Part repair structure for steel lining of drainage pipeline

A technology for partial repair and drainage of pipes, which is applied in sewer systems, waterway systems, water supply devices, etc., and can solve problems such as pipe deformation, large disconnection, and large drainage pipe interface misalignment, etc., to achieve strong deformation resistance, long service life, The effect of high ring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

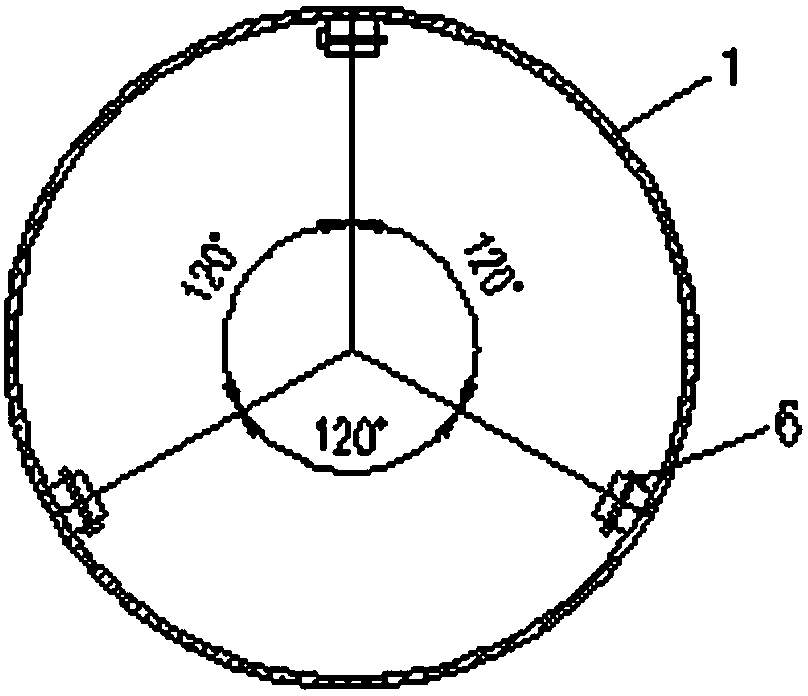

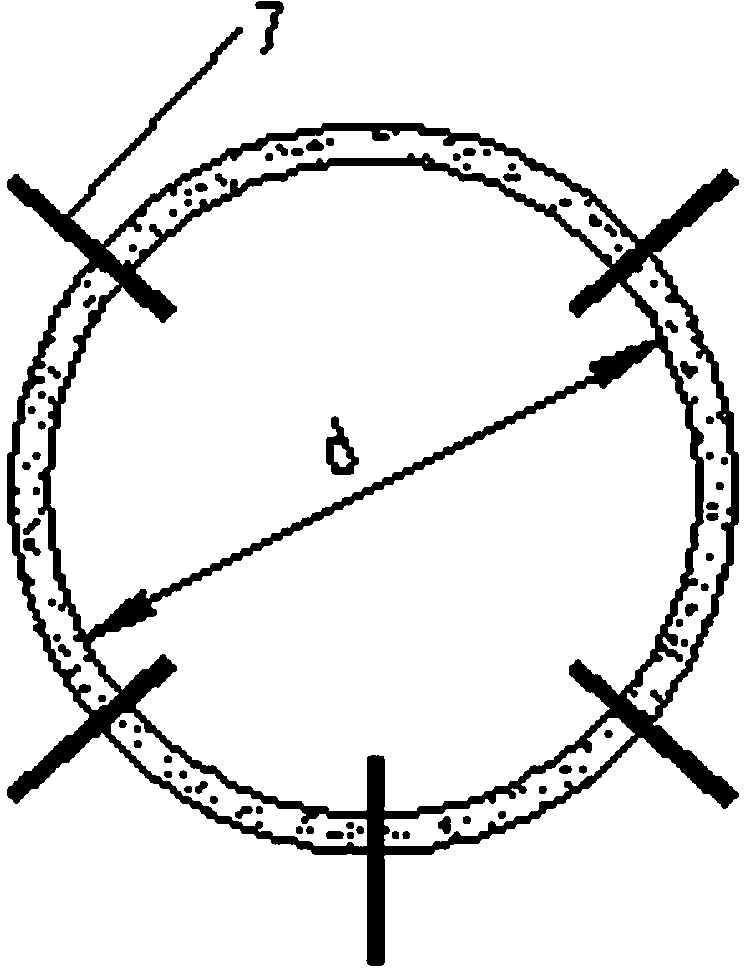

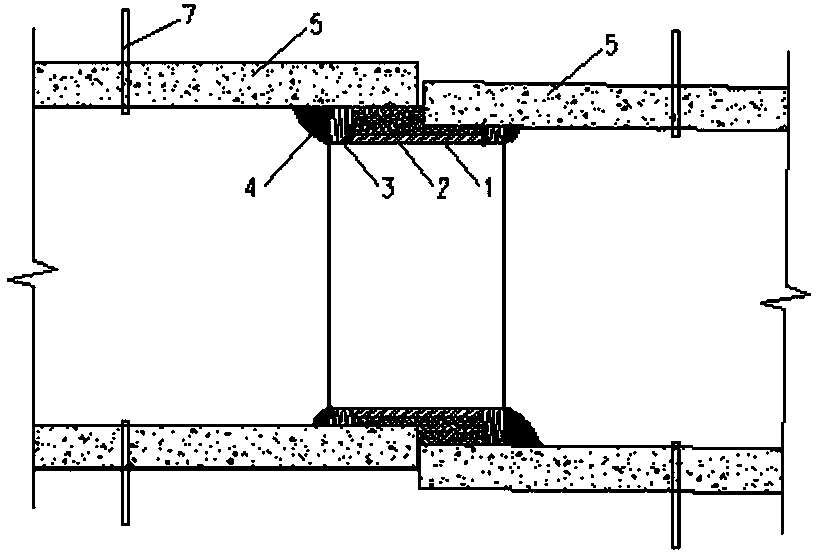

[0018] Such as figure 1 one image 3 As shown, it includes a steel-lined short pipe 1, polyurethane dense grouting 2, asbestos linoleum silk filling wiper tape 3, quick-drying cement chamfering 4, assembling fixing bolts 6 and pipe inner-outward grouting pipe 7.

[0019] The embodiment of the partial repair technology for the steel lining of the drainage pipe of the present invention will be described below with reference to the accompanying drawings.

[0020] Such as figure 1 one image 3 As shown, the partial repair structure of the steel lining of the drainage pipe according to the embodiment of the present invention includes a steel lining short pipe 1, polyurethane dense grouting 2, asbestos oil hemp silk filling wipe tape 3, quick-drying cement chamfer 4, pipe inner The grouting pipe 7 is drilled outward, and the short steel-lined pipe 1 is arranged in the pipeline 5 to be repaired. At the gap between the pipeline 5 to be repaired and the short steel-lined pipe 1, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com