Adjustable smelting furnace

A smelting furnace, adjustable technology, applied in the field of smelting, can solve problems such as unreachable, achieve the effects of reducing labor costs, saving gas, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

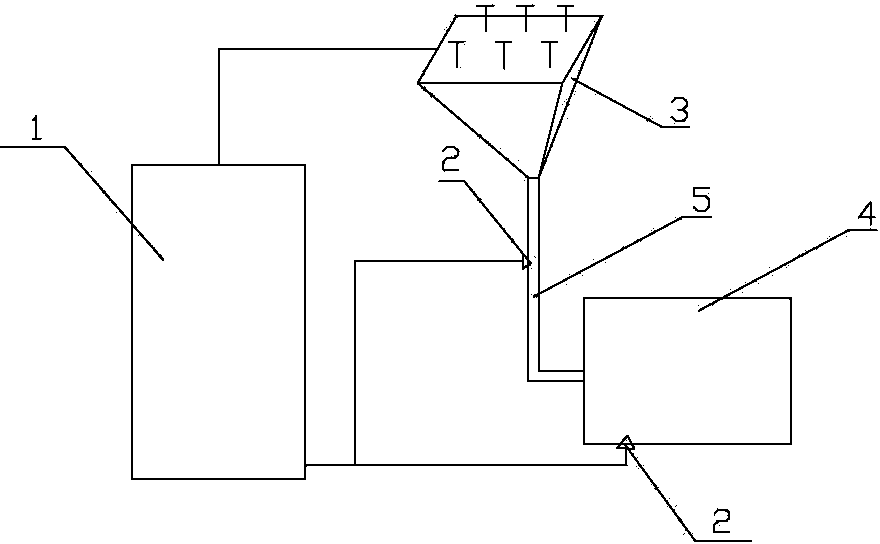

[0012] As shown in the figure, the present invention includes a burner 4, a mixed gas pipe 5 and a mixed gas valve group 3 connected to the burner 4 in sequence, and a controller 1 including a CO analyzer. The controller 1 communicates with a plurality of samplers 2 respectively arranged on the burner 4 and the gas mixture pipe 5 , and is connected to the gas mixture valve group 3 through a control circuit at the same time. The gas mixture valve group 3 includes a plurality of valves that can act independently, and can be controlled to open and close respectively. The above-mentioned controller 1 also contains a microcomputer system to make the control more precise and stable.

[0013] The working principle of the present invention is: when the smelting furnace is working, each part of the smelting furnace is automatically sampled through the sampler, and the CO analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com