Seedling transplanting machine

A technology for transplanting machines and seedlings, which is applied in the field of seedling transplanting machines, which can solve the problems of inability to supply seedlings, increase the rotational load, and difficulty in reaching the cultivation depth adjustment rod, etc., and achieve the effect of simple and cheap production and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Embodiments of the present invention will be described below with reference to the drawings.

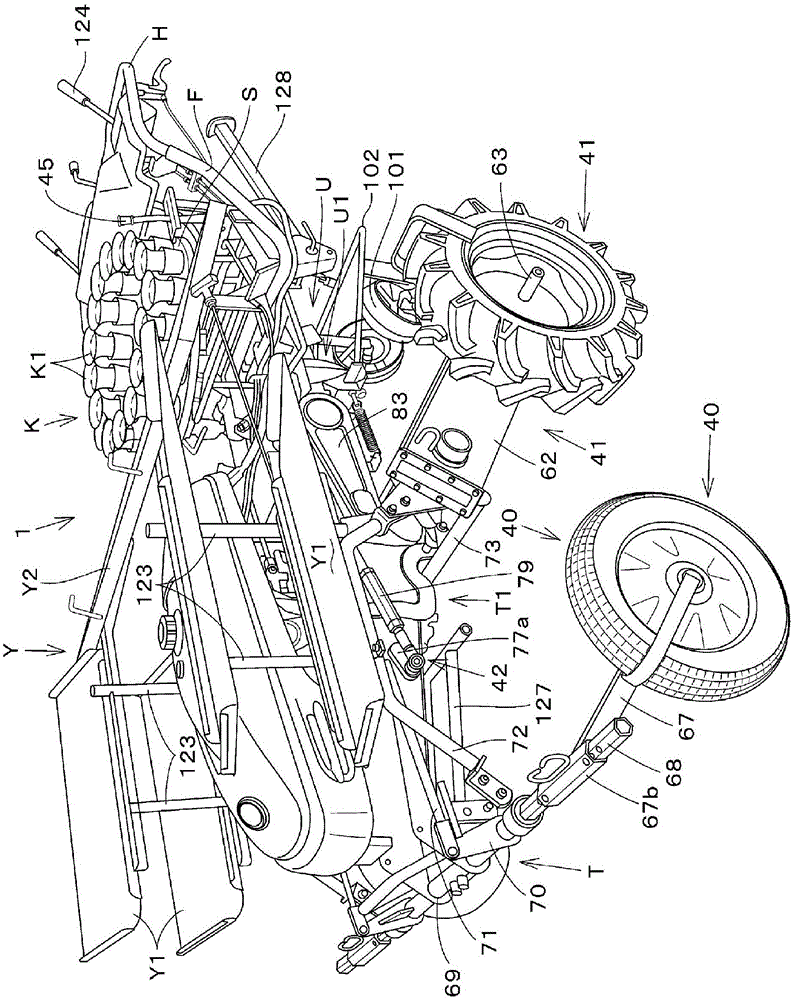

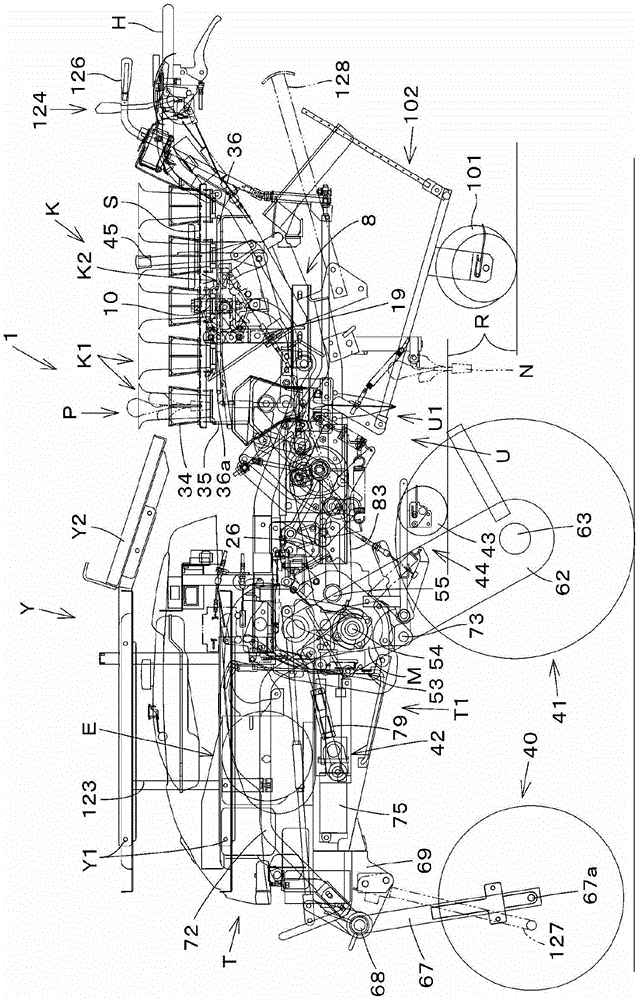

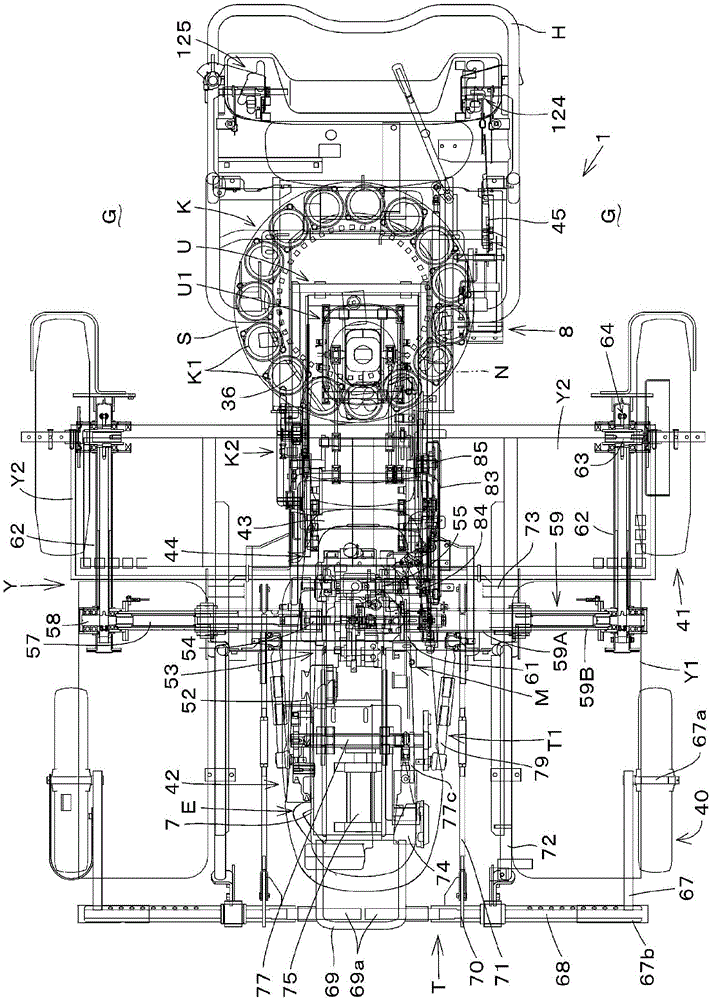

[0079] exist Figure 1~3 1 shows an example of a walking-type seedling transplanter 1 that moves along the longitudinal direction across the ridge R and cultivates unit-shaped seedlings such as tobacco seedlings and vegetables, seedlings with soil blocks, and seedlings in pots at predetermined intervals.

[0080] This seedling transplanting machine 1 generally has: a mobile body T that can travel; a rice shoot cultivation device U installed on the rear portion of the mobile body T; The seedling supply device K of the device U;

[0081] The platform 7 of the mobile body T protrudes forward from the transmission M, and an engine (drive source) E is mounted on the top thereof. The rear end of the frame 8 is connected with the joystick H, and the front wheel (front traveling device) 40 and the rear wheel (rear traveling device) 41 are suspended by the gearbox M and the platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com