440MPa of precipitation strengthening-type cold rolled interstitial free (IF) steel containing niobium and production method thereof

A precipitation-strengthening, high-strength technology, applied in 440MPa niobium-containing precipitation-strengthening cold-rolled IF steel and its production field, can solve the problems of long annealing time and inferior performance to continuous annealing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

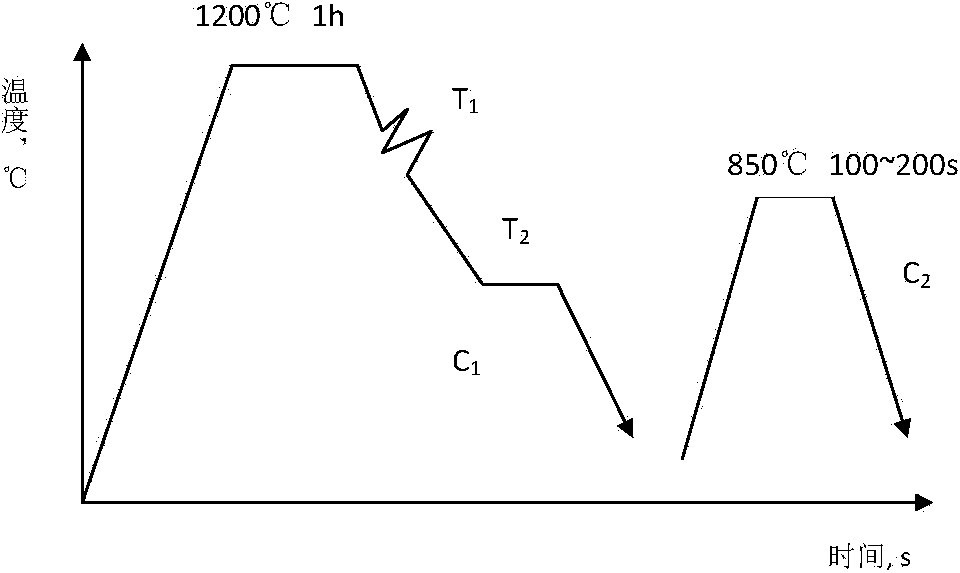

[0024] Below in conjunction with accompanying drawing, describe the present invention in detail with small-scale test embodiment.

[0025] As shown in Figure 1, a 440MPa niobium-containing precipitation-strengthened cold-rolled IF steel and its production method, the steel ingot is smelted in a 50kg vacuum induction heating furnace, and the chemical composition weight percentage is: C: 0.006%, Si: 0.05%, Mn: 1.8%, P<0.04%, S<0.004%, N≤0.003%, Nb: 0.11%, B: 0.001%, Ti: 0.02%, and the rest are Fe and unavoidable impurities. The hot rolling is completed on the 450 rolling mill in the laboratory. The rolling process is as follows: the steel ingot is heated to 1200-1250 ° C, and the rolling starts after holding the heat for 1 hour. The final rolling temperature is 900 ° C to ensure rolling in the austenite zone. 35mm is hot rolled into 4mm, the coiling temperature is 630°C, and it is cooled with the furnace. The cold rolling reduction is 85%, the annealing temperature is 850°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com