Combination structure of electronic product shell and plastic part

A technology for electronic products and plastic parts, which is applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, etc., which can solve problems such as complex processing, lower casing strength, and unevenness, and achieve good radiation protection effects, stable bonding, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

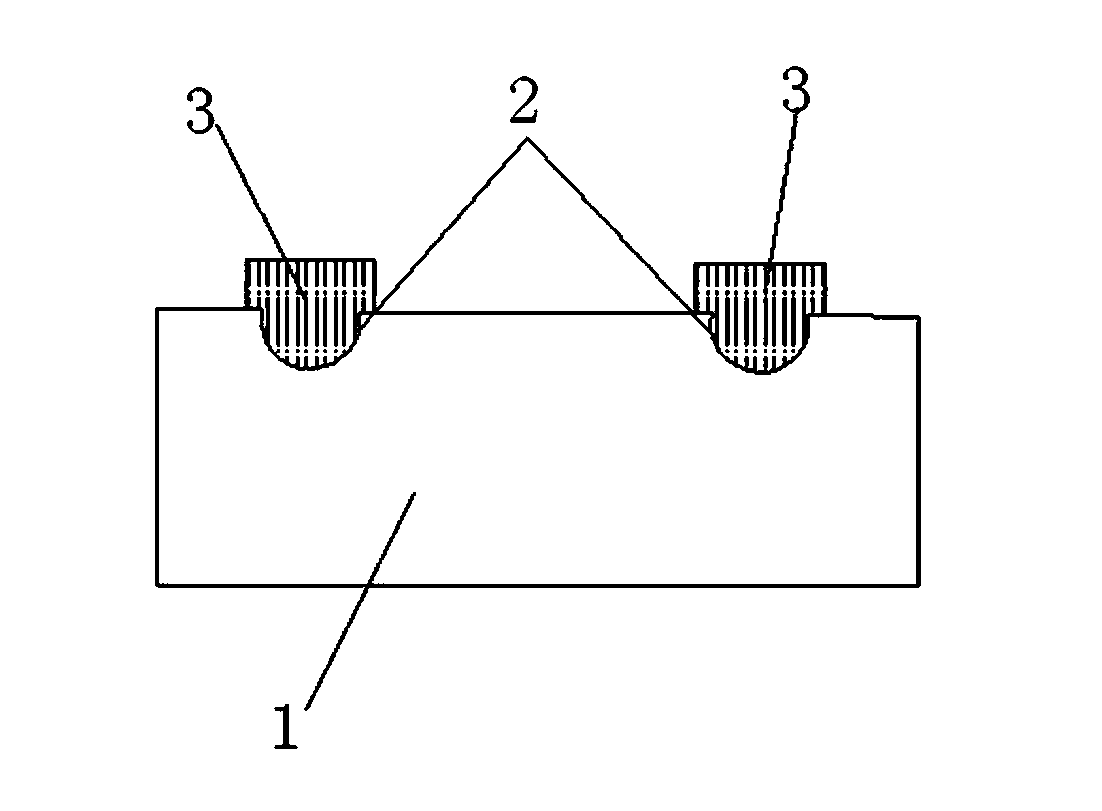

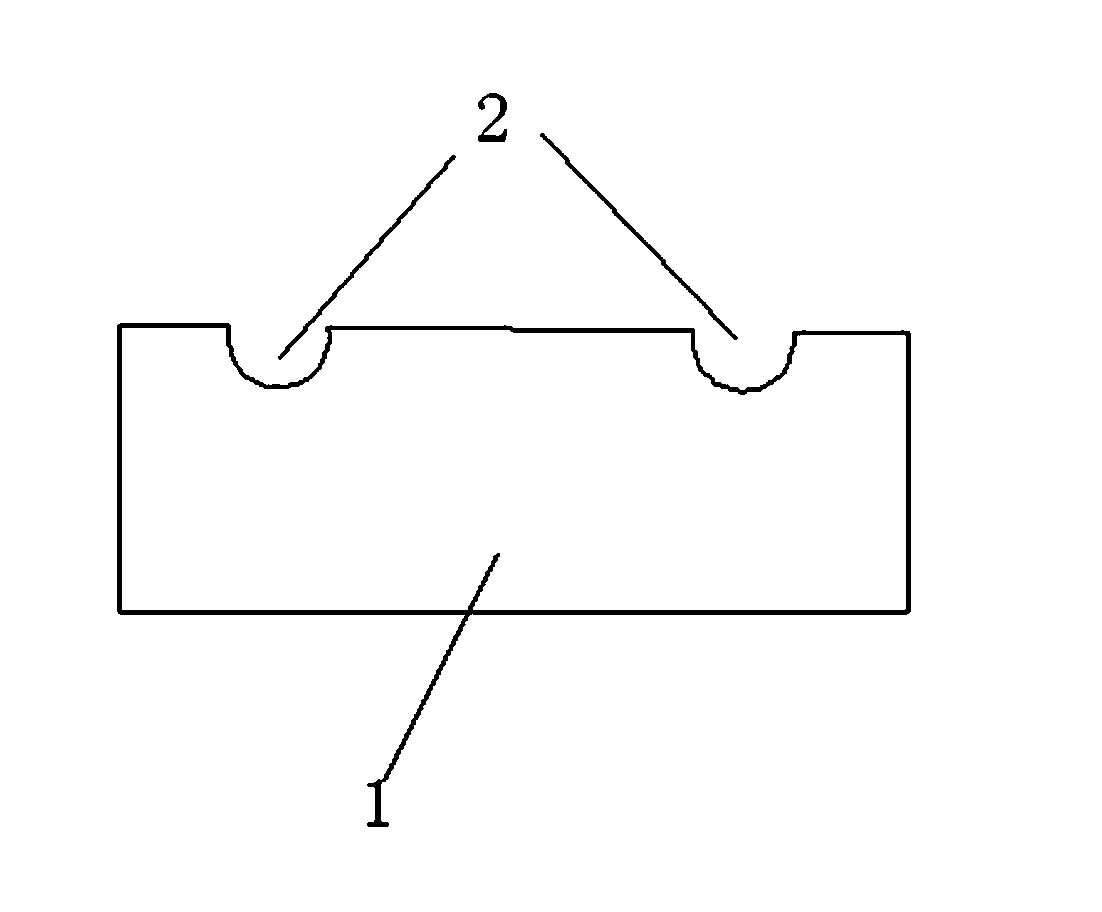

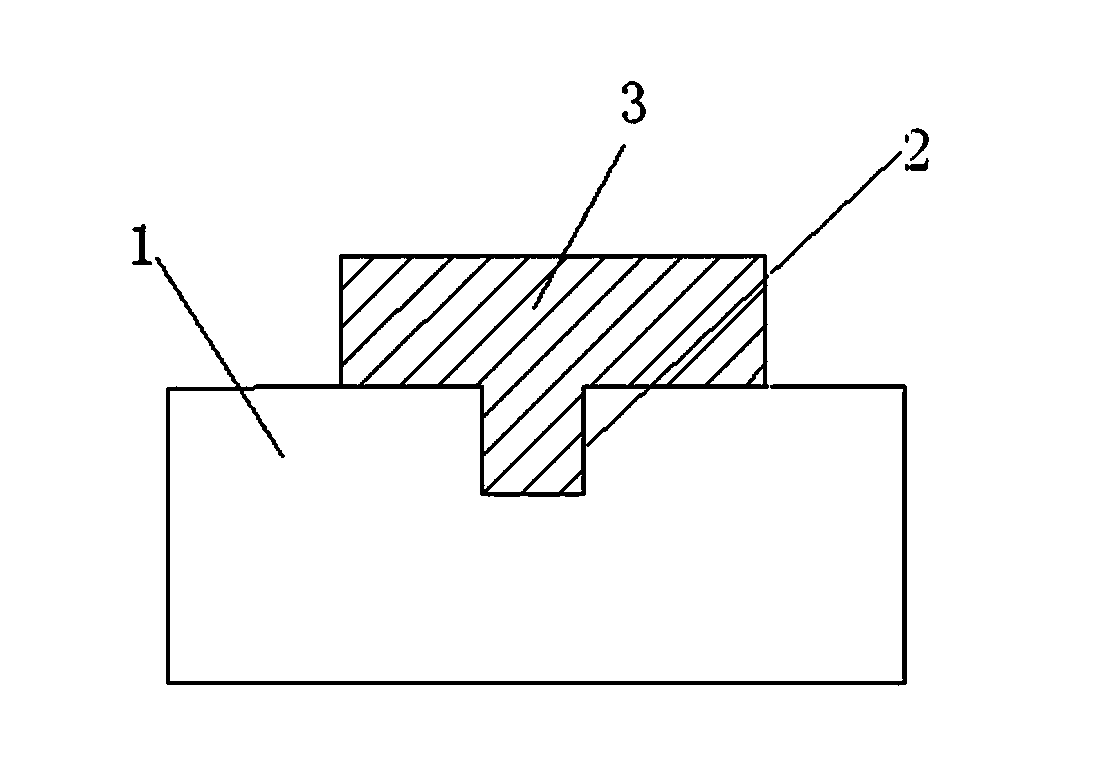

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a combination structure of an electronic product housing and a plastic part includes a housing base material 1 on which a groove 2 is provided, and a plastic part 3 is injection-molded in the groove 2. The piece 3 can cover the groove 2.

[0021] Preferably, the shell substrate 1 is one of metal, metal composite material and non-metal composite material.

[0022] Preferably, the non-metal composite material is one of carbon fiber composite material, glass fiber composite material and aramid composite material.

[0023] Preferably, the groove 2 is one of a round hole shape, a square hole shape and a zigzag shape, and a plastic with a complex structure can be formed by the hole-shaped groove or the zigzag groove and the insert injection molding process. After forming and combining, the plastic part and the electronic product housing are more stable. However, other shapes of groove structures and simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com