Filling method of redundant graphs

A technology of redundant graphics and filling methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low filling rate, inability to fill, and influence on the uniformity of silicon wafers, so as to improve uniformity and production Process, improve the effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] The invention provides a redundant filling method, comprising the following steps:

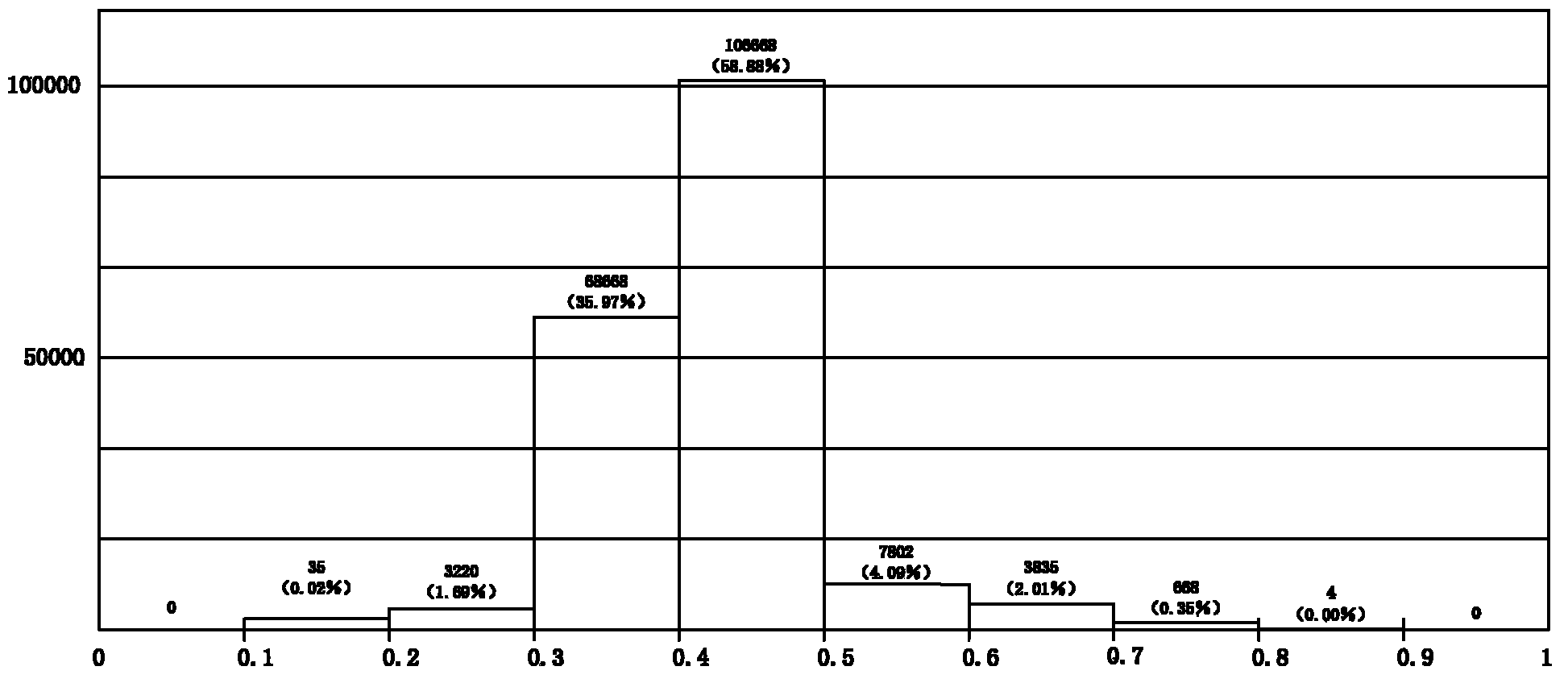

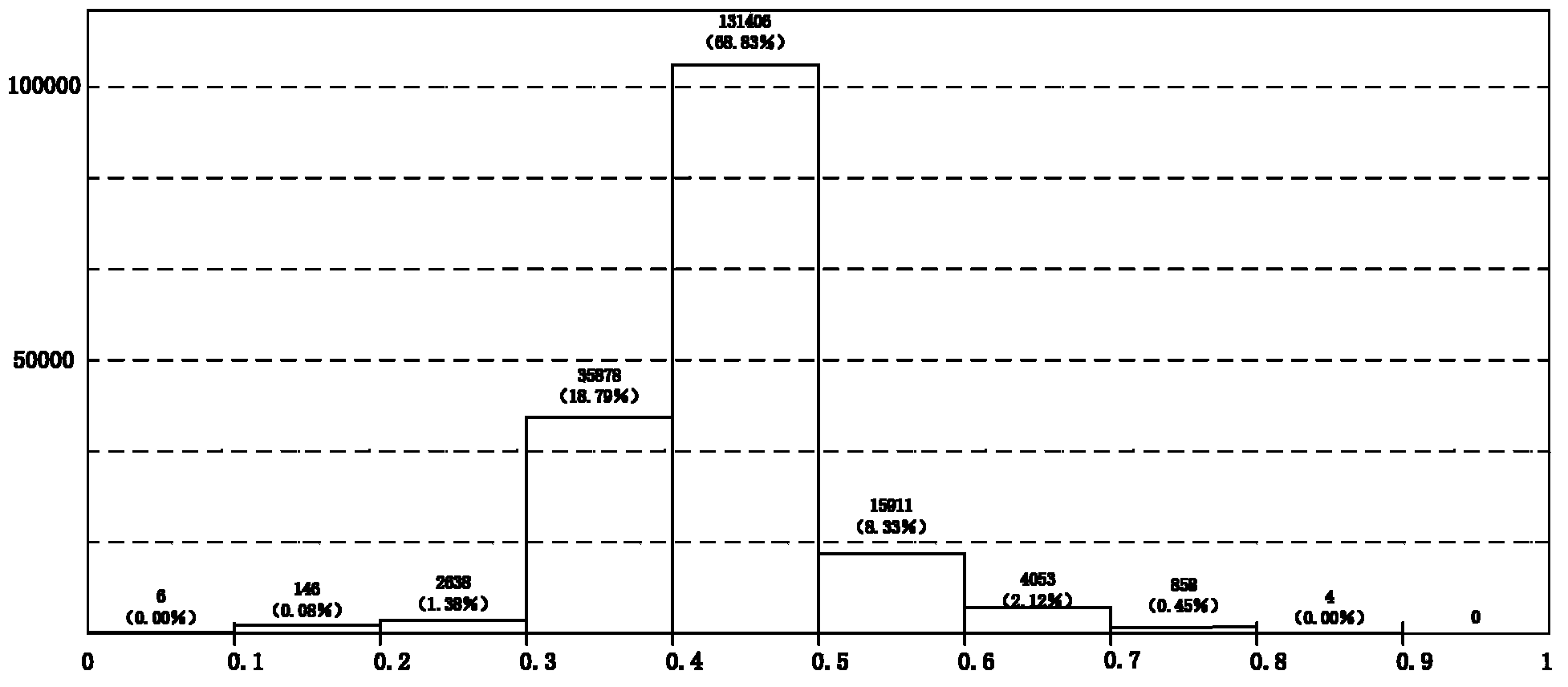

[0027] A layout to be filled is provided, and a main graphic is set on the layout. Then divide the layout into open area and non-open area. The criterion for judging is to set a value range d (0.1um<d<100um) according to the layout and process requirements. If the distance between an area and the main graphic is greater than d, the area is an open area; if the distance between an area and the main graphic is If it is less than or equal to d, the area is not an open area.

[0028] Different filling methods are used for filling according to different areas: the traditional redundant graphic filling is used for empty areas, that is, one or more fixed-size rectangles or polygons are used for redundant graphic filling; and for non-empty areas including The em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com