Heat-resistant salt-tolerant water-soluble amphiphilic polymer composite thick oil viscosity reducer

A technology of amphiphilic polymer and heavy oil viscosity reducer, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve the problems of low concentration, poor temperature and salt resistance, and low viscosity reduction rate of medium and high viscosity heavy oil and other problems, to achieve the effect of highlighting technological progress and solving poor temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

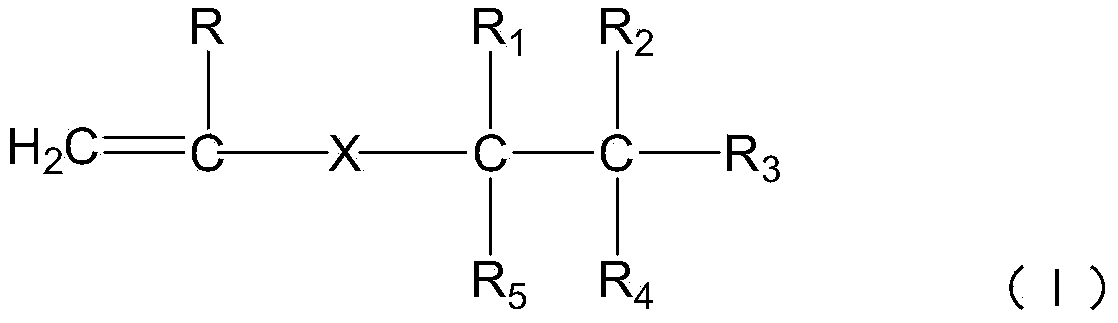

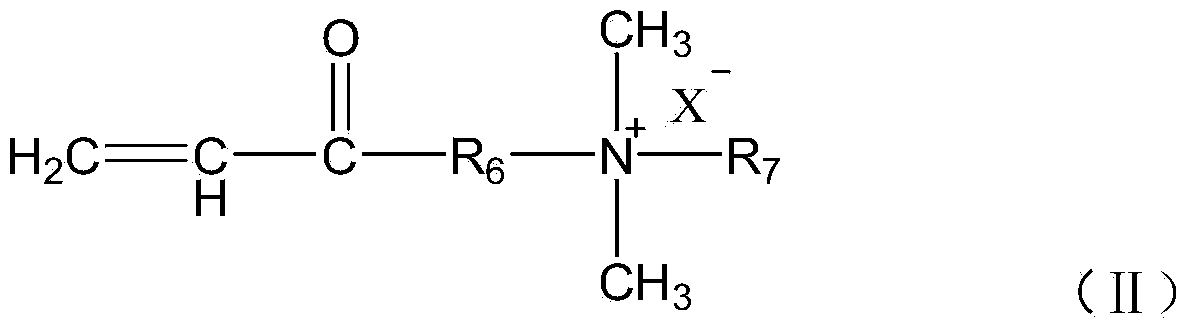

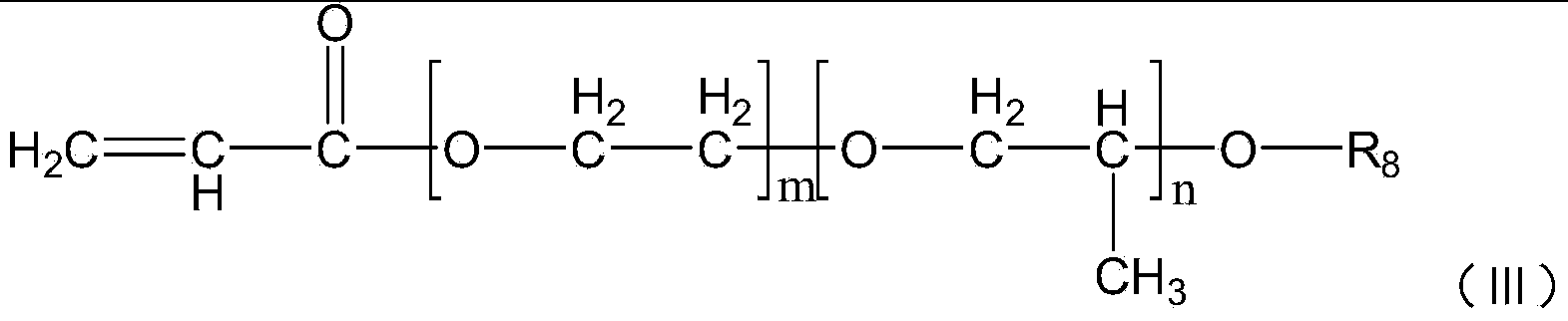

[0034] 1) Component A of the present invention is formed by quaternary copolymerization of acrylamide, hydrophobic alkylacrylamide, acrylamidoalkyl ammonium chloride quaternary ammonium salt and nonionic polyether acrylate:

[0035] The monomer acrylamido alkyl ammonium chloride quaternary ammonium salt (II) in the amphiphilic polymer of the above component A is self-made;

[0036] Preparation method: Dimethyl alkylacrylamide and halogenated alkanes are dissolved in acetone with a mass ratio of 0.6 times the reaction material in turn according to the molar ratio of 1:1, and stirred and reacted for 50 hours at 45°C until the quaternary ammonium salt reaction is complete , the product uses a filter belt to centrifuge to remove the solvent and then dry it.

[0037] The monomer nonionic polyether acrylate (Ⅲ) in the amphiphilic polymer of the above component A is self-made;

[0038] Preparation method: acrylic acid and alkyl polyoxypropylene polyoxyethylene ether are dissolved in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com