Sagger crack detection base platform

A crack detection and abutment technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of no unified damage judgment standard, large radiation detection, high labor intensity, etc., to ensure accuracy, ensure comprehensiveness, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

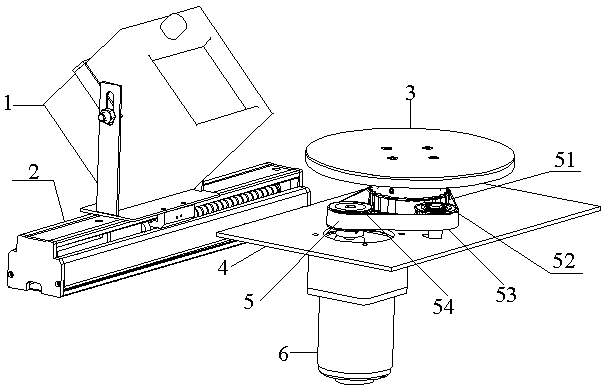

[0021] Such as figure 1 The shown sagger crack detection base includes a rotating device for rotating the object to be tested and an image acquisition device located on one side of the rotating device. There is a photoelectric sensor on the production line, which can judge whether the sagger enters the detection range, so as to ensure the accuracy of image collection.

[0022] Further, the rotating device includes a rotating motor 6, a synchronous belt transmission mechanism 5 connected to the power output end of the rotating motor, and a rotating disk 3 fixed on the synchronous belt transmission mechanism. Preferably, the rotating motor 6 is a servo motor. Specifically, by setting the rotation angle of the servo motor 6, it drives the synchronous transmission mechanism 5 to work, so that the rotating disk 3 on which the sagger to be tested is placed rotates 90° sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com