Completely-forming computerized flat knitter compound needle

A computerized flat knitting machine and fully formed technology, which is applied in knitting, textiles and papermaking, etc., can solve problems such as loop transfer and knitting instability, loop transfer and overall knitting work cannot be normal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

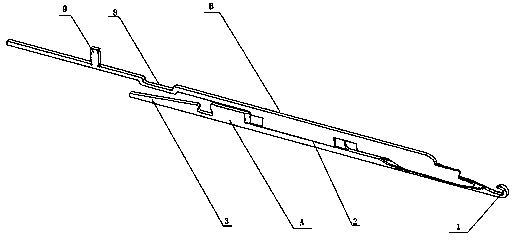

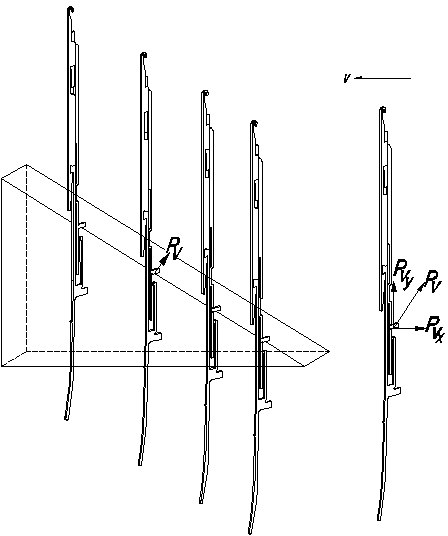

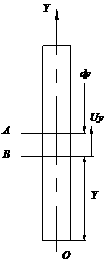

[0119] see figure 1 and attached Figure 4-6 , the present invention is applied to a compound needle of a fully-shaped computerized flat knitting machine, including a needle bar A and a needle core B, the needle bar A consists of a needle hook 1, a connecting part 2 and a needle tail 3 in turn, a needle hook 1, a connecting part 2 and a needle The tail 3 is made in one piece, the needle tail 3 is provided with a guide groove 4, and the needle bar A is connected to the bottom needle through the guide groove 4; A needle butt 9 is arranged at the tail of the needle butt 9, and a U-shaped groove 8 is arranged on the core body 7 between the needle butt 9 and the sliding part 6; The needle core B can slide in the connecting part 2 of the needle bar A through the sliding part 6, the needle hook 1 is located at one end of the loop transfer part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com