PVC hole-pipe gravel pile and soft foundation processing method thereof

A technology of weak ground and crushed stone piles, which is applied in the field of weak ground treatment, can solve problems such as difficult control of engineering quality, bulging of broken stones, and limited improvement of the overall bearing capacity, and achieve the effect of simple construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0048] 1. PVC perforated pipe gravel pile

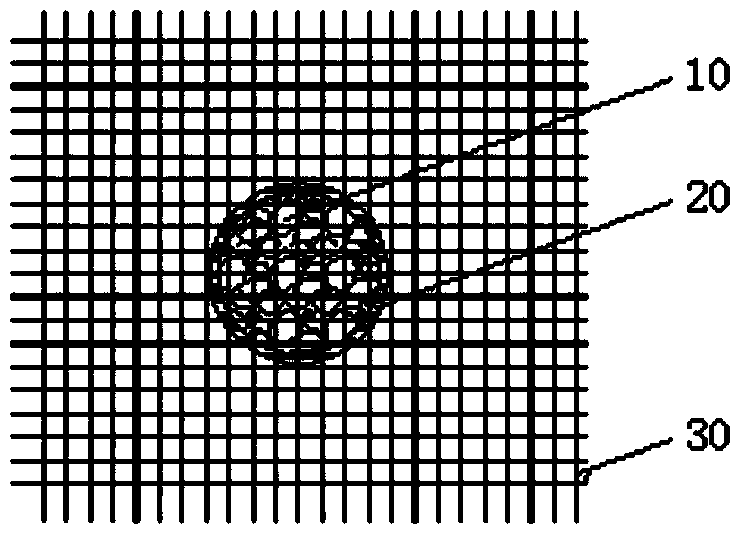

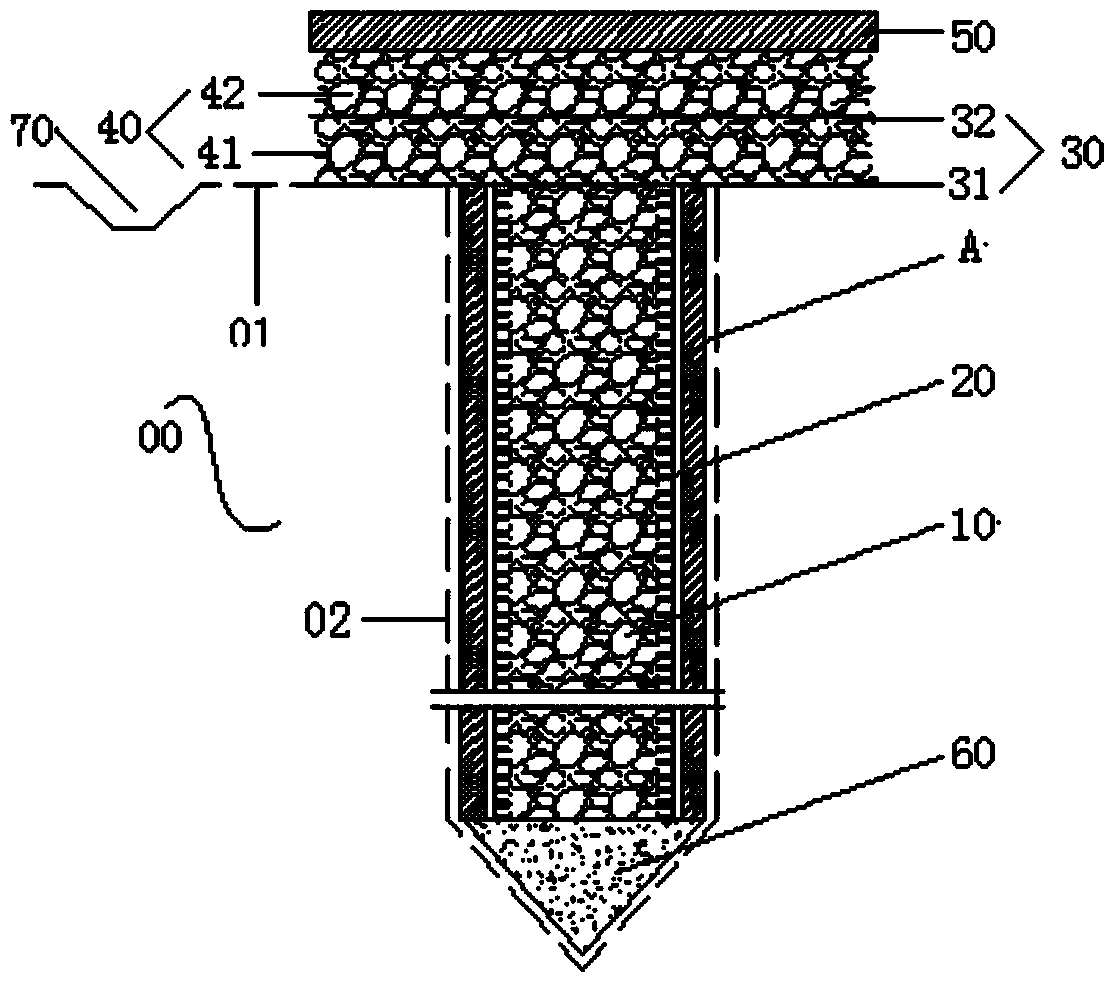

[0049] Such as figure 1 , 2 , placed in the underground hole 02 of the weak foundation 00, composed of gravel piles 10, PVC perforated pipes 20, steel-plastic geogrid 30, gravel layer 40, topsoil layer 50, concrete pile tip 60 and drainage system 70 The steel-plastic geogrid 30 includes the first steel-plastic geogrid 31 and the second steel-plastic geogrid 32, and the crushed stone layer 40 includes the first crushed stone layer 41 and the second crushed stone layer 42;

[0050] From bottom to top, the concrete pile tip 60 and the new pipe stone pile are connected to each other, and the new pipe stone pile includes a PVC perforated pipe 20 and a gravel pile 10 arranged in the pipe thereof;

[0051] A new type of cushion is connected to the top of the new pipe stone pile, and the new type of cushion is connected with the first steel-plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com