Safe discharge method of new-energy vehicle capacitor electricity

A new energy vehicle, safe discharge technology, applied in electric vehicles, electrical devices, vehicle components, etc., can solve problems such as discharge capacitors, and achieve the effect of improving safety and shortening discharge time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

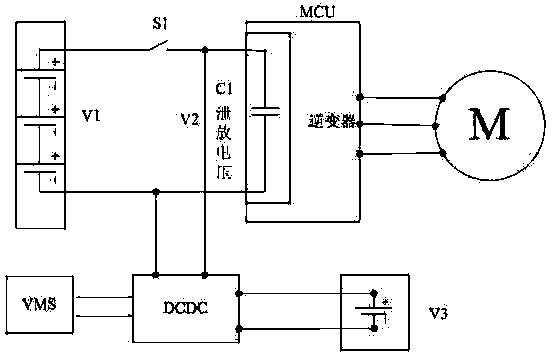

[0020] Such as figure 1 When the vehicle is running normally, the relay S1 is in the closed state, and the battery provides the voltage V1 required by the MCU (motor control unit) to drive the motor. When the VMS (vehicle management system) detects that the battery voltage V3 is less than 13.8V, The DC / DC is enabled to charge the battery, and the DC / DC input is connected to the MCU bus terminal. The input voltage is equal to the battery voltage V1 and the MCU bus voltage V2, that is, V1=V2.

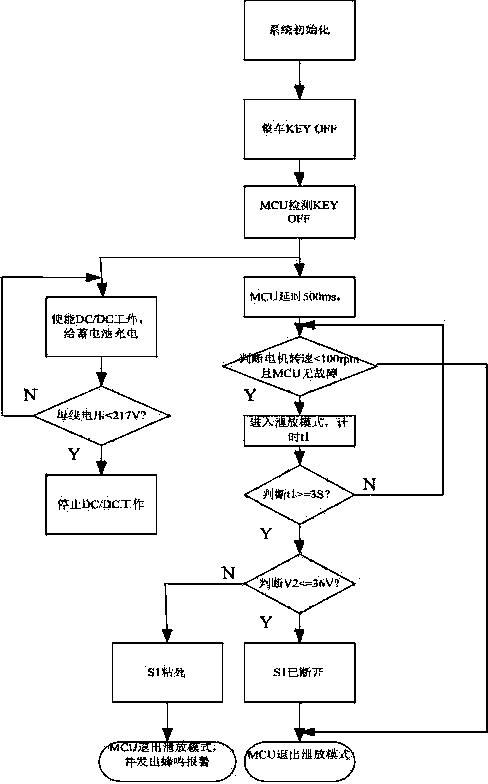

[0021] When the vehicle KEY is OFF (the key is turned off), MCU and VMS detect KEY OFF and delay 500ms, relay S1 is disconnected, and the actual time required for relay S1 to disconnect is within 500ms, so MCU and VMS must delay 500ms to determine that the relay is completely Discharge the capacitor C1 after disconnection to avoid the phenomenon that S1 sticks to death due to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com