Equipment for defect detecting and defect rejecting of hollow capsule

A hollow capsule and defect detection technology, which is used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of large floor space, rejection failure, and jitter of collection position, and achieves small floor space and simple structure. , the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

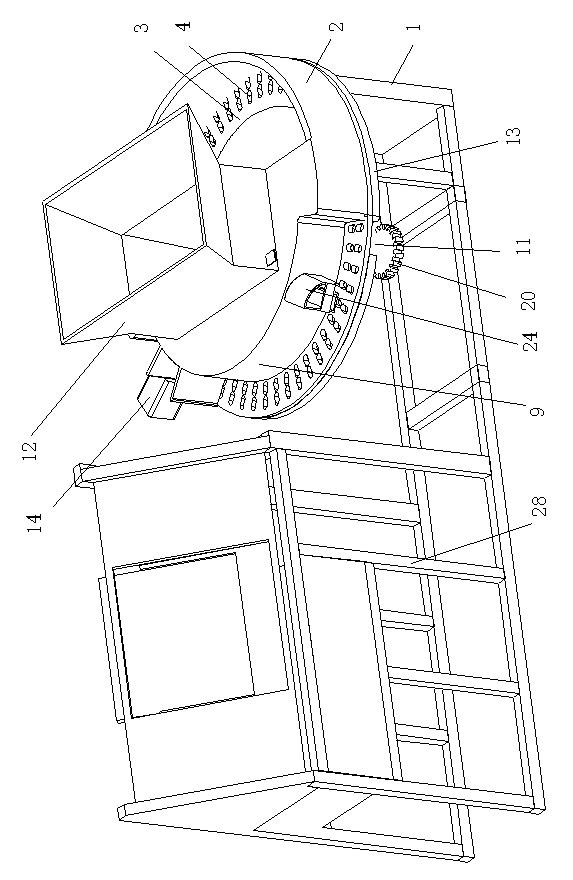

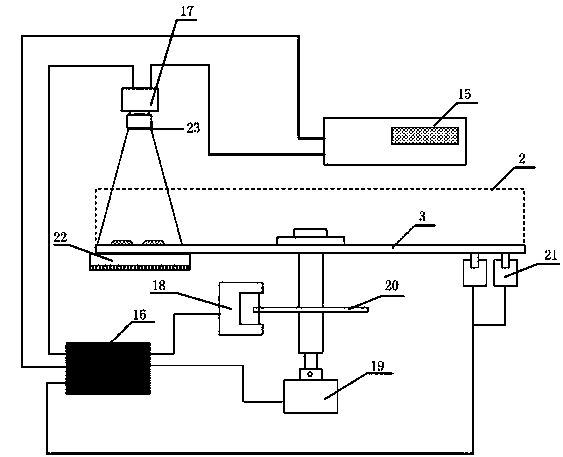

[0035] Such as figure 1 As shown, it is a schematic structural diagram of an embodiment of the hollow capsule defect detection and defect removal device of the present invention. The hollow capsule defect detection and defect removal equipment of this embodiment includes a frame 1 on which a feeding device and a feeding device are arranged.

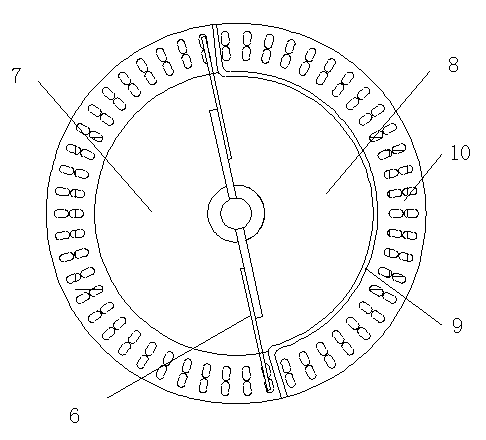

[0036] The feeding device includes a storage cabin 2 arranged below the feeding device, a feeding turntable 3 positioned at the bottom of the storage cabin 2, a capsule tray 13 for supporting the feeding turntable 3 and a drive mechanism for driving the rotation of the feeding turntable 3, the feeding turntable 3 is provided with a hole 4 for storing empty capsules for at least one week, and the storage compartment 2 is provided with a cleaning mechanism for cleaning the empty capsules not in the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com