Planetary type dual-mode petrol-electric parallel-serial hybrid power system

A hybrid system and planetary technology, applied in the field of power system, can solve problems such as incomplete realization of parallel mode, high motor dependence, and insufficient optimization of transmission efficiency, so as to improve fuel economy, reduce maintenance, and improve vehicle fuel consumption Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

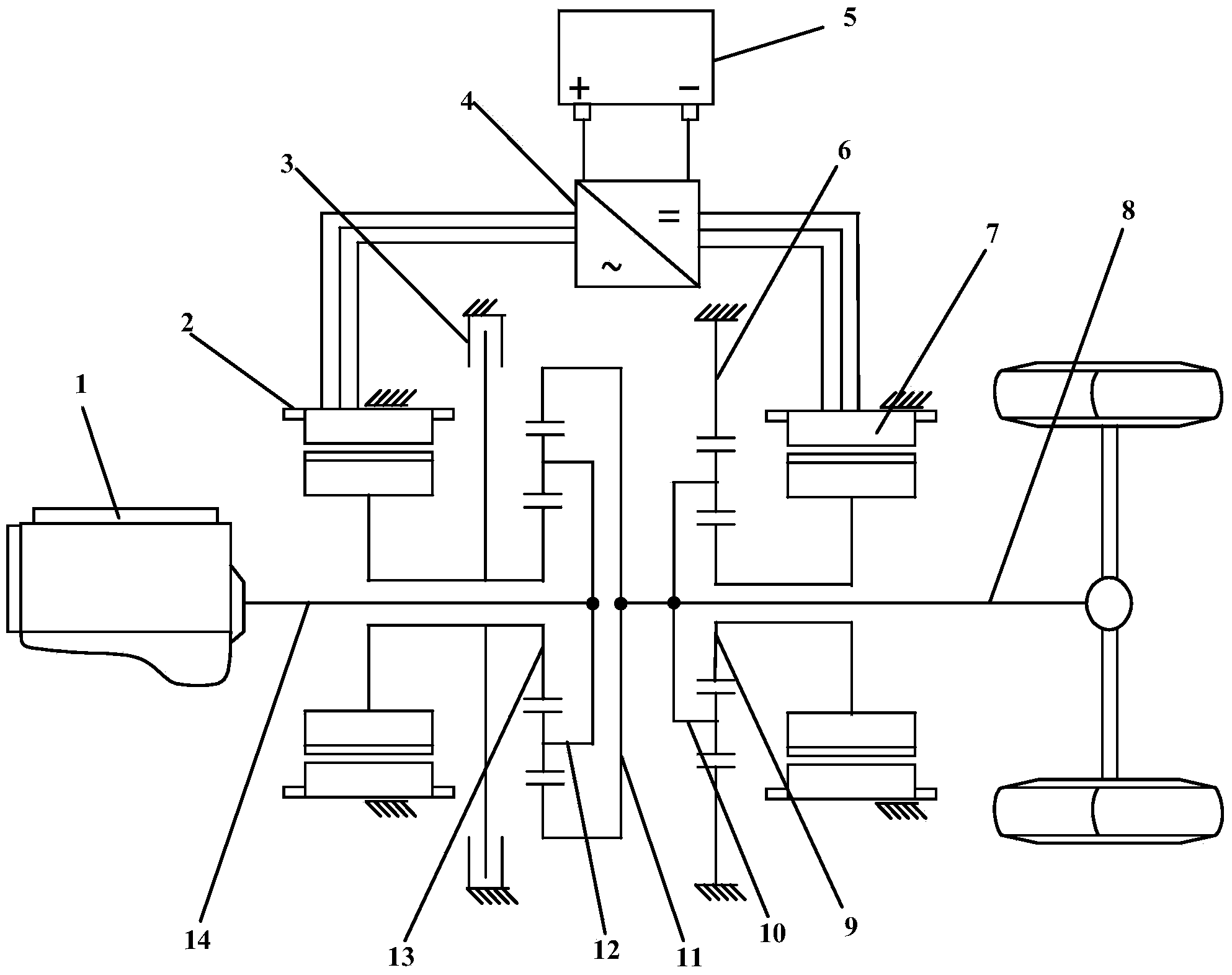

