Transmission chain quality detection system based on machine vision

A transmission chain and machine vision technology, applied in instruments, measuring devices, optical testing flaws/defects, etc., can solve the problems of high labor intensity, inability to meet high-precision, high-efficiency testing requirements, time-consuming and labor-intensive, etc., to improve production. Efficient, easy to automate, easy to integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

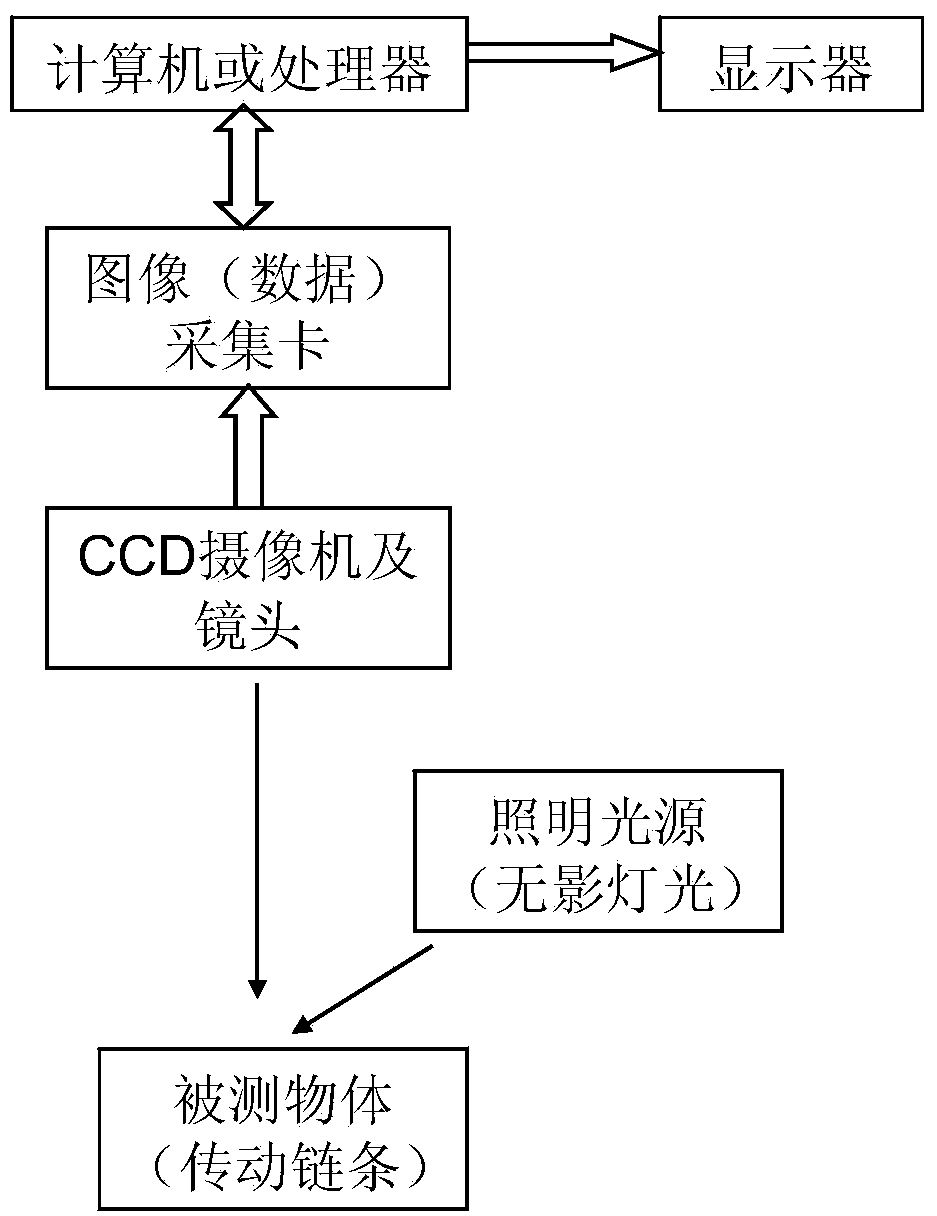

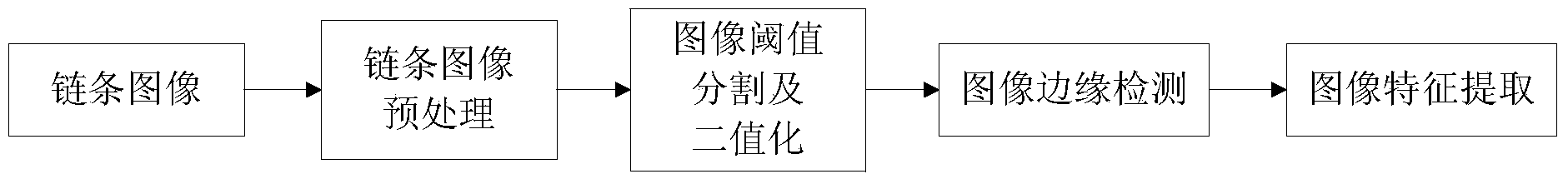

[0022] The system of the present invention is divided into two parts: hardware design and software design. The hardware design part mainly completes the ingestion and collection of chain images, and generally consists of lighting devices, cameras and image acquisition cards. The software part mainly includes preprocessing, threshold segmentation, binarization and other operations on the collected chain image to complete the feature extraction of the chain image. The implementation of the invention equipment in the factory requires a mainstream industrial control machine (configuration not lower than CPU main frequency 2.0G, memory 2G, hard disk 500G), an image acquisition card with a development kit, a uniform speed transmission belt 3 meters long, step The motor and gearbox ensure that the conveyor belt rotates at a constant speed. There are two rows of LED linear dot matrix light sources with a length of about 3 meters, distributed on both sides of the conveyor belt. Two CCD ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com