Integrated 3D (three-dimensional) printer extruding nozzle

A technology of 3D printers and nozzles, which is applied in the field of 3D printing, can solve the problems of increasing the cost of 3D printers due to the structure of extrusion nozzles, the influence of 3D printing control accuracy, and the attenuation of temperature measurement signals, and achieves low cost of use and maintenance, simple structure, and reduced The effect of signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to understand the technical content of the present invention more clearly, the following embodiments are given for detailed description.

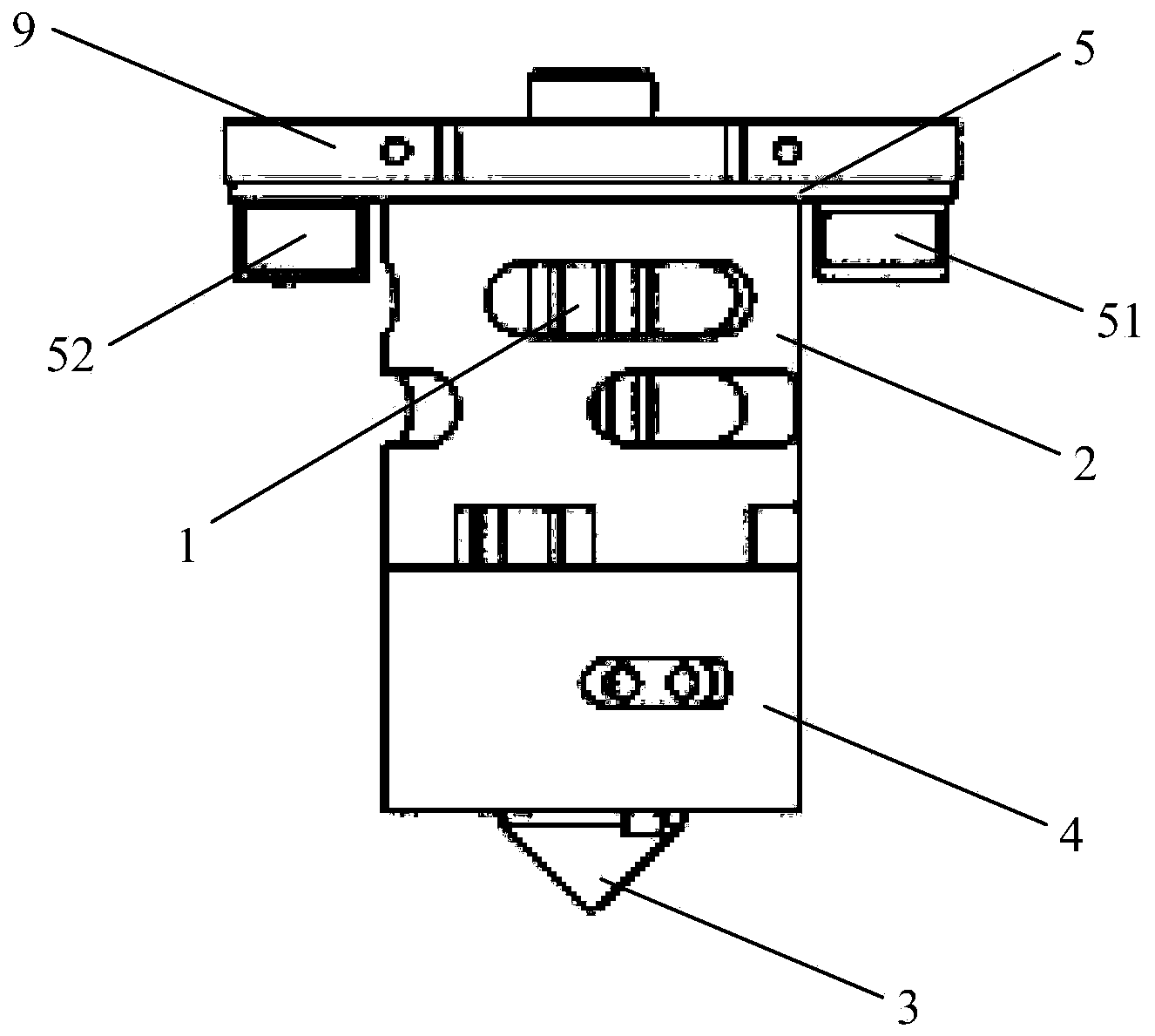

[0022] see figure 1 As shown, it is a schematic structural diagram of the extrusion nozzle of the integrated 3D printer of the present invention.

