A kitchen food waste disposer with automatic separation of oil and water residues

A food waste treatment and automatic separation technology, applied in the direction of liquid separation, separation methods, solid waste removal, etc., can solve problems such as unsanitary, pollute the environment, block sewers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

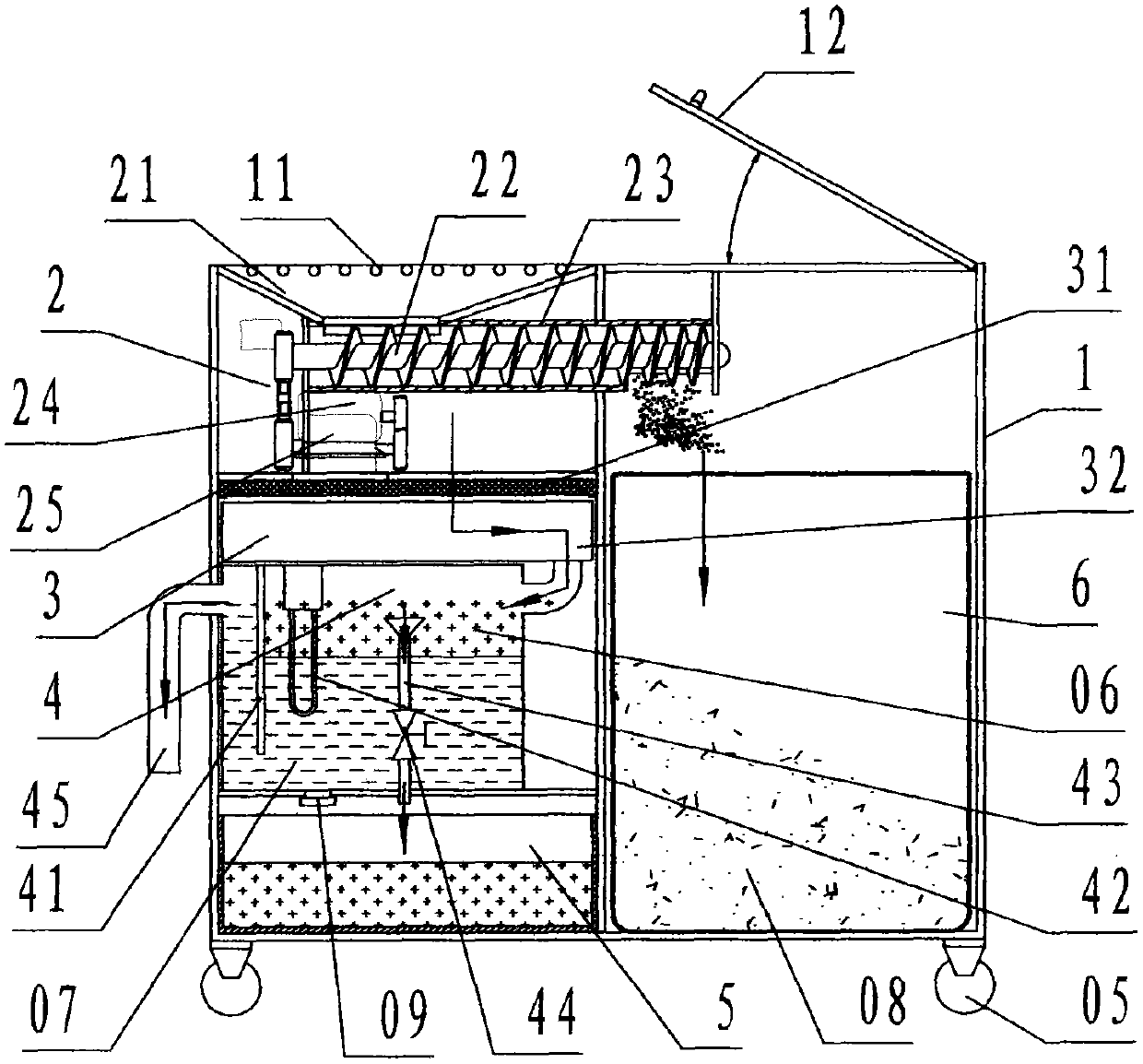

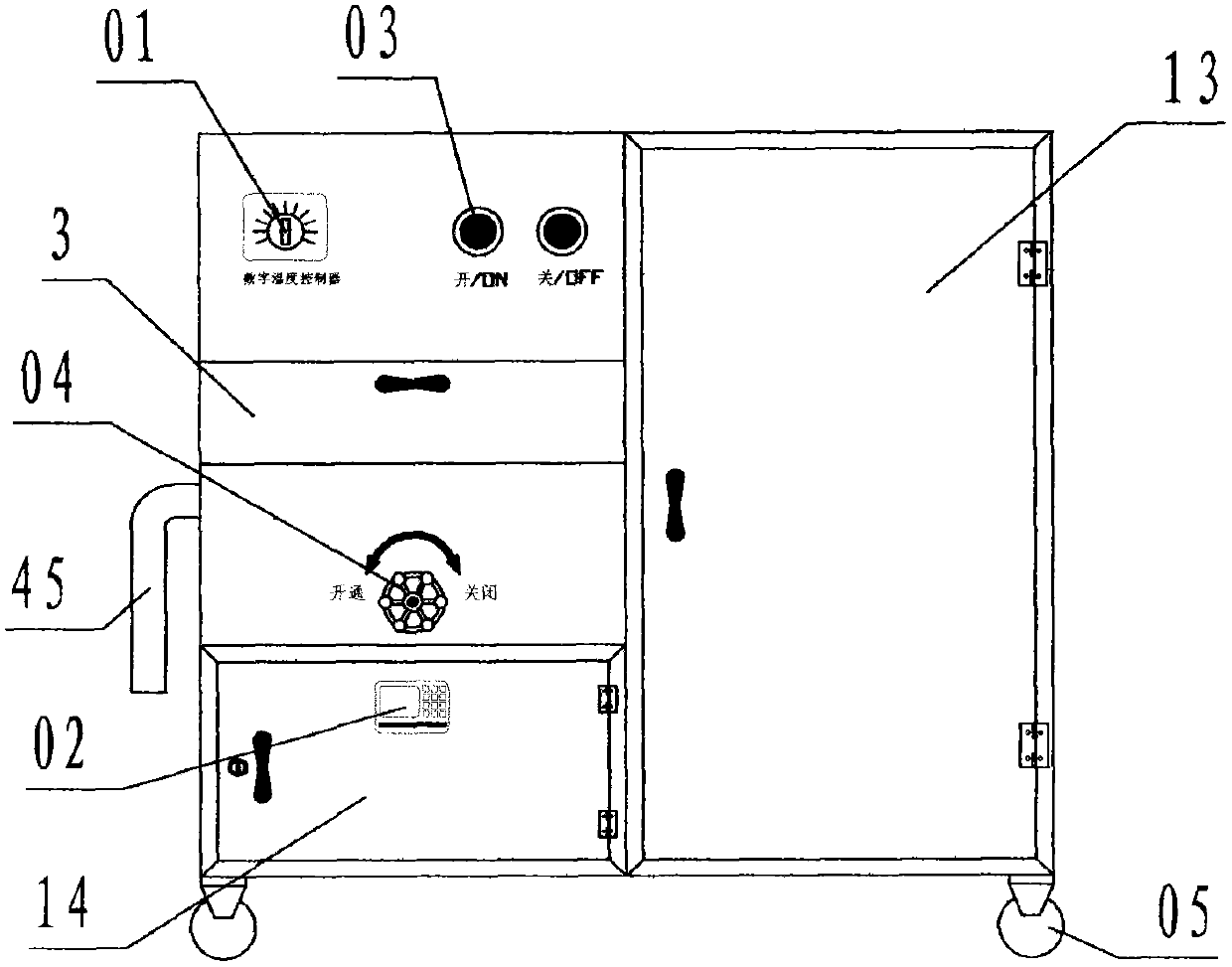

[0022] refer to figure 1 , figure 2 , a kitchen food waste disposal machine for automatic separation of oil and water residues of the present invention, comprising a housing 1, a slag-liquid separator 2, a water tray drawer 3, an oil-water separation box 4, an oil storage tank 5, and a dry material box 6, wherein: The housing 1 is hollow and thin-walled, with angle steel brackets inside, and a rectangular stainless steel shell. The middle part of the housing 1 is provided with a stainless steel plate-shaped partition wall in the up and down direction; 1. The inner chamber is divided into two left and right chambers, which are respectively called the left chamber and the right chamber; the upper part of the left chamber of the housing 1 is provided with a circular through hole called the entrance, and the entrance is provided with a A grate composed of stainless steel pipes arranged at even intervals in the front and back directions, the grate and the entrance are collectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com