Wellhead descending tool

A wellhead head and tool technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as collision and friction, low reliability, and many parts, achieve quick installation and release, save installation time, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

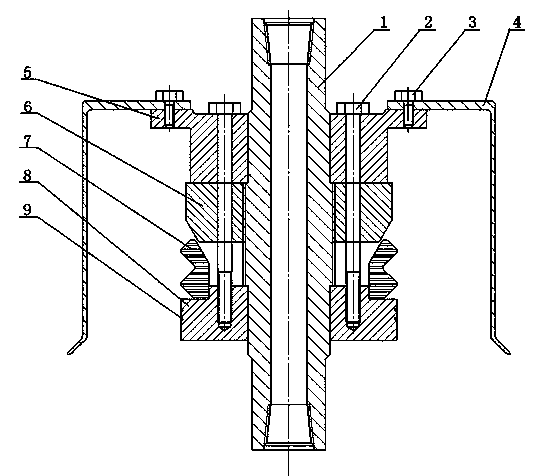

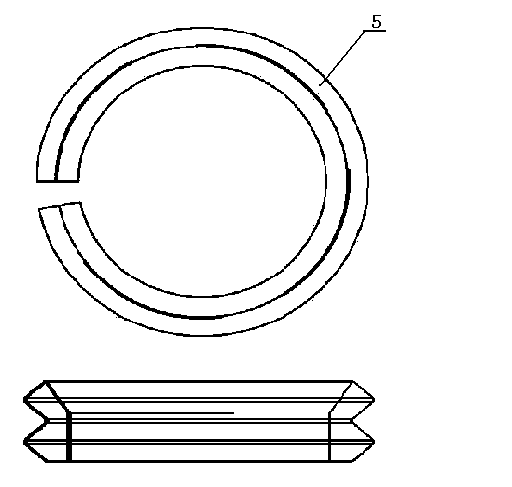

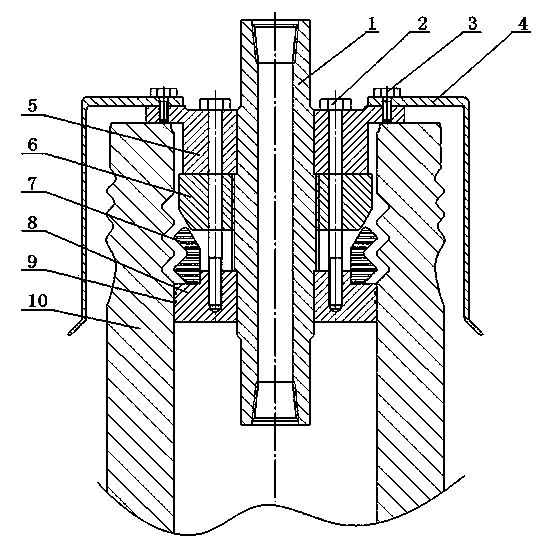

[0017] refer to figure 2 , The wellhead head lowering tool of the present invention includes a mandrel 1, a long bolt 2, a short bolt 3, a protective cover 4, an upper support block 5, a drive block 6, an open elastic locking ring 7 and a lower support block 8.

[0018] The well head lowering tool mandrel 1 is a stepped shaft, and there are threads at the middle step shaft to be connected with the driving block. The two ends of the stepped shaft where the threads are located naturally form baffles to locate the positions of the upper support block 5 and the lower support block 8 . There are tapered threads in the holes at the upper and lower ends of the mandrel 1, the upper thread is used for connecting drill pipes or other casings, and the lower thread is used for connecting other flushing tools. The drive block 6 is screwed onto the spindle 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com