Method and system for recycling ethylene in tail gas through barren liquor effect in demethanization process

A technology of lean liquid effect and demethanization stripping tower, which is applied in the field of ethylene recovery in tail gas, can solve the problems of limited promotion, high investment, and insignificant energy saving effect, and achieve the effect of low investment, low energy consumption and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are examples and process parameters thereof, but the content of the present invention is not limited to the scope of these examples.

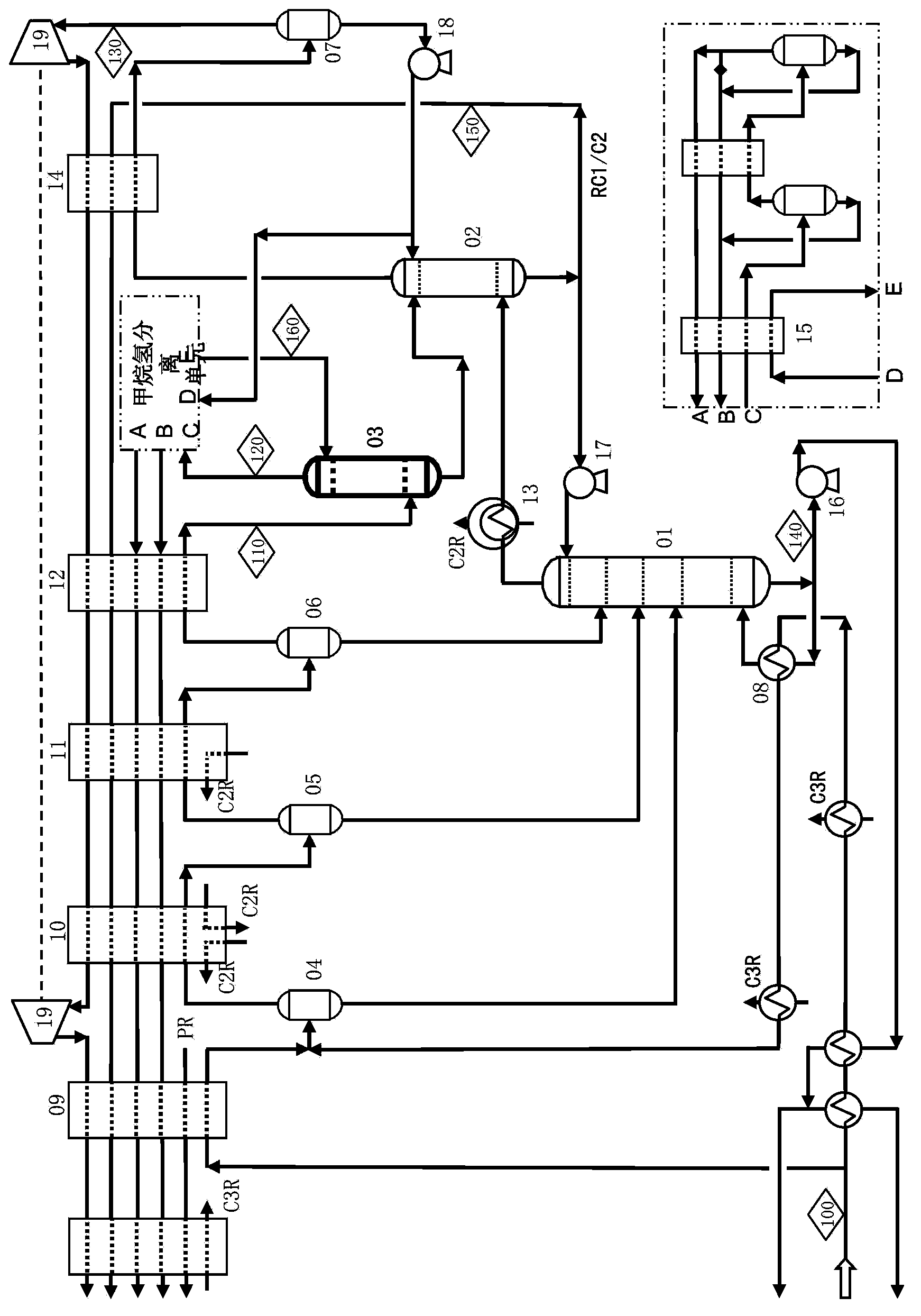

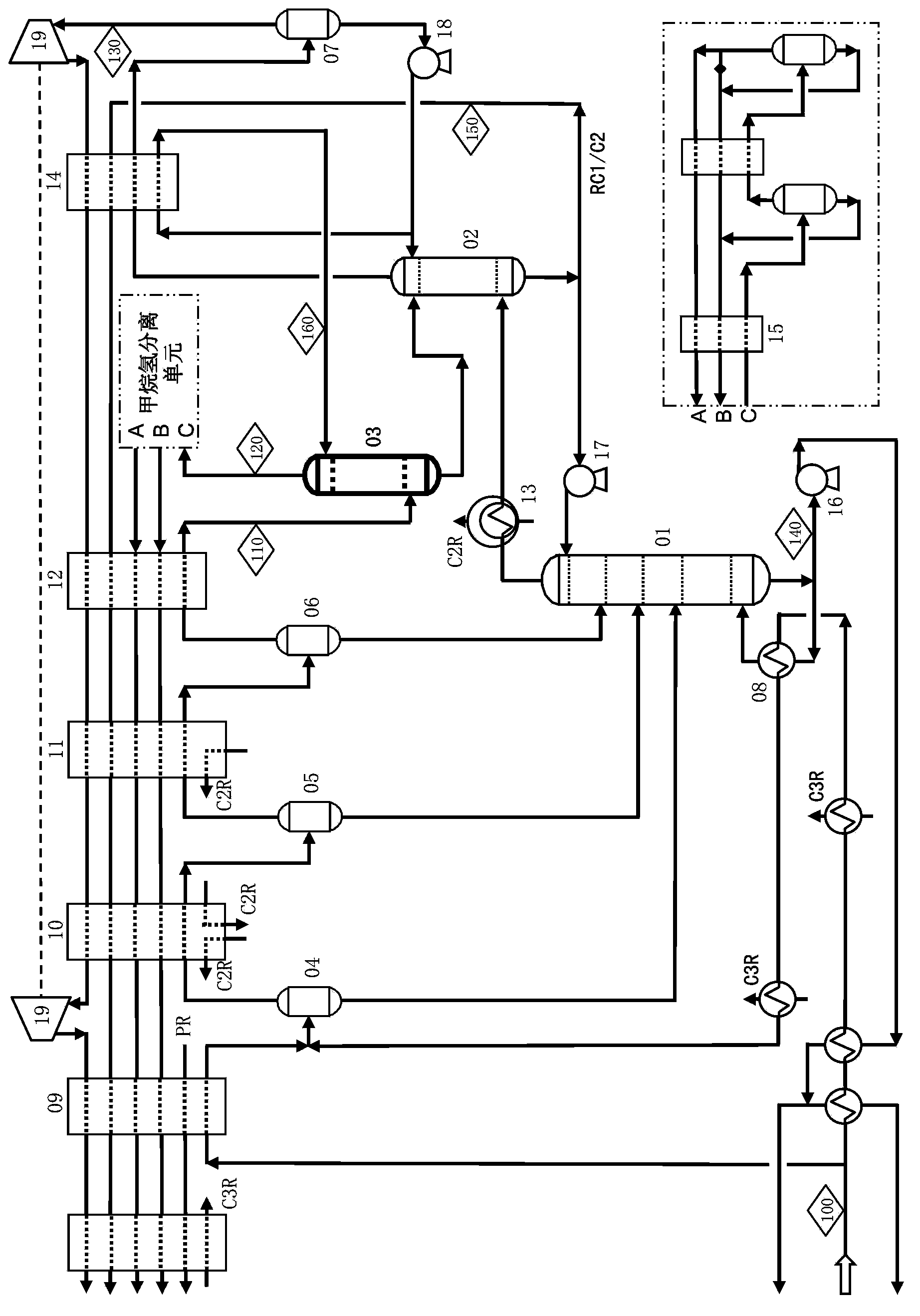

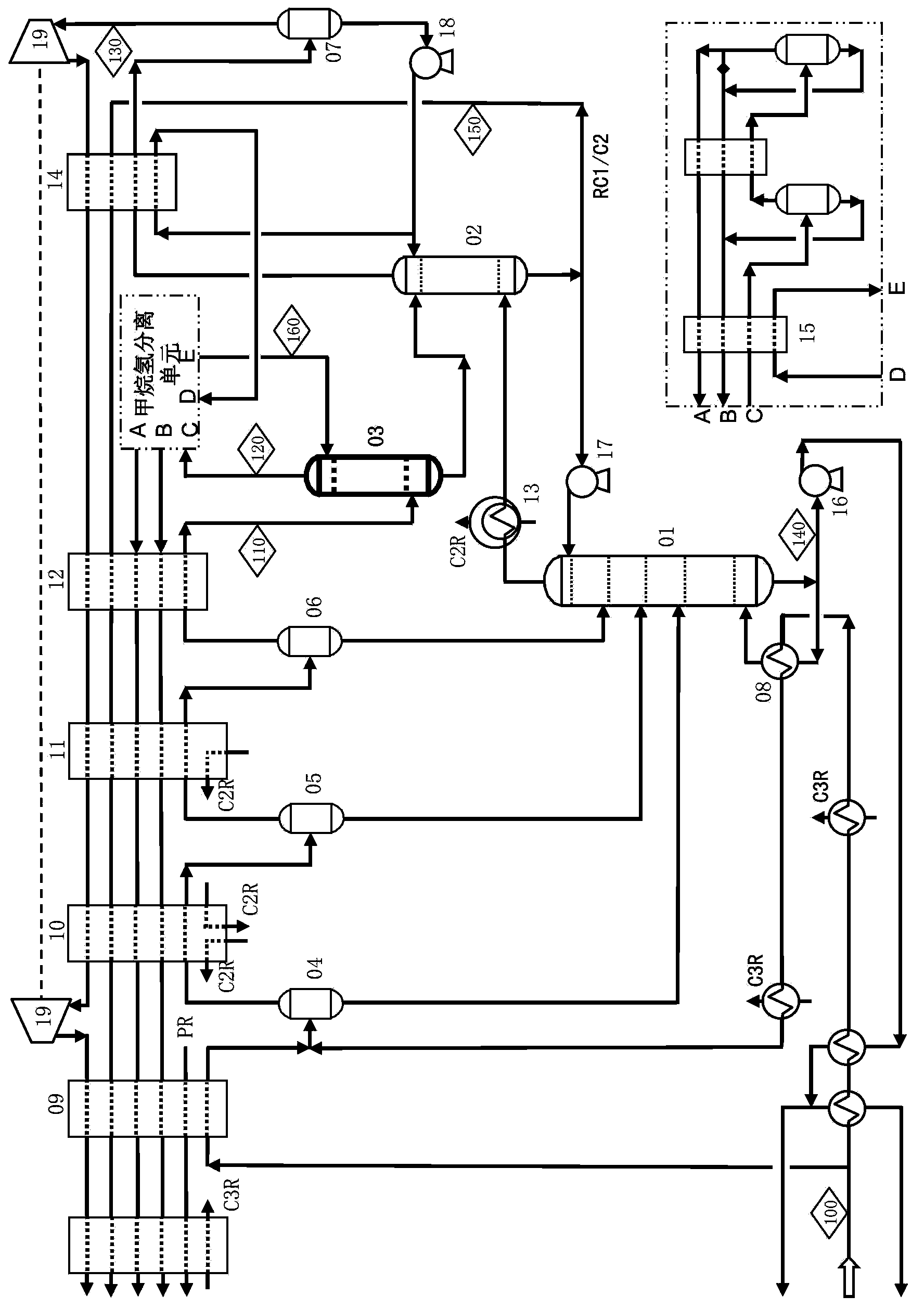

[0040] Such as figure 1 As shown, the primary deep subcooling scheme of the absorbent of the present invention includes a demethanizer stripping tower 01, a demethanizer rectifying tower 02, and a carbon dioxide absorbing tower 03 (with trays or fillers equivalent to about 6 to 7 plates inside). ), first demethanizer feed separation tank 04, second demethanizer feed separation tank 05, third demethanizer feed separation tank 06, demethanizer reflux tank 07, demethanizer stripper reboiler 08. No. 1 demethanizer feed heat exchanger 09, No. 2 demethanizer feed heat exchanger 10, No. 3 demethanizer feed heat exchanger 11, No. 4 demethanizer feed heat exchanger 12, Demethanizer stripping tower overhead cooler 13, demethanizer rectifying tower condenser 14, methane hydrogen heat exchanger (outside the system) 15, demethanizer st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com