Infrared cut-off filter and lens module

An infrared cut-off and filter technology, applied in the field of optical components, can solve the problems of deteriorating the imaging quality of the imaging system, and achieve the effect of preventing the imaging quality and improving the reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

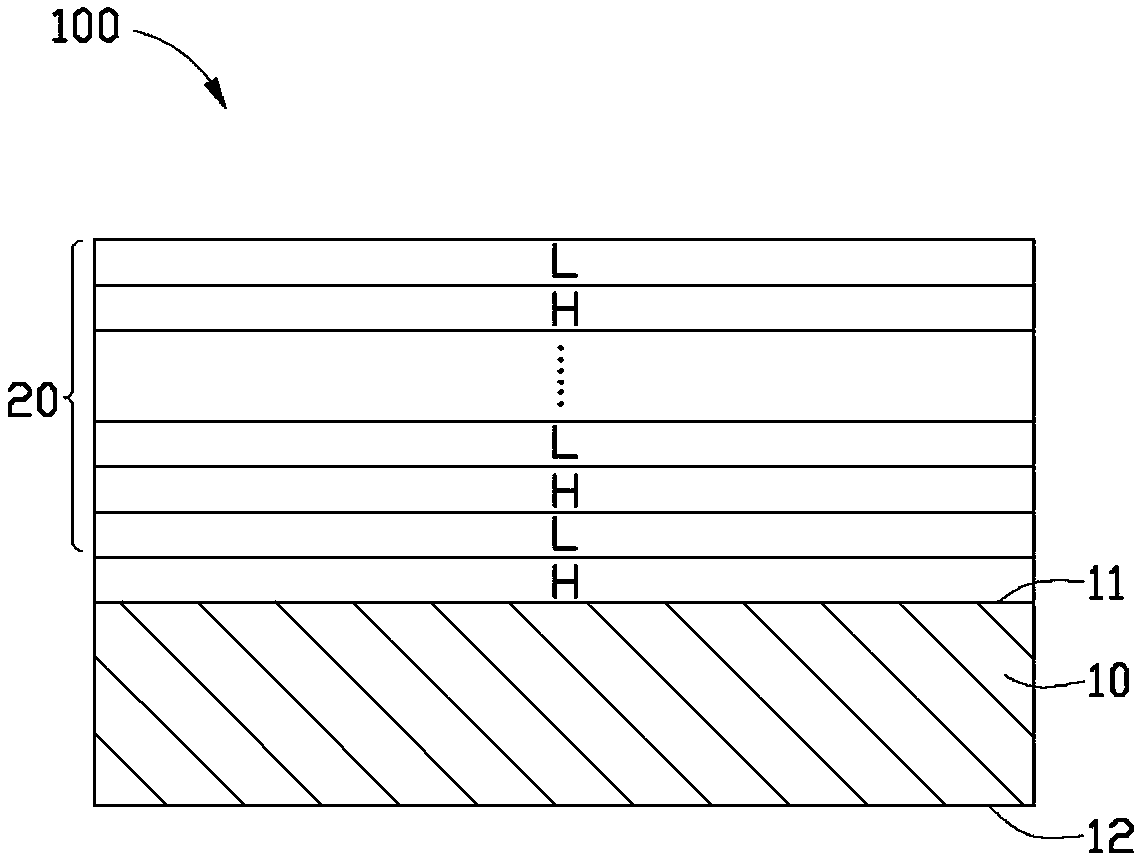

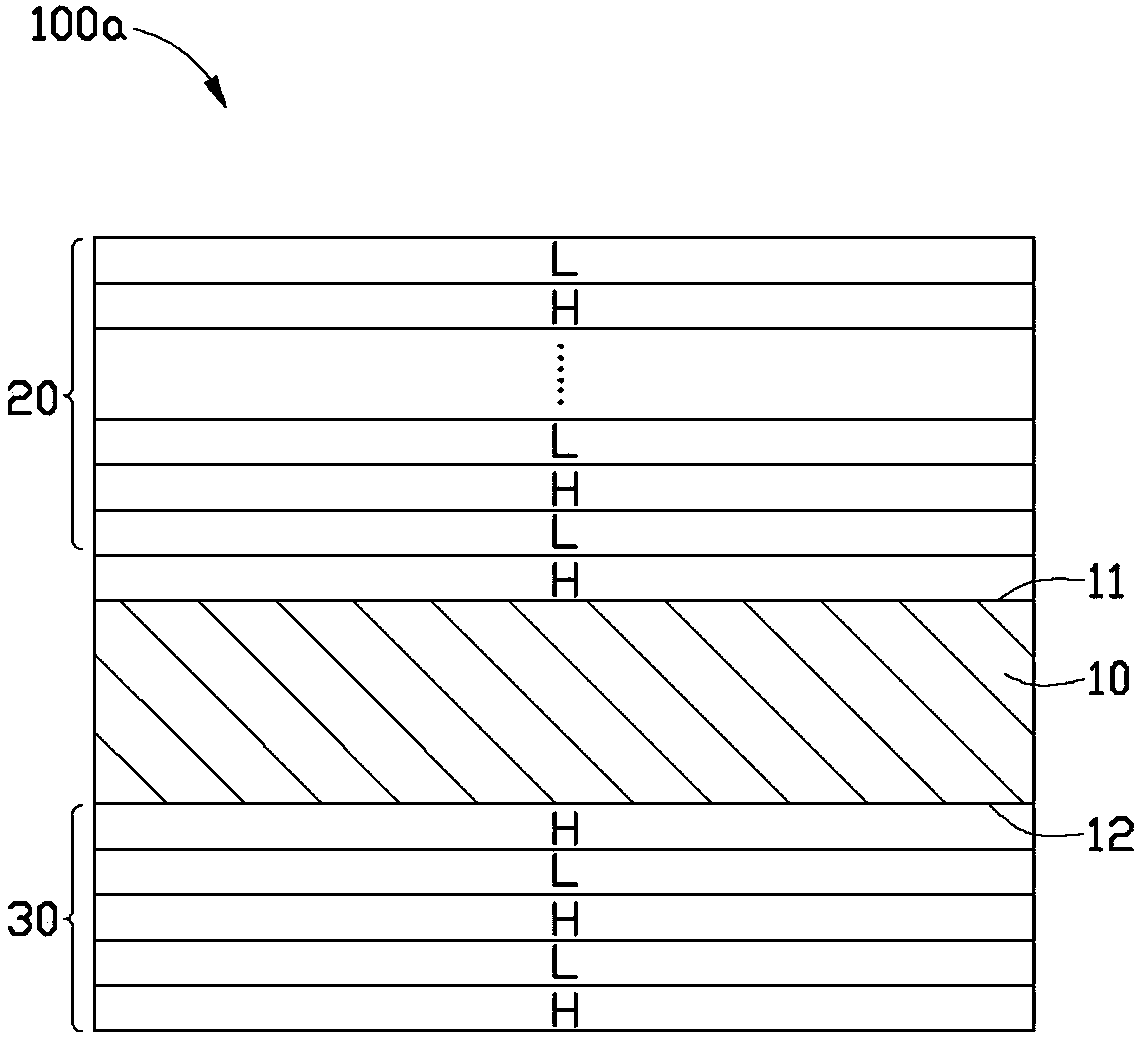

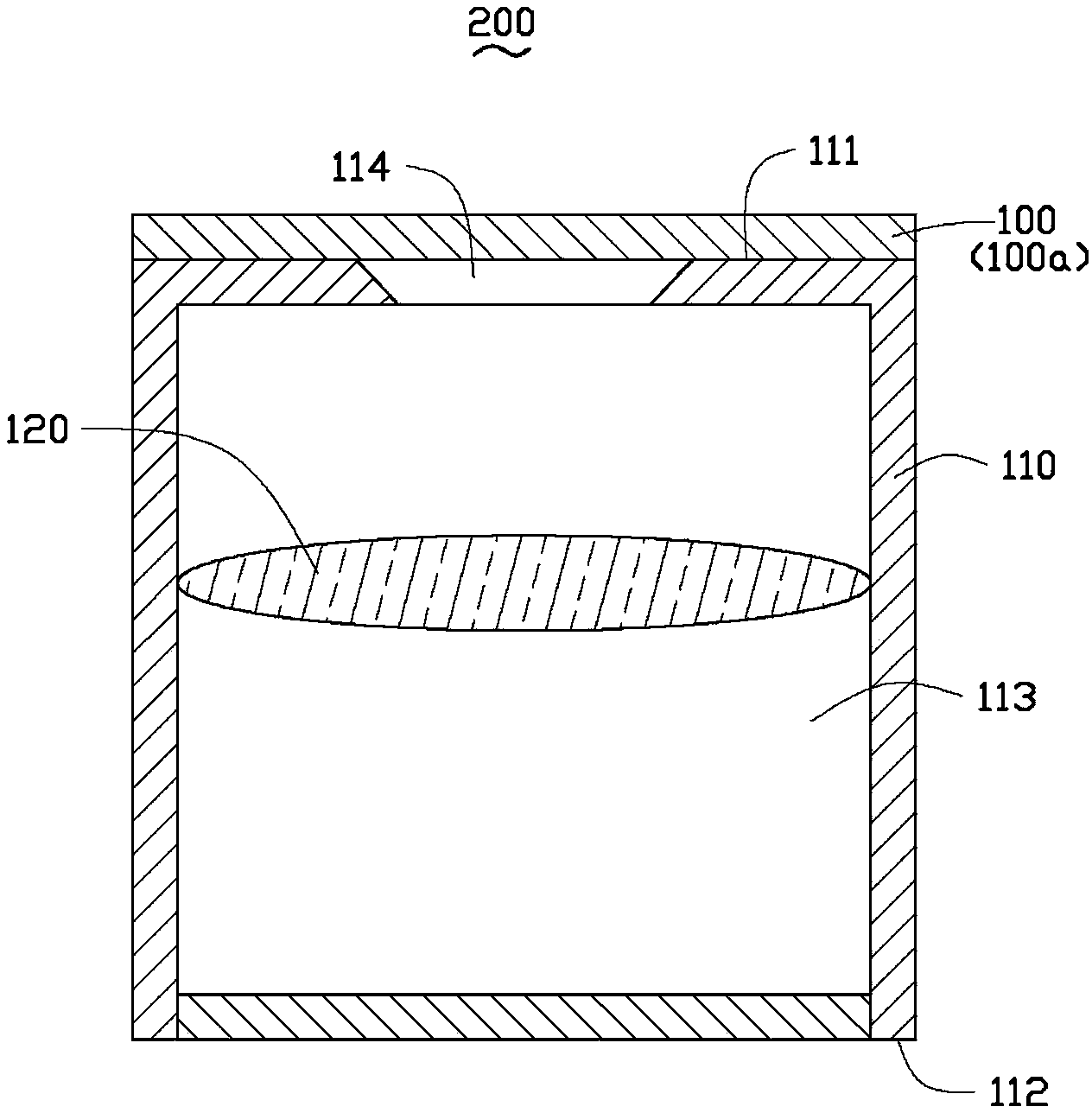

[0013] like figure 1 As shown, an infrared cut filter 100 provided in the first embodiment of the present invention includes a substrate 10 and an infrared cut film 20 plated on the substrate 10 . The infrared cut-off filter 100 is used to filter out the infrared light in the light.

[0014] The substrate 10 is flat and made of sapphire material. The sapphire belongs to the corundum minerals, has a trigonal crystal system, and has a hexagonal structure. The main chemical composition of the sapphire is aluminum oxide (Al 2 o 3 ), its refractive index is 1.760-1.757, and the crystallographic direction of the sapphire is the a axis (11 0), c-axis (0001), m-axis (10 0). The transmittance of the sapphire to infrared light with a wavelength of 825-1300nm is greater than 85%. The substrate 10 includes an upper surface 11 and a lower surface 12 opposite to the upper surface 11 .

[0015] The infrared cut-off film 20 is deposited on the upper surface 11 of the substrate 10 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com