Flocking structure of flocking machine

A flocking machine and flocking technology, applied in the flocking structure field of the flocking machine, can solve the problems of fluff flying in the flocking workshop, low flocking efficiency, and poor working environment in the workshop, so as to reduce the cost of fluff and the working environment. Good, ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

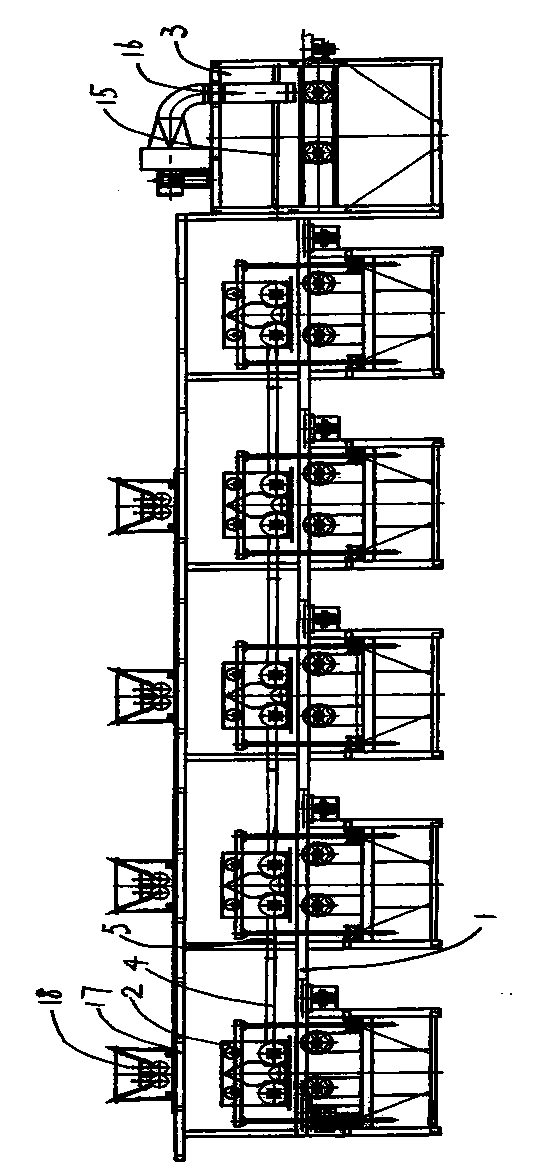

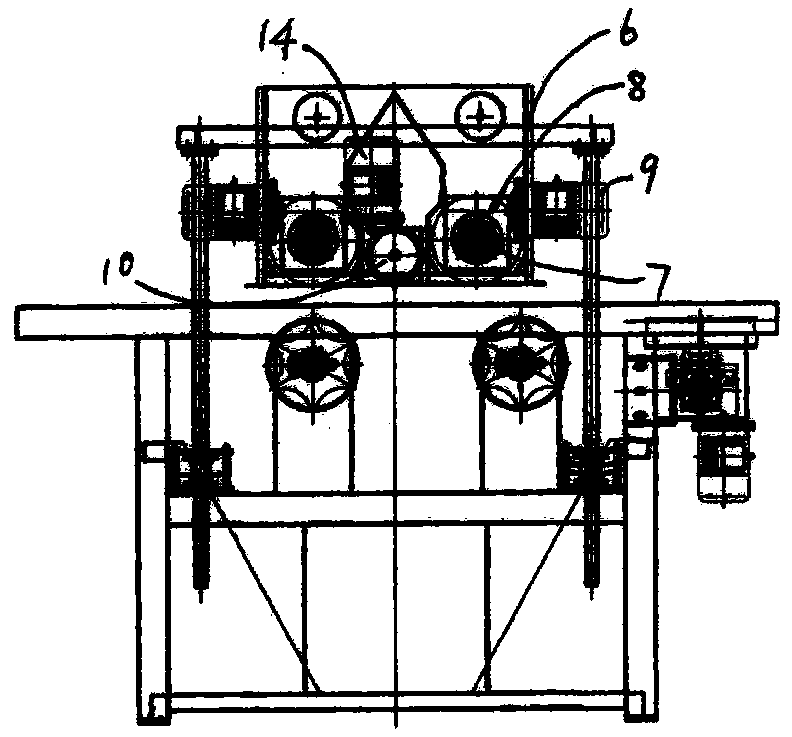

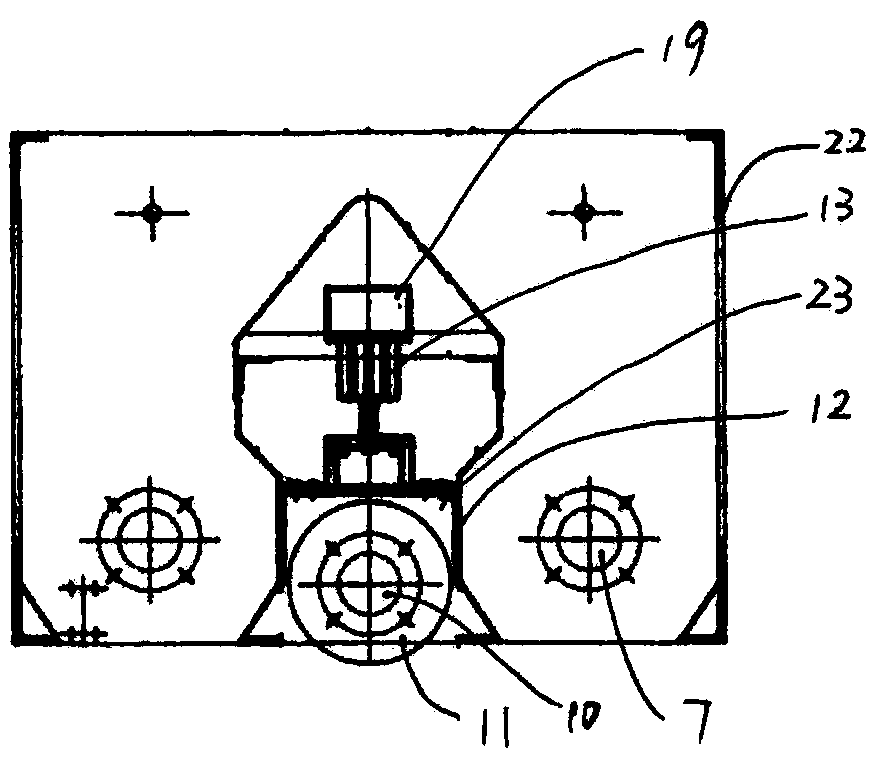

[0018] See Figure 1 ~ Figure 4 , which includes a cloth conveying pipe 1, a flocking chamber 2, and a recycling flocking chamber 3. The cloth conveying pipe 1 is evenly distributed with flocking chambers 2, and the rear of the last flocking chamber 2 is provided with a recycling flocking chamber 3, which is relatively The overall structure of metal plate 4 and glass plate 5 is arranged above the cloth delivery pipe between adjacent flocking rooms 2, one end of metal plate 4 is connected to one side vertical plate of one of the flocking rooms 2, and the other end of metal plate 4 One end of the glass plate 5 is connected, and the other end of the glass plate 5 is connected to the corresponding side vertical plate of another flocking room 2. Each flocking room 2 includes a corresponding shell 6, and the inside of the shell 6 is provided with two rotating rollers arranged in parallel. 7. The brushes 8 are correspondingly set on the rotating rollers 7 respectively, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com