Super-large bearing vibration noise quality detector

A bearing vibration, super-large technology, applied in vibration testing, mechanical bearing testing, measuring devices, etc., can solve the lack of basis to restrict the design innovation and transformation of large bearing products, affect the market share of bearing enterprises, and the hidden dangers of bearing enterprise product quality, etc. problems, to achieve the effect of powerful functions, reduced detection difficulty, and easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

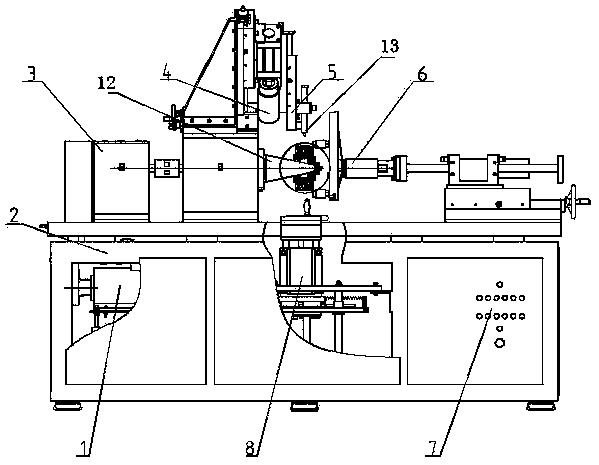

[0012] In order to deeply understand the structure of the super-large bearing vibration and noise quality inspection machine, combined with figure 1 described as follows:

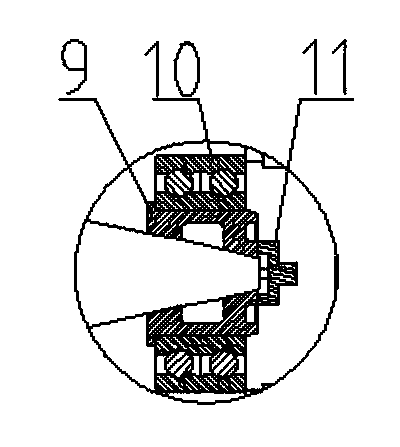

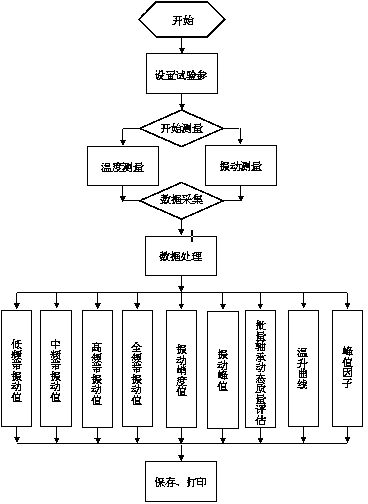

[0013] Super-large bearing vibration and noise quality inspection machine, composed of a driving mechanism 1, a body 2, a spindle transmission mechanism 3, a radial loading mechanism 4, an axial loading mechanism 6, a sensor adjustment mechanism 5, an auxiliary loading and unloading mechanism 8, and an electrical control system 7; The driving mechanism 1 is connected to the main shaft 12 through the main shaft transmission mechanism 3, the main shaft 12 is covered with a spring mold 9, the bearing 10 is loaded into the spring mold 9, and the locking nut 11 is used to lock the bearing 10; the auxiliary loading and unloading mechanism 8 is located under the bearing 10, And hold up the bearing 10; the radial loading mechanism 4 is located above the bearing 10, and loads a radial load to the bearing 10; the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com