Environment-friendly dumbbell and production method of environment-friendly dumbbell

An environment-friendly, dumbbell technology, applied in the direction of dumbbells, heavy objects, etc., can solve the problems of inconvenient placement and carrying, low efficiency, high cost, etc., and achieve the effects of energy saving, environmental protection, rust prevention, and injury reduction in processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

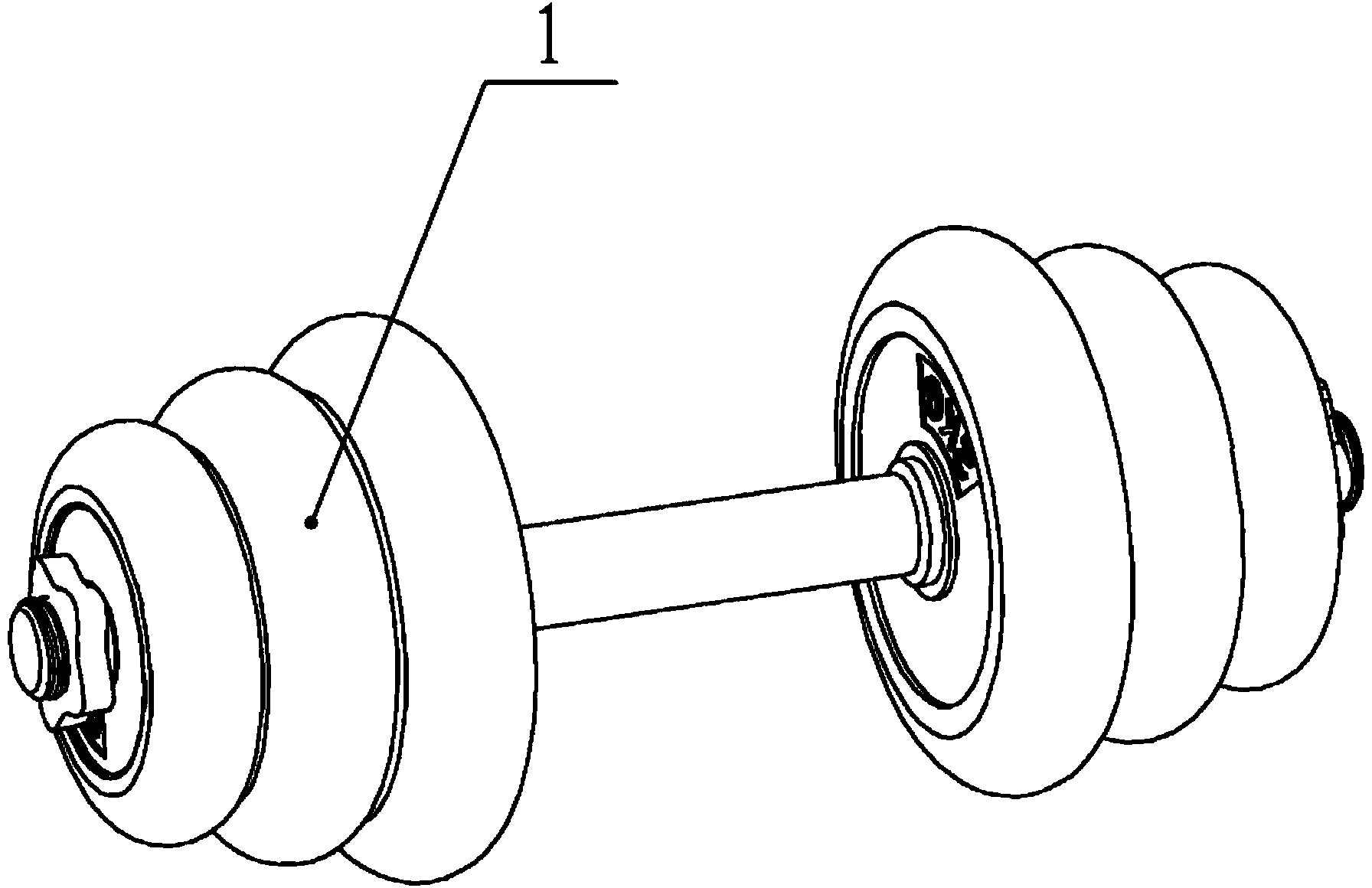

[0015] An environment-friendly dumbbell, comprising a dumbbell handle body, the dumbbell handle body including a shell 1 and a filler, the shell 1 component: low-density high-pressure polyethylene 34%-36%, color masterbatch 2.9%-3.1%, Desiccant 1.9%-2.1%, the rest is high-density low-pressure polyethylene; the filler components: gelling material 18%-21%, superplasticizer 3%-4%, mixing water 6%-9%, The rest is aggregate. The aggregate is iron powder or iron sand.

[0016] A processing technology for processing the dumbbell handle body according to claim 1, comprising the steps of:

[0017] (1) Blow molding: Mix the high and low pressure polyethylene particles, desiccant and color masterbatch according to a reasonable formula through a mixer, and make a semi-finished shell through an automatic blow molding machine, and trim and drill holes;

[0018] (2) Filling: Prepare high-strength concrete through mixing equipment according to a reasonable formula of various filler material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com