;

[0024] ③ The raw fiber slurry flows into the forming machine for carding, and dehydrates on the forming net to form the first layer of fiber web;

[0025] ④The forming net in the forming machine is inclined, and the angle between the forming net and the horizontal plane is 15°~30°. A high-pressure pre-spun thorn head is installed above the forming machine. The first layer of wet fiber web is spunlace pre-entangled;

[0026] ⑤ Raw material fiber slurry flows into the forming machine to form the second layer of fiber web on the basis of the first layer of fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com