Method and device for detecting uniformity of optical glass based on white light interferometry

A technology of optical glass and white light interference, which is applied in the field of optical interferometry, can solve the problems of high manufacturing cost and high cost, and achieve the effect of reducing test cost, low environmental requirements, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

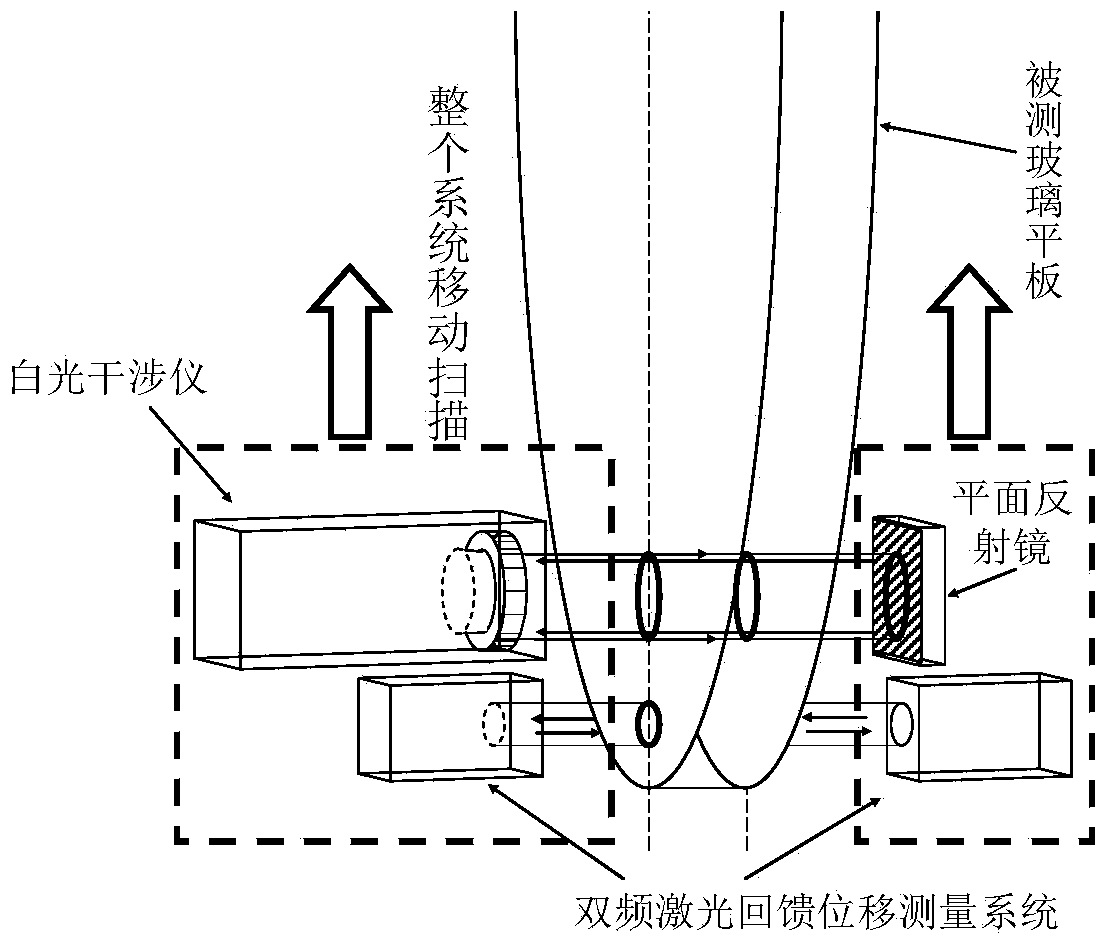

[0039] The present invention combines white light interferometry and displacement sensor measurement method for scanning detection figure 1 The method for the homogeneity of the glass plate, comprising the steps of:

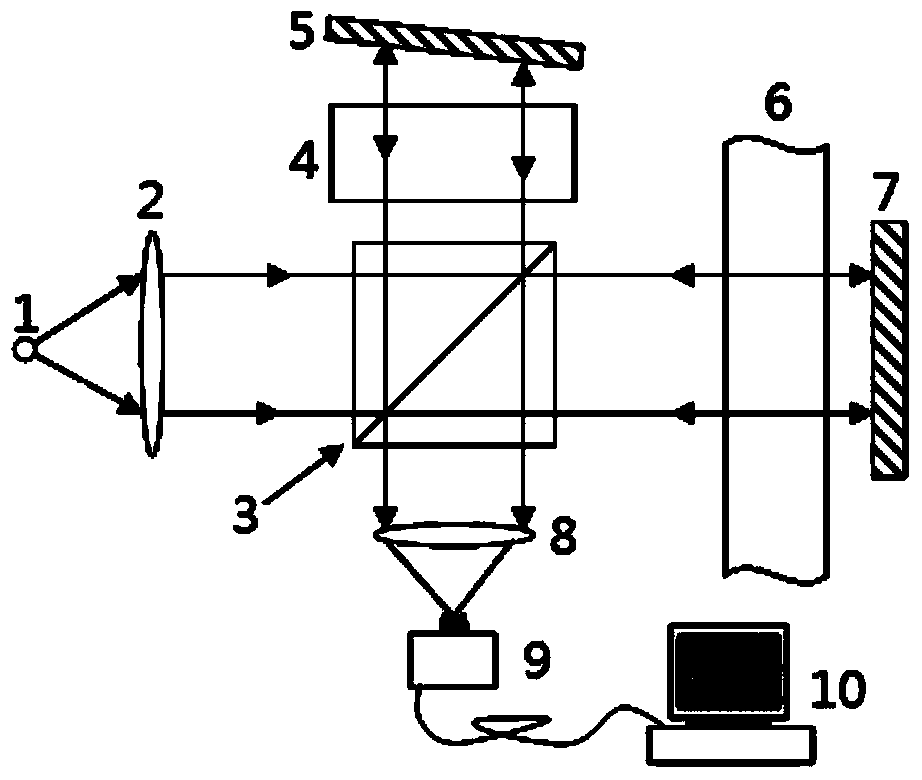

[0040] Step 1: First calibrate the white light interferometer. Each instrument according to figure 2 After being installed and adjusted in place as shown, a monochromatic LED is used as the light source of the interferometer, and its wavelength is λ, at figure 2 Put a standard compensation mirror into the position of the measured glass plate for calibration; Figure 5 As shown, adjust the front and rear positions of the standard compensation mirror and the first compensation mirror 4 in the optical path, so that the reflected light r 1 with r 2 ' / r 3 ’, r 2 with r 1 ' / r 2 ' / r 3 ’, r 3 with r 1 ' / r 2 ' / r 3 ’ the optical path difference is not zero, then r 1 with r 2 ' / r 3 ’, r 2 with r 1 ' / r 2 ' / r 3 ’, r 3 with r 1 ' / r 2 ' / r 3 ’ will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com