Method and system for three-dimensional measurement of complex curved surface parts with multi-optical sensors

An optical sensor and complex surface technology, applied in the field of precision measurement, can solve the problems of difficult normal measurement, low measurement accuracy of special measuring tools, and inability to meet full inspection and full inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

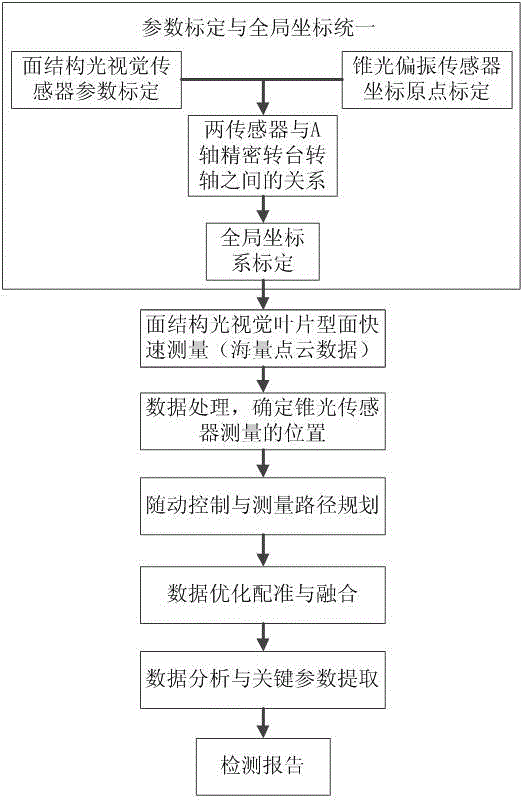

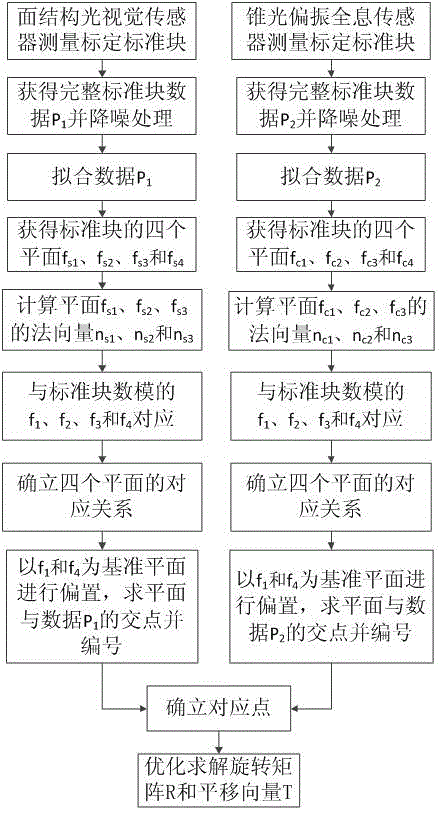

[0028] The working principle of the measurement method of the present invention is as follows: first, the global coordinate system calibration is carried out on the combined measuring head, so that the surface structured light visual sensor and the cone light polarization holographic sensor work in the same coordinate system; then the surface structured light in the combined optical measuring head is used to The visual sensor quickly measures the complex surface parts, obtains massive 3D point cloud data of the parts, processes the point cloud data, and determines the holes and discontinuous areas of the measurement data. The 4-axis control system drives the conoscopic polarization holographic sensor to move to the corresponding The position is precisely measured, and the complete point cloud data of the part is finally obtained. workflow such as figure 1 .

[0029] Measurement method provided by the invention comprises the steps:

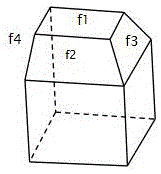

[0030] Step 1, calibrate the parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com