Thin film transistor and manufacturing method, and display apparatus

A technology of thin film transistors and manufacturing methods, which is applied in the field of liquid crystal displays, can solve the problems of easy oxidation of metal layers and metal copper, and achieve the effects of improving oxidation problems, low cost, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

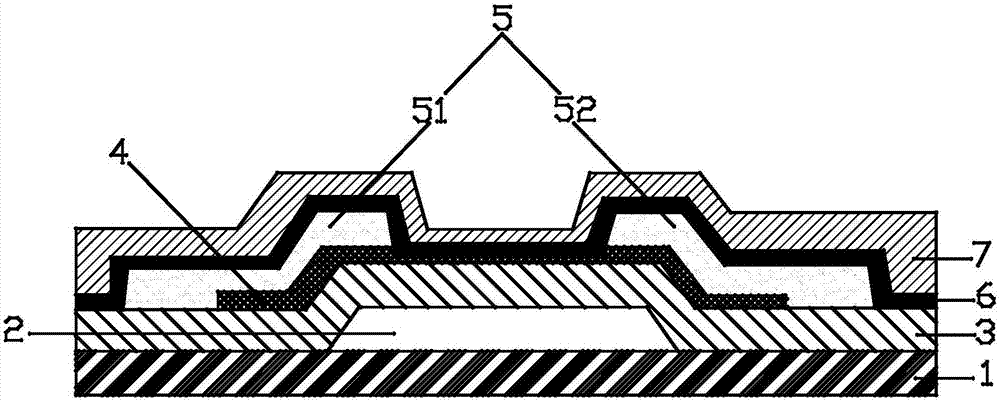

[0049] like Image 6 As shown, the formation of the isolation layer 6 covering the source-drain electrodes 5 and the channel region between the source-drain electrodes 5 specifically includes, under the environment of 170°C-200°C, SiH with a flow ratio of not less than 1:40 4 and N 2 O, formed by a plasma-enhanced chemical vapor deposition process including a thickness of isolation layer of silicon oxide compound. Due to the difference in performance of different devices, the actual process parameters for preparing the isolation layer 6 including the silicon oxide compound are different. In actual preparation, PECVD equipment can be used, the pressure is controlled at 70Pa-110Pa, the power is controlled at 800W-1500W, and the reaction temperature is 170°C-200°C, so that SiH 4 with N 2 O reaction, the deposition thickness on the sample surface is The isolation layer 6; according to different equipment, the deposition rate varies greatly, so the reaction time of the react...

Embodiment 2

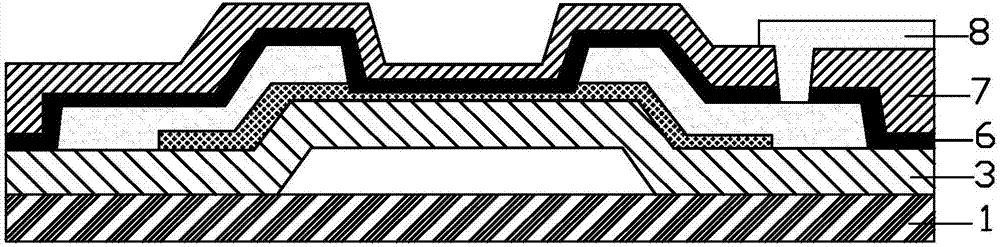

[0052] like Figure 8 As shown, the formation of the isolation layer covering the source-drain electrodes and the channel region between the source-drain electrodes specifically includes forming in an environment of 180°C-220°C through an atomic layer deposition process or a plasma-enhanced atomic layer deposition process. including a thickness of isolation layer of alumina. The reaction gas of alumina is trimethylaluminum gas and its oxidant. The specific operation can be: first pass trimethylaluminum gas, then purify with inert gas, and then pass in H 2 O, H 2 O plasma, O 2 Plasma, O 3 Wait for any source gas in the oxidant to carry out the evaporation reaction; the evaporation reaction can be repeated many times.

[0053] An atomic layer deposition chamber (ALD chamber) can be used for evaporating the aluminum oxide film layer. Due to the use of ALD technology, the deposition rate is relatively slow. Considering the efficiency of mass production, the evaporating thick...

Embodiment 3

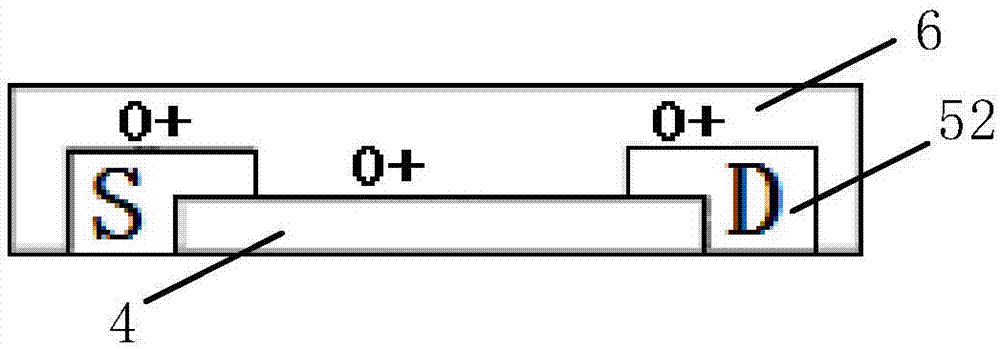

[0058] like Figure 10 As shown, after the deposition of the active layer 4 and the source and drain electrodes 5 is completed, the source and drain electrodes 5 and the channel region between the source and drain electrodes 5 are first subjected to N 2 Oplasma treatment, and then use CVD equipment to vapor-deposit a layer of isolation layer 6; the isolation layer 6 is a silicon oxide compound with low temperature and low oxygen content, and its reaction gas includes SiH 4 and N 2 O, the SiH 4 and N 2 The ratio of O is not less than 1:40, and the evaporation temperature is 170°C-200°C. After completing the vapor deposition of the isolation layer 6, the isolation layer 6 is subjected to N for the second time. 2 Oplasma treatment. After the treatment, a silicon oxide compound with high oxygen content is deposited at a higher temperature as the passivation layer 7, specifically: using PECVD equipment, in an environment of 240°C-280°C, the flow ratio of SiH is not greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com