Preparation method of natural multi-effect lip mask

A natural lip mask technology, applied in the field of natural multi-effect lip mask preparation, can solve the problems of lip skin damage and inability to clean deeply, and achieve the effects of improving skin condition, preventing melanin precipitation, and resisting free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

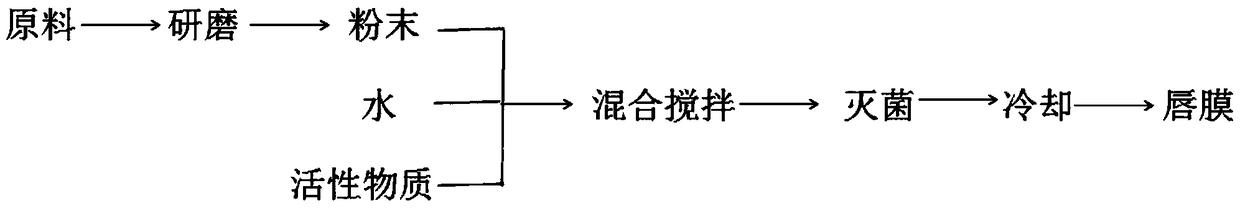

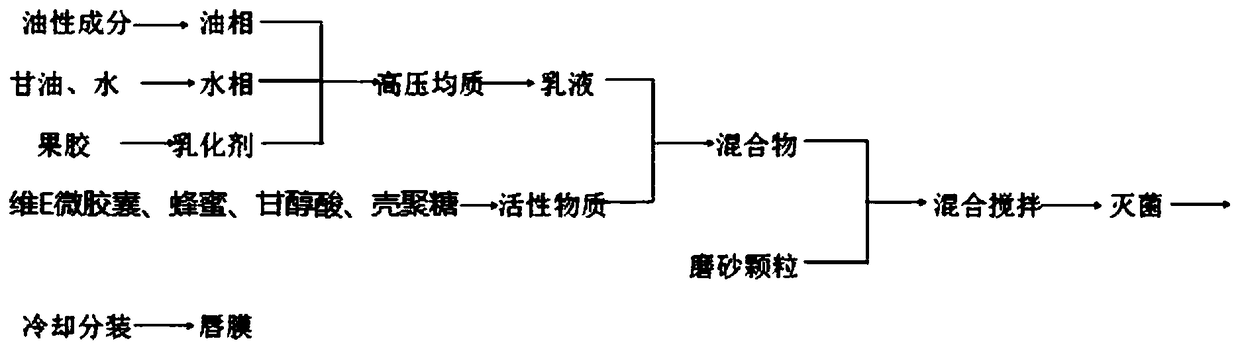

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of emulsion: 18.5g of olive oil and 11.5g of grapeseed oil were mixed according to the mass ratio of 4:2.5, heated to 85°C, and stirred evenly to form the oil phase. Mix 25g of glycerin and 40g of water as the water phase, 5g of pectin as the emulsifier, mix the oil phase, water phase and emulsifier, heat to 80°C, stir evenly, use a 26000rpm high-speed shear for 2min, and use a high-pressure homogenizer The machine can be circulated and homogenized 5 times under the pressure of 70MPa to obtain a uniform and stable oil-in-water emulsion;

[0031](2) Prepare vitamin E microcapsules: use chitosan and maltodextrin as wall materials to prepare vitamin E microcapsules by spray drying. The emulsifier uses lecithin and gelatin with a mass ratio of 4:2. : Maltodextrin: Vitamin E: Emulsifier = 3% : 70% : 15% : 12%. Vitamin E 1.5g, lecithin 0.8g and gelatin 0.4g are mixed, and high-speed shear stirring (13000r / min, 3min) obtains core material solution, then the ch...

Embodiment 2

[0038] (1) Preparation of emulsion: Mix 19.2g of olive oil and 12.8g of grapeseed oil in a mass ratio of 3:2, heat to 90°C, and stir evenly to form the oil phase. Mix 25g of glycerin and 35g of water as the water phase, 8g of pectin as the emulsifier, mix the oil phase, water phase and emulsifier, heat to 80°C, stir evenly, use a 30000rpm high-speed shear for 3min, and use a high-pressure homogenizer The machine can be circulated and homogenized 5 times under the pressure of 70MPa to obtain a uniform and stable oil-in-water emulsion;

[0039] (2) Prepare vitamin E microcapsules: use chitosan and maltodextrin as wall materials to prepare vitamin E microcapsules by spray drying. The emulsifier uses lecithin and gelatin with a mass ratio of 4:2. : Maltodextrin: Vitamin E: Emulsifier = 4% : 60% : 20% : 15%. Mix 2g of vitamin E, 1g of lecithin and 0.5g of gelatin, high-speed shear stirring (14000r / min, 3min) to obtain a core material solution, then add 5g of chitosan solution with...

Embodiment 3

[0046] (1) Preparation of emulsion: Mix 26.9 g of olive oil and 8.1 g of grape seed oil in a mass ratio of 5:1.5, heat to 75° C., and stir evenly to form an oil phase. Mix 15g of glycerin and 40g of water as the water phase, 10g of pectin as the emulsifier, mix the oil phase, water phase and emulsifier, heat to 75°C, stir evenly, use a 28000rpm high-speed shearer to cut for 2-3min, use high pressure The homogenizer circulates and homogenizes 5 times under the pressure of 70MPa to obtain a uniform and stable oil-in-water emulsion;

[0047] (2) Preparation of vitamin E microcapsules: use chitosan and maltodextrin as wall materials to prepare vitamin E microcapsules by spray drying. The emulsifier uses lecithin and gelatin with a mass ratio of 4:2, chitosan: malt paste Essence: vitamin E: emulsifier = 4%: 65%: 18%: 13%. Vitamin E 1.8g, lecithin 0.9g and gelatin 0.4g are mixed, and high-speed shear stirring (15000r / min, 3min) obtains core material solution, then the chitosan solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com