Liquefied natural gas filling station BOG utilization system

A technology of liquefied natural gas and gas, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of waste of resources and only empty discharge, etc., and achieves easy disassembly and maintenance, small footprint, and guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

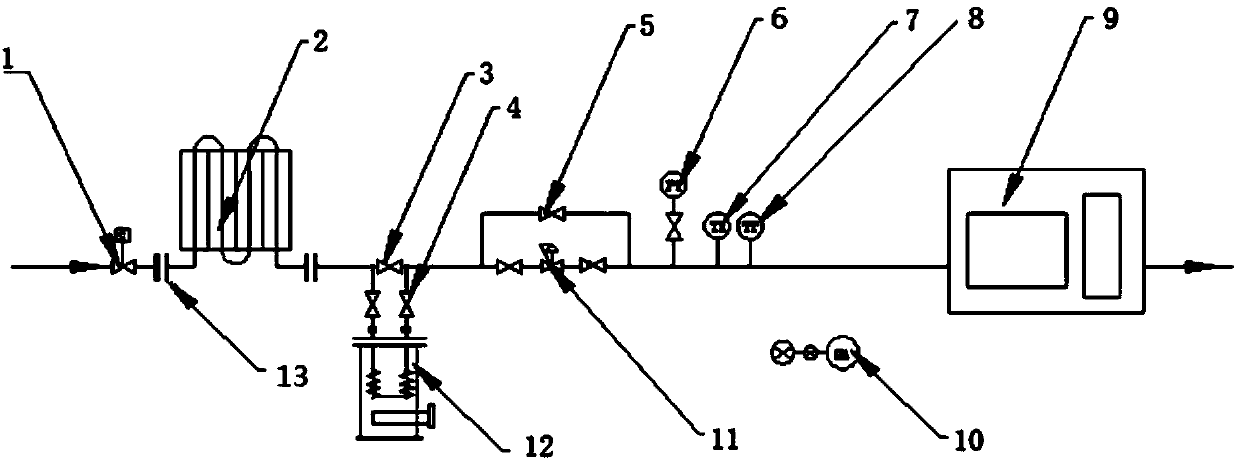

[0024] Such as figure 1 As shown, the BOG gas utilization system of the liquefied natural gas filling station of the present invention is connected with a low-temperature emergency shut-off valve 1, a BOG heater, a low-temperature stop valve 3, a pressure reducing valve 11, a pressure gauge 6, and a thermometer in sequence from the inlet of the main pipeline. 7. The temperature transmitter 8 and the natural gas compressor 9, the low temperature stop valve 3 is connected in parallel with a reheater, the pressure reducing valve 11 is connected in parallel with a bypass stop valve 5, and also includes a combustible gas alarm 10. The BOG heater is preferably an air-heated BOG heater 2. The reheater is preferably an electric hot water bath type reheater 12, and a valve 4 is provided at the inlet and outlet respectively. A valve 4 is provided at each end of the pressure reducing valve 11. The pressure gauge 6 is provided with a valve 4 on the pipeline connected with the main pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com