Preparation method for dried orange peel

A technology of tangerine peel and tangerine peel, which is applied in the field of tangerine peel preparation, can solve the problems of high residual sulfur dioxide in tangerine peel, affect the medicinal value of tangerine peel medicinal materials, and easy volatilization of volatile oil components, so as to improve commercial processing methods, avoid sulfur dioxide pollution, and dry short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

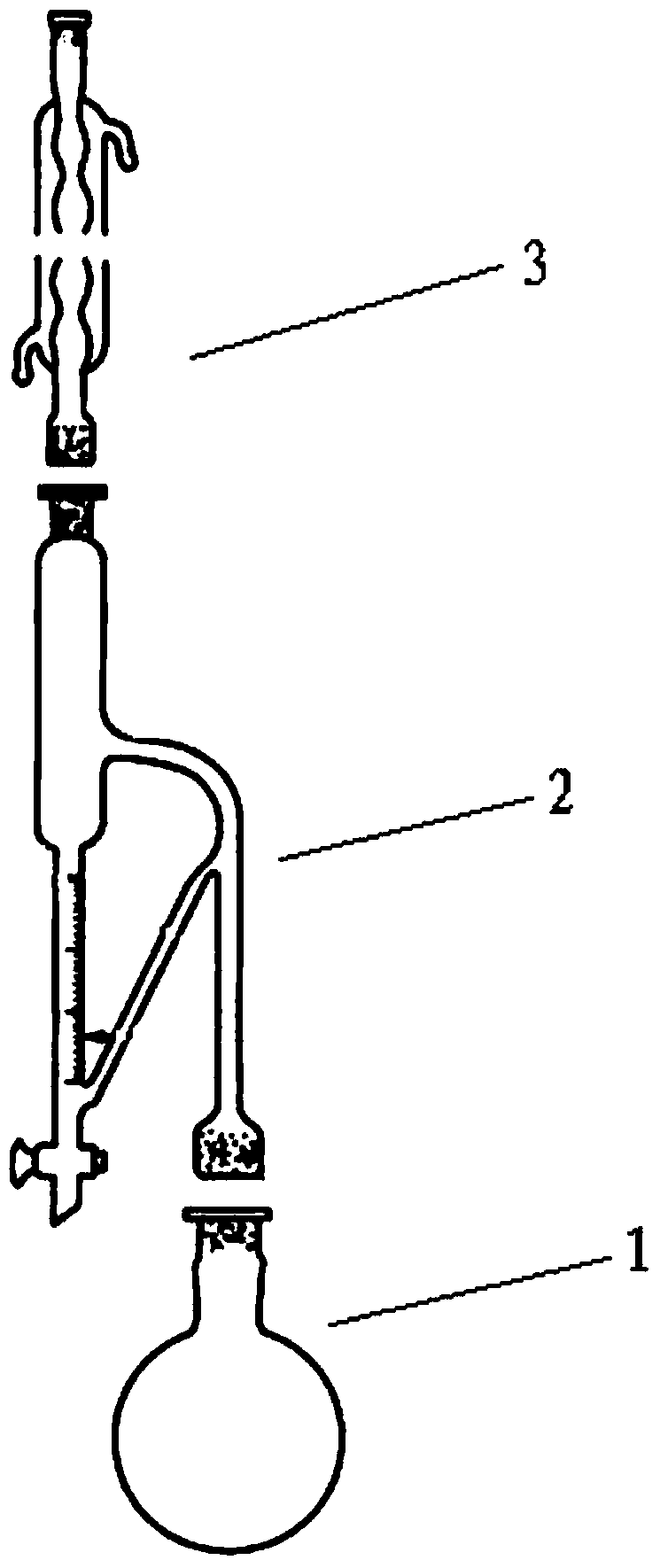

Image

Examples

Embodiment 1

[0041] Blanch the fresh orange peel at 90°C for 30 seconds, peel off the skin to remove mildew, black skin, and sundries; steam dry at 65°C for 6.5 hours to obtain tangerine peel.

