Method for lapping insulated paper tapes for transformers

A technology for transformers and paper tapes, applied in the direction of coil manufacturing, etc., can solve the problems of difficult quantitative control of soaking, inconsistent paper tape bearing capacity, low toughness of insulating paper tapes, etc., to achieve guaranteed insulation performance, smooth wrapping, and uniform infiltration. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for wrapping an insulating paper tape for a transformer, the steps of the method are as follows:

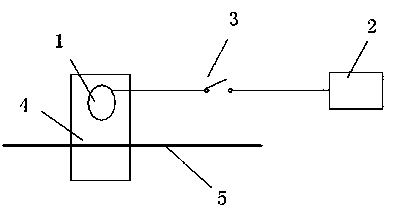

[0014] A spray wet paper device is installed on the paper winding production line, and the spray wet paper device is set behind the paper rack for the insulating paper tape and in front of the winding equipment; for the spray wet paper device, see figure 1 , the device includes a spray wet paper device including a casing 4, a heating atomization spraying device 1 and a humidity detection control device 2, the heating atomization spraying device 1 is arranged in the casing 4, and the heating atomization spraying device 1 is controlled by a power switch 3 Connect with the humidity detection control device 2. The humidity detection control device detects the air humidity in the casing and compares it with the set humidity parameter, and controls the heating atomization spray device through a power switch. The humidity parameter set by the humidity detection control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com