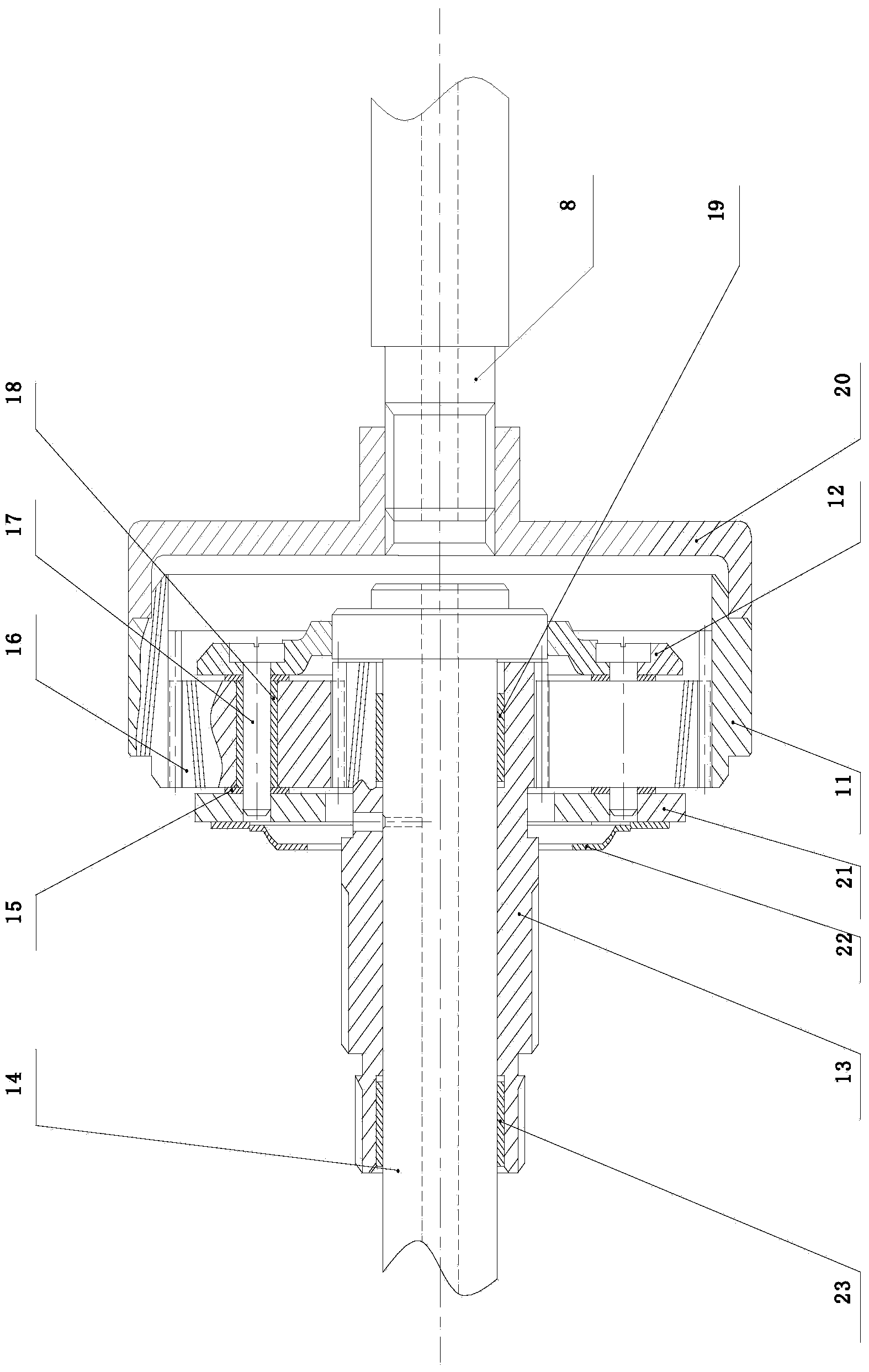

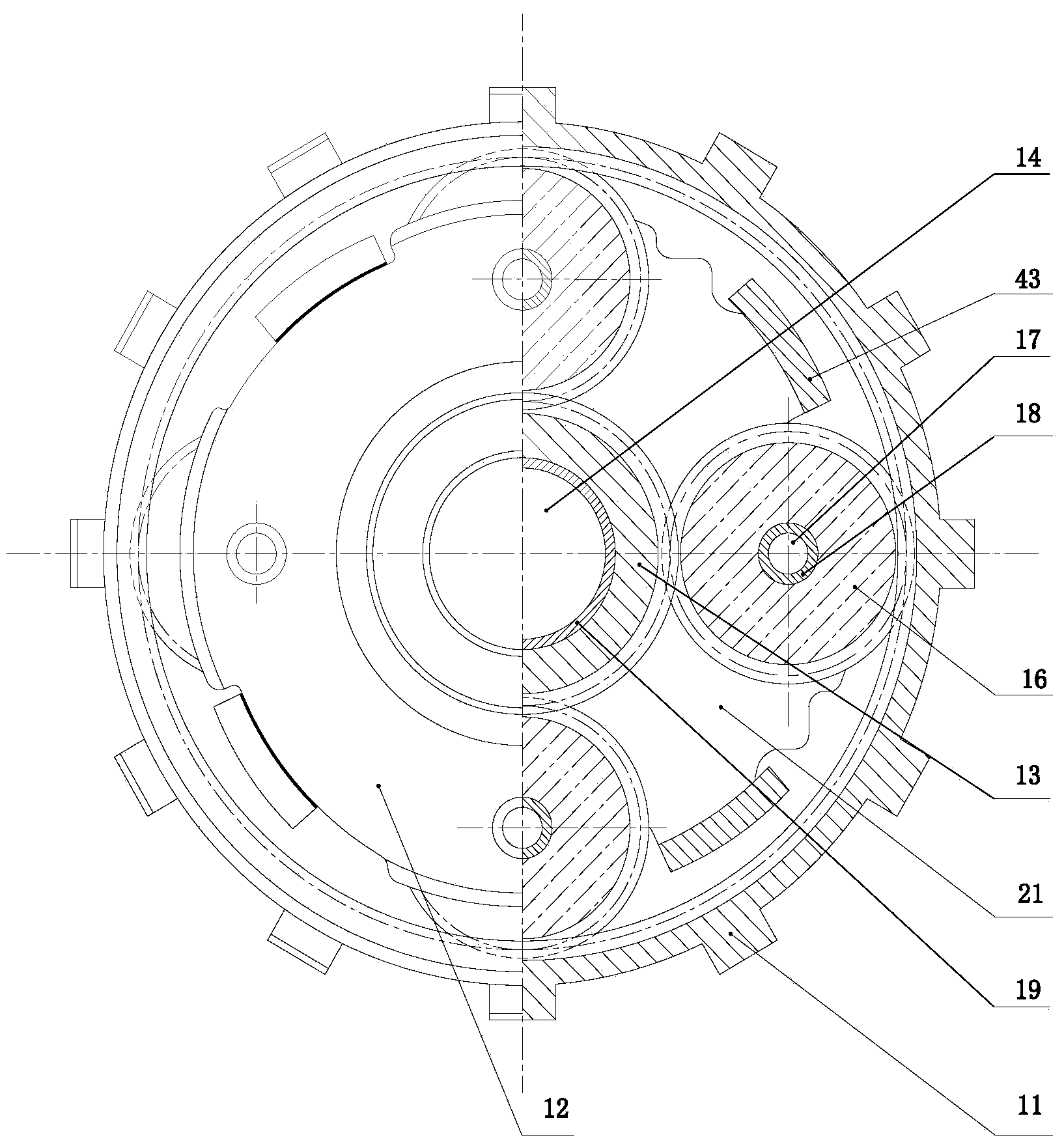

[0035] The purpose of the present invention is to provide a new type of hybrid power system, that is, to provide a hybrid power system with double planetary row as the electromechanical coupling device, so as to realize the electronic integration of the hybrid power system. The continuously variable speed function controls the engine to work in the best fuel economy zone, improves the fuel economy of the vehicle, and achieves ultra-low emissions. At the same time, it overcomes the current heavy dependence of the hybrid electric vehicle on the motor, which requires a large motor to provide sufficient driving force In addition, the planetary dual-mode oil-electric hybrid system described in the present invention can fully realize the parallel mode due to the addition of the clutch, and obtain more optimized comprehensive transmission efficiency and vehicle fuel economy.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com