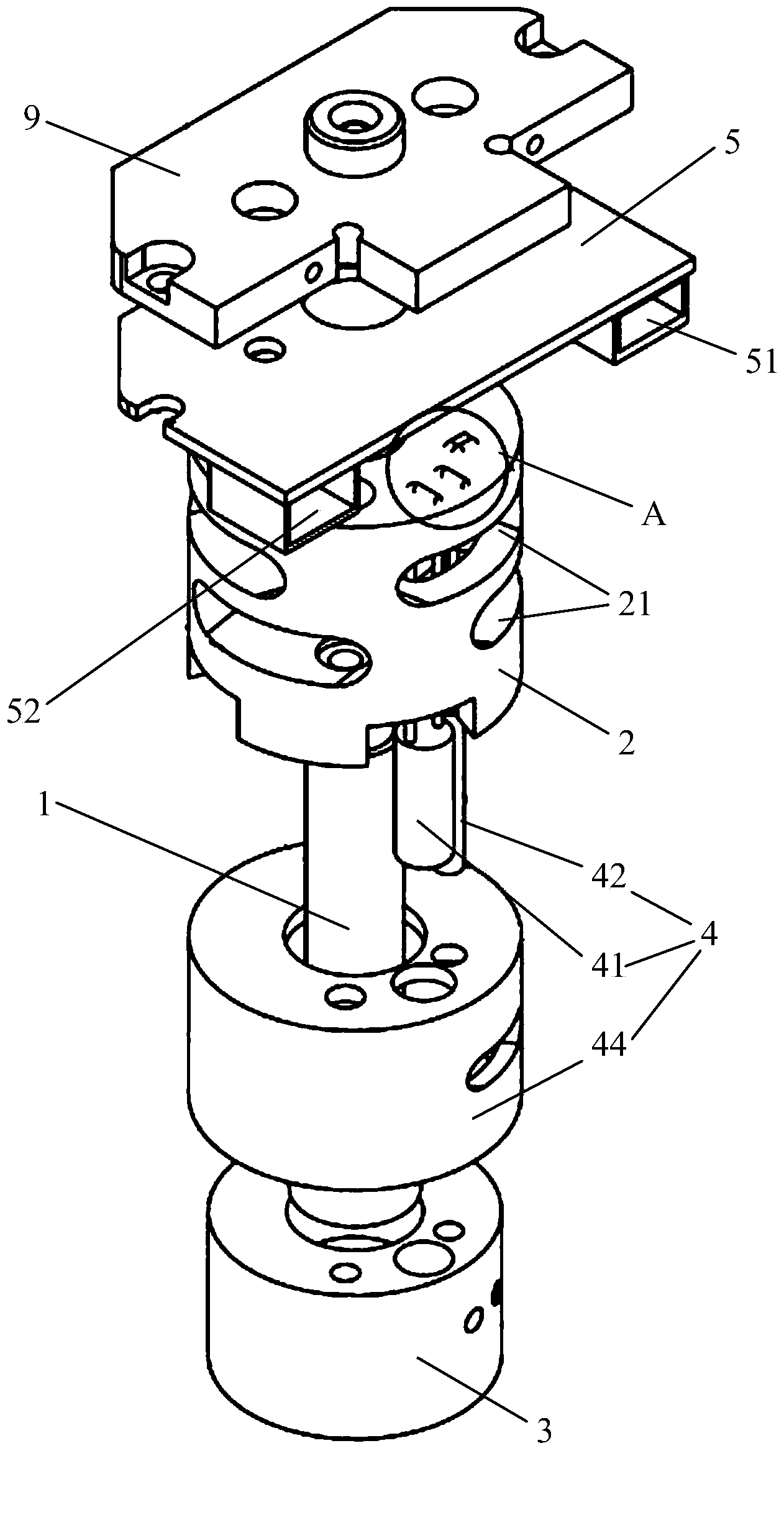

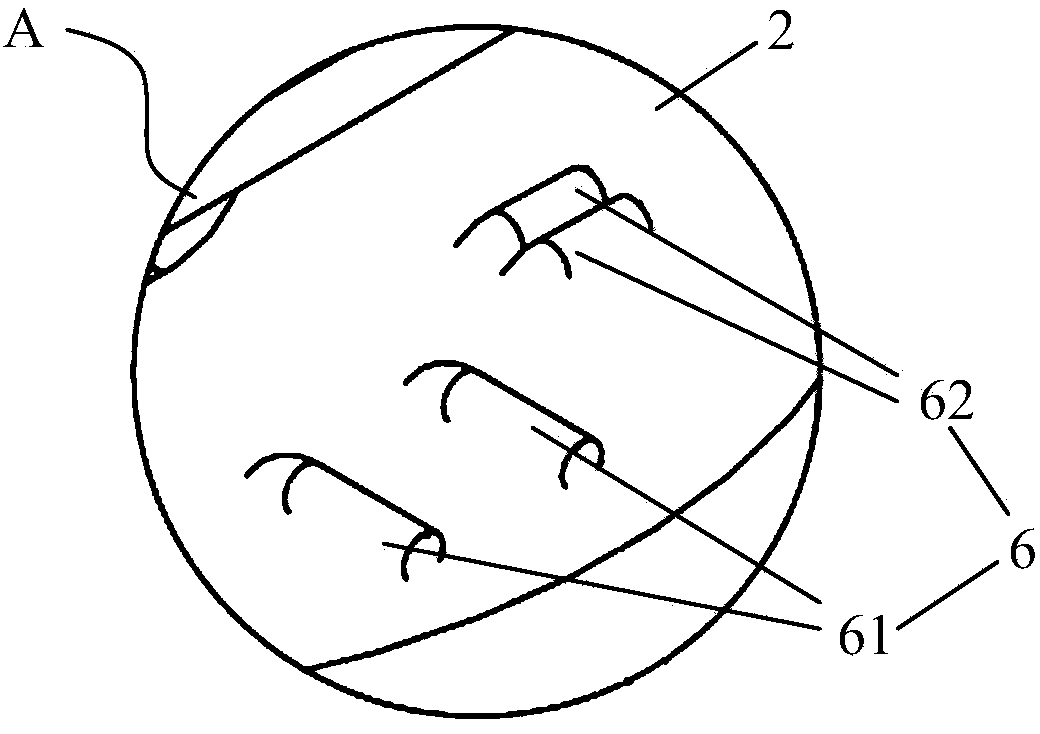

[0023] In one embodiment, as figure 1 and figure 2 As shown, the extrusion nozzle of the integrated 3D printer includes an extrusion material tube 1 , a fixing bracket 2 , an extrusion head 3 , a heating module 4 and a printed circuit board 5 . Wherein, the fixing bracket 2 is sleeved and fixed on the outer side of the extrusion material pipe 1; the extrusion head 3 is fixed at the bottom end of the extrusion material pipe 1 and communicated with the extrusion material pipe 1; the heating module 4 is sleeved on the outside of the extruding material tube 1, and is located between the bottom end of the fixing bracket 2 and the top end of the extrusion head 3, and the top end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com