Method and device for improving cruising ability of automatic navigation trolley

A technology of automatic navigation car and automatic charging device, which is applied in the direction of electric vehicles, electric/hybrid power, electric traction, etc., can solve the problems of inconvenient use, reduced work efficiency, and increased unloading process, so as to achieve convenient installation and use, The effect of improving production efficiency and optimizing layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

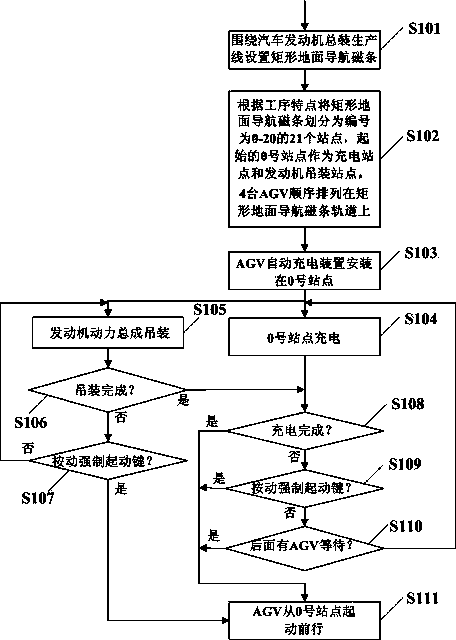

[0037] Example 1: figure 1 Shown is a flow chart of the present invention. In the present embodiment, there are 21 stations and 4 AGVs, and the basic steps are:

[0038] S101: Set up a rectangular ground navigation magnetic strip around the automobile engine powertrain assembly line as a closed running track for the AGV;

[0039] S102: Divide the rectangular ground navigation magnetic strip into 21 stations numbered 0-20 according to the characteristics of the process. The initial station No. 0 is used as the charging station and engine powertrain hoisting station. Four AGVs are arranged in sequence on the rectangular ground navigation magnetic strip. on the track;

[0040] S103: The AGV automatic charging device is installed at station 0, and automatically charges the loaded battery pack when the AGV enters station 0;

[0041] S104: start charging at station 0;

[0042] S105: The hoisting of the engine powertrain starts;

[0043] S106: Judging whether the hoisting of the e...

Embodiment 2

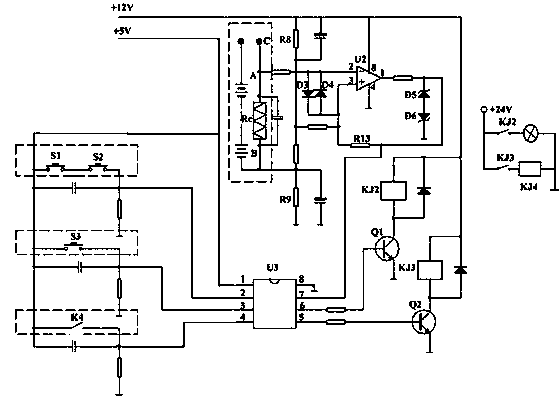

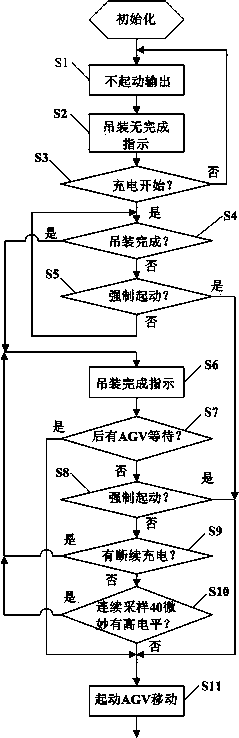

[0049] Embodiment 2: as figure 2 As shown, it is a device to improve the battery life of the automatic navigation car, and the automatic charging device is installed at station 0. The controller adopts single-chip microcomputer.

[0050] There are 4 AGVs on the production line; rectangular ground navigation magnetic strips are installed on the production line, and are divided into 21 stations (0-20); the four AGVs automatically walk along the ground rectangular navigation magnetic strips, automatically stop, and The stations are charged sequentially.

[0051] The AGV enters station 0 for charging, and at the same time, the operator hangs the engine power assembly through the electric hoist and drops it onto the fixture tray on the AGV trolley.

[0052] When the AGV is not charging (that is, under normal working conditions), the direction of the current flowing through the sampling resistor RC is from A to B, that is, the voltage is A positive and B negative; when the AGV is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com