Device for preparing nanometer metal powder by continuous wire electric explosion

A nanometer metal powder and electric explosion device technology, which is applied in the field of continuous wire electric explosion preparation nanometer metal powder device, can solve the problems that the metal wire is not stable and reliable, hinders the continuous progress of the metal wire, reduces production efficiency, etc., and achieves low cost and high production efficiency. Simplicity and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

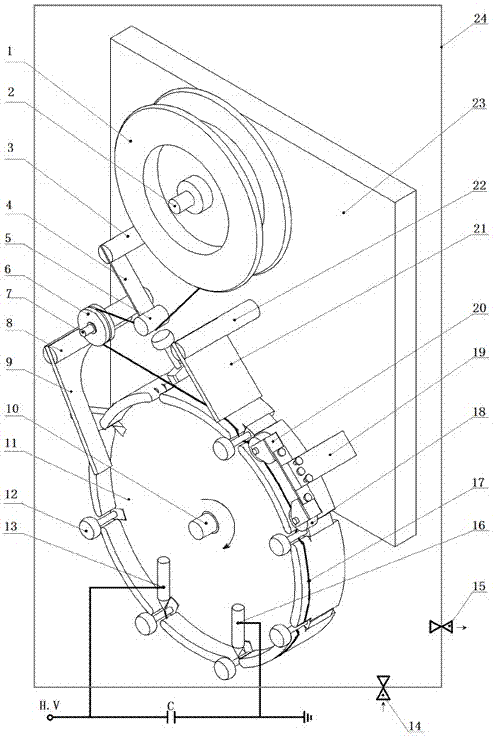

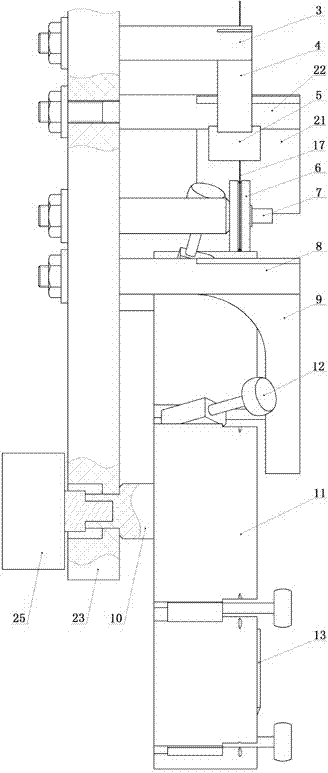

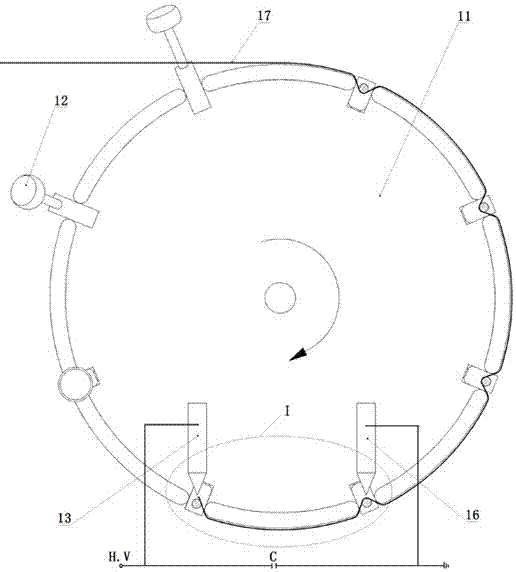

[0009] Such as Figure 1~5 As shown, the present invention is a device for preparing nanometer metal powder by continuous wire electric explosion, including an electric explosion chamber 24 and an electric explosion device, wherein the electric explosion device includes a driving mechanism, a pressure lifting rod mechanism, a wire feeding mechanism, an explosion mechanism, and an electric explosion chamber 24 It is equipped with an inlet valve 14 and an outlet valve 15. The electric explosion device is installed in the electric explosion chamber 24. The electric motor 25 drives the wheel disc 11 to rotate, and the metal wire 17 is fixed on the wheel disc 11 by the pressure lifting rod mechanism. Continuously fed by the wire feeding mechanism, the two poles of the energy storage capacitor C are connected to the high voltage generator H.V, the high voltage electrode 13 is connected to the high voltage end of the energy storage capacitor C, and the low voltage electrode 16 is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com