Electric heating rod group for emulsified asphalt tank of asphalt spreading paver

A technology of electric heating rods and emulsified asphalt, applied in immersion heating devices, roads, buildings, etc., to achieve the effects of reducing power, preventing local overheating, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

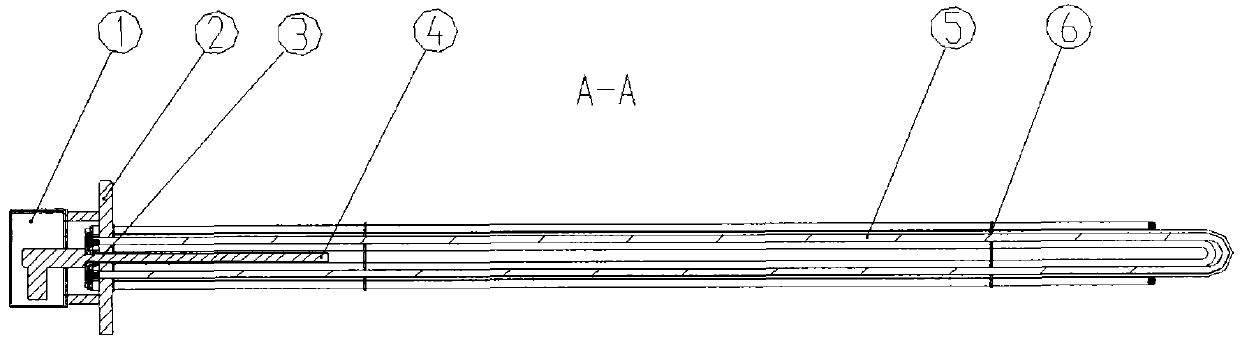

[0020] Below in conjunction with accompanying drawing, the application is described in further detail:

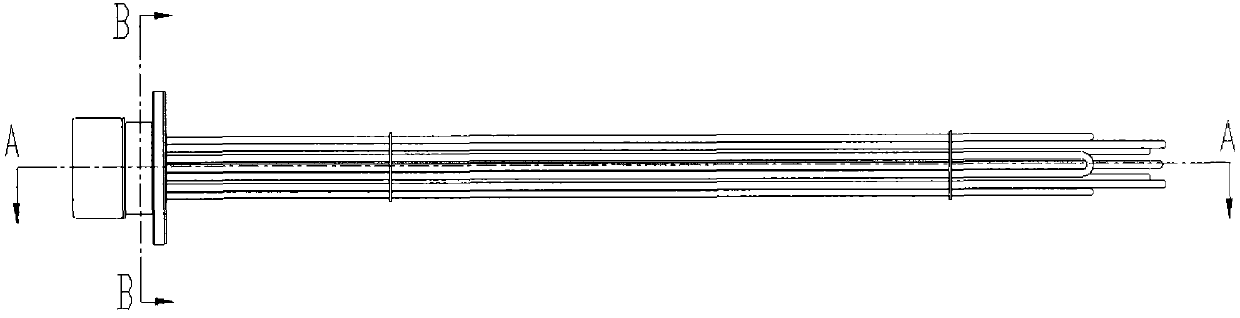

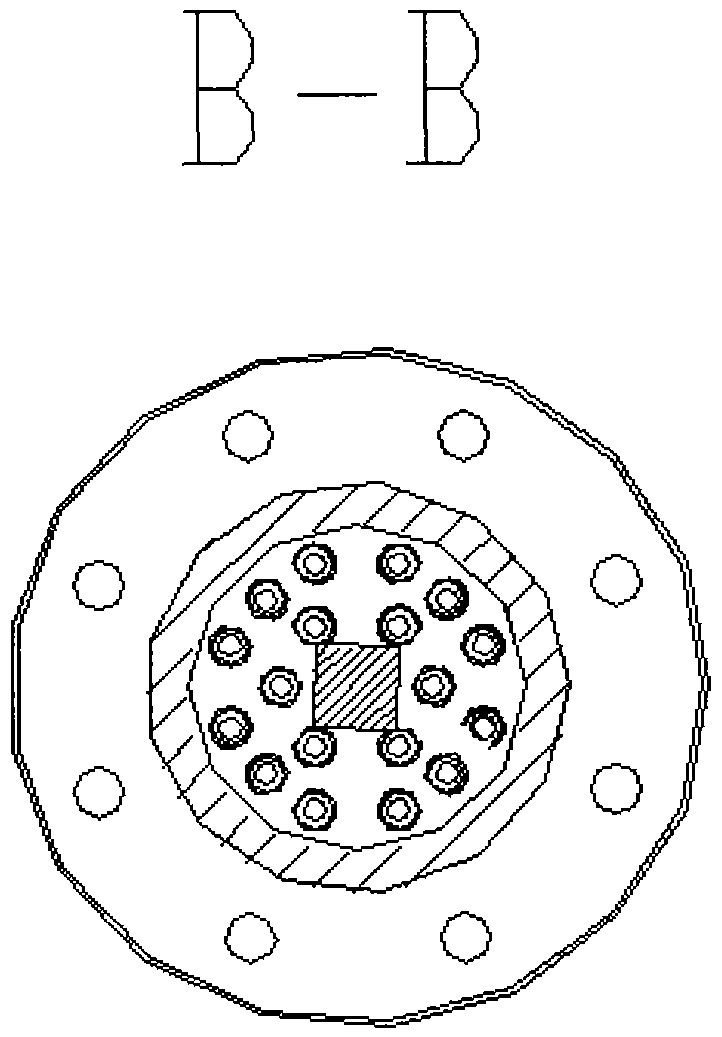

[0021] like figure 1 and figure 2 As shown, the electric heating rod group includes a junction box 1, a connecting flange 2, a short internal thread steel pipe 3, a temperature switch 4, a heating rod body 5, and a clamp 6, wherein the junction box 1 and the connecting flange 2 are connected by bolts. At the same time, the internal thread short steel pipe 3 is welded at the center of the connecting flange 2, and the temperature switch 4 is installed in the center of the heating rod group through the internal thread short steel pipe 3; the heating rod body 5 is composed of nine U-shaped heating rods with a circular cross section , The two ends of the U-shaped heating rod lead out the wiring; the power of each U-shaped heating rod is equal.

[0022] like image 3 As shown, the two ends of the U-shaped heating rod of the heating rod body 5 respectively pass through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com