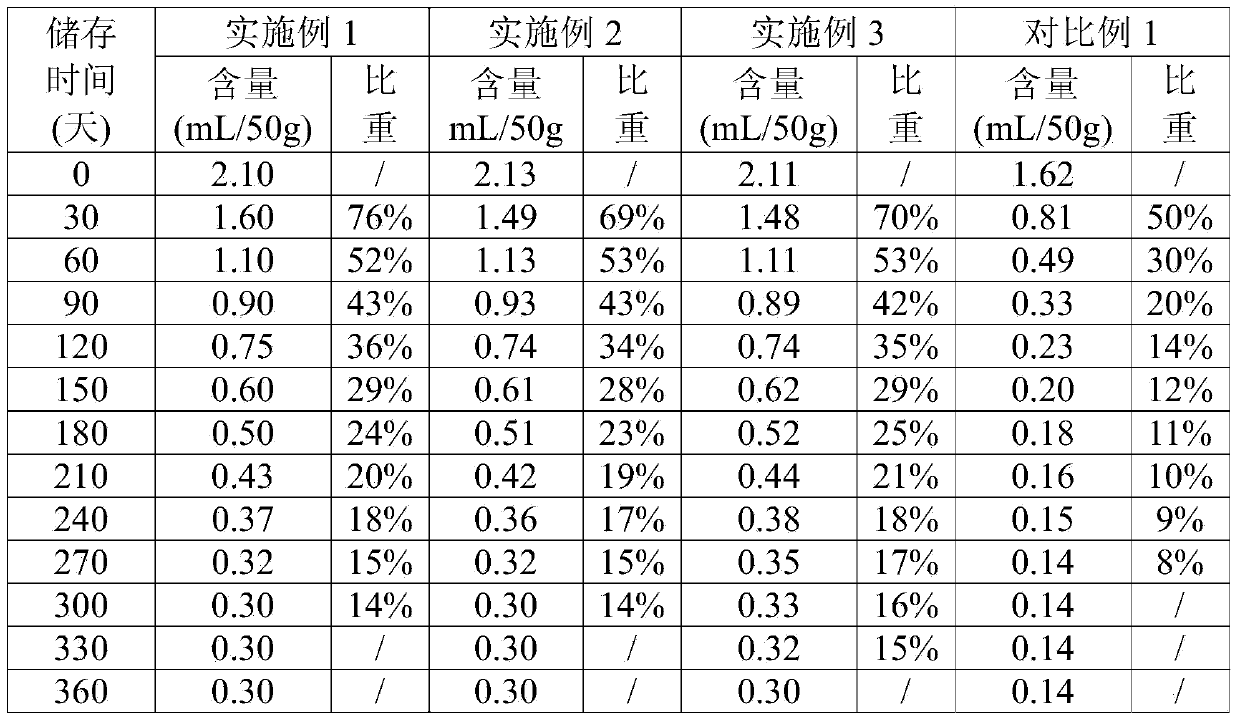

[0042] Volatile oil content is detected by "Chinese Pharmacopoeia" 2010 edition tangerine peel item and appendix XD volatile oil determination method, and sulfur dioxide content is detected by appendix IXU sulfur dioxide residual determination method. The test results are as follows: the content of volatile oil in tangerine peel is 2.10mL / 50g, and the residual amount of sulfur dioxide is <20mg / kg.

Embodiment 2

[0044] The fresh oranges are scalded at 90°C for 30 seconds, and the peels are manually peeled to remove mildew, black skin, sundries, etc. The fresh skin is dried with water steam, at 85°C for 1 hour, then at 75°C for 1 hour, and finally at 65°C for 2 hours; completely dry to obtain tangerine peel.

[0045] According to " Chinese Pharmacopoeia " 2010 editions appendix XD and the method for recording in IXU detect the content of volatile oil and sulfur dioxide in orange peel, test result is as follows: the content of volatile oil in orange peel is 2.13mL / 50g, sulfur dioxide residual amount<20mg / kg.

Embodiment 3

[0047] Blanch the fresh oranges at 90°C for 30 seconds, peel them manually to remove moldy skin, black skin, and sundries; dry the fresh peels with water steam, and bake them at 90°C, 80°C, 70°C and 65°C in sequence. Dry for 1 hour to get tangerine peel.

[0048] Press " Chinese Pharmacopoeia " 2010 editions appendix XD and the method for recording in IXU to detect the content of volatile oil and sulfur dioxide in dried orange peel, test result is as follows: the content 2.11mL / 50g of volatile oil in dried orange peel, residual amount of sulfur dioxide<20mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com