Positioning method for groove weld defects of large-wall-thickness pipe fitting

A technology of groove welds and positioning methods, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using radiation, and material magnetic variables, etc. Efficiency and accuracy cannot be guaranteed, and achieve the effects of improving efficiency, shortening production cycle, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for locating a groove weld defect of a large-wall-thickness pipe fitting, the method comprising the following steps:

[0028] a. After the groove weld of pipe fittings is welded according to the welding process, the welding surface shall be polished to ensure that the wall thickness difference within the range of 13mm on both sides of the weld and the groove is controlled to be ≤3mm;

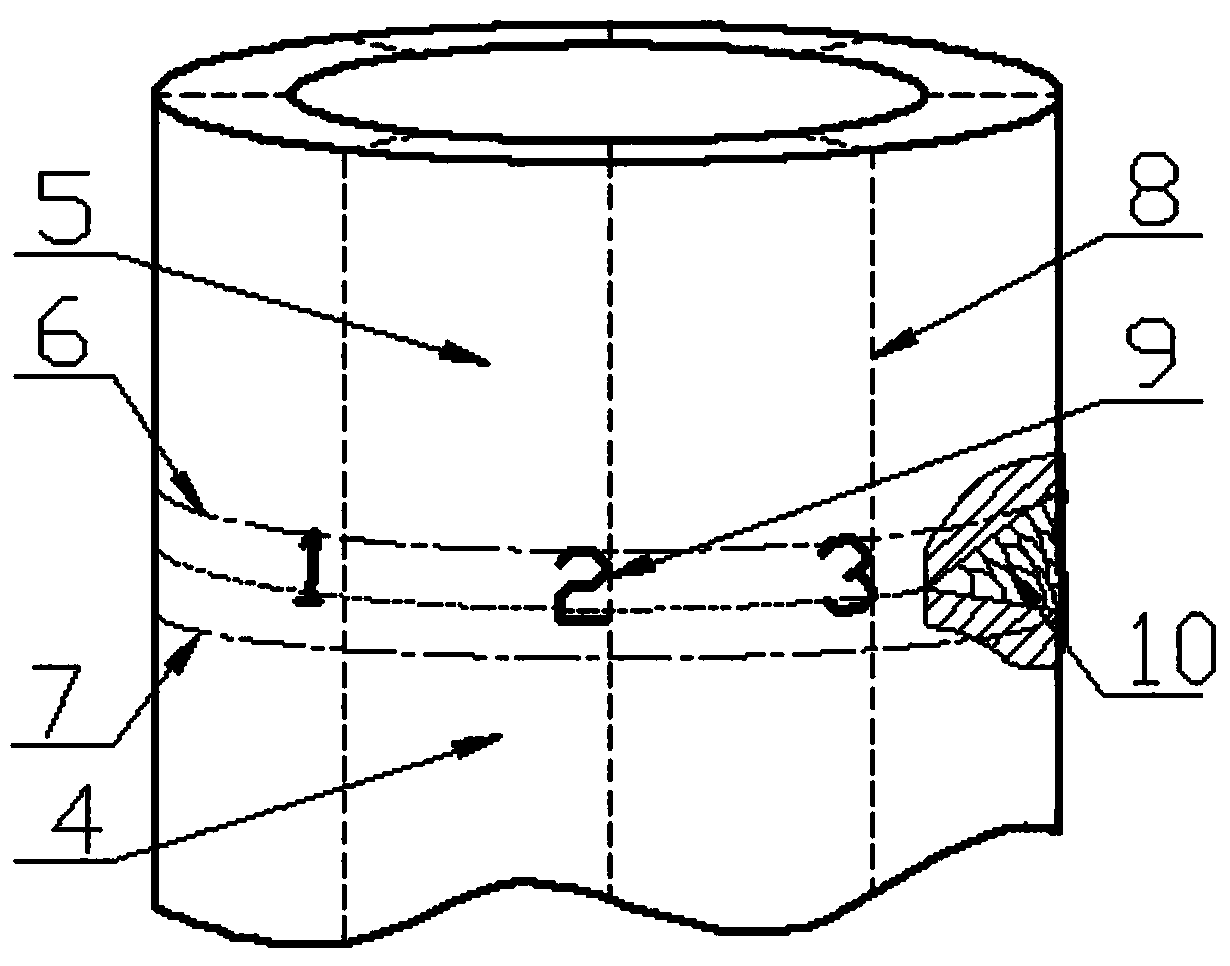

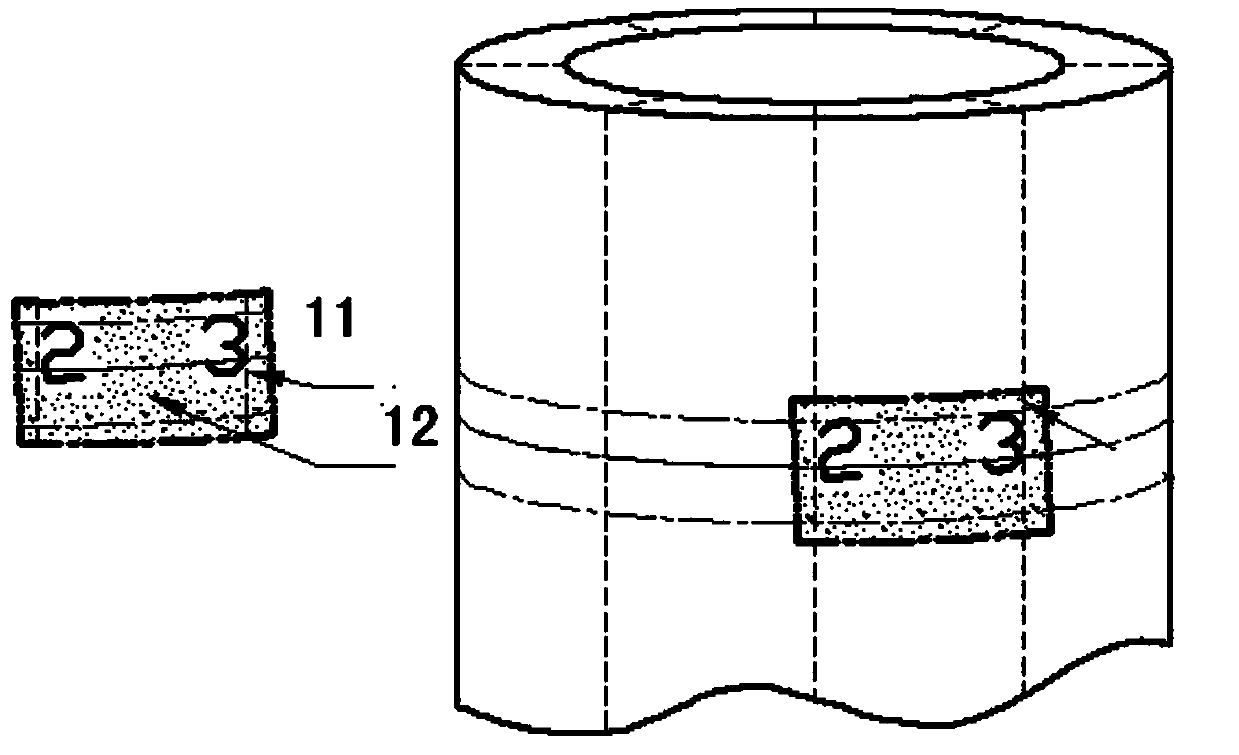

[0029] b. Evenly distribute the welding seam of the pipe into 8 equal parts, and mark the area, such as figure 1 Shown: Numbering is carried out in accordance with Arabic numerals, such as 1~2, 2~3...8~1. After the marking is completed, the weld seam shall be inspected according to the customer's specifications, and the negative film shall be reviewed after the inspection is completed;

[0030] c. Correspond the radiographic flaw detection film with the digital mark of the casting area boundary, mark the defect position mark on the surface of the nozzle weld, and then the single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com