Rectification and separation device and method

A technology of rectification and equipment, which is applied in the field of rectification and separation of isomers of nitrochlorobenzene, and can solve problems such as complex technology and huge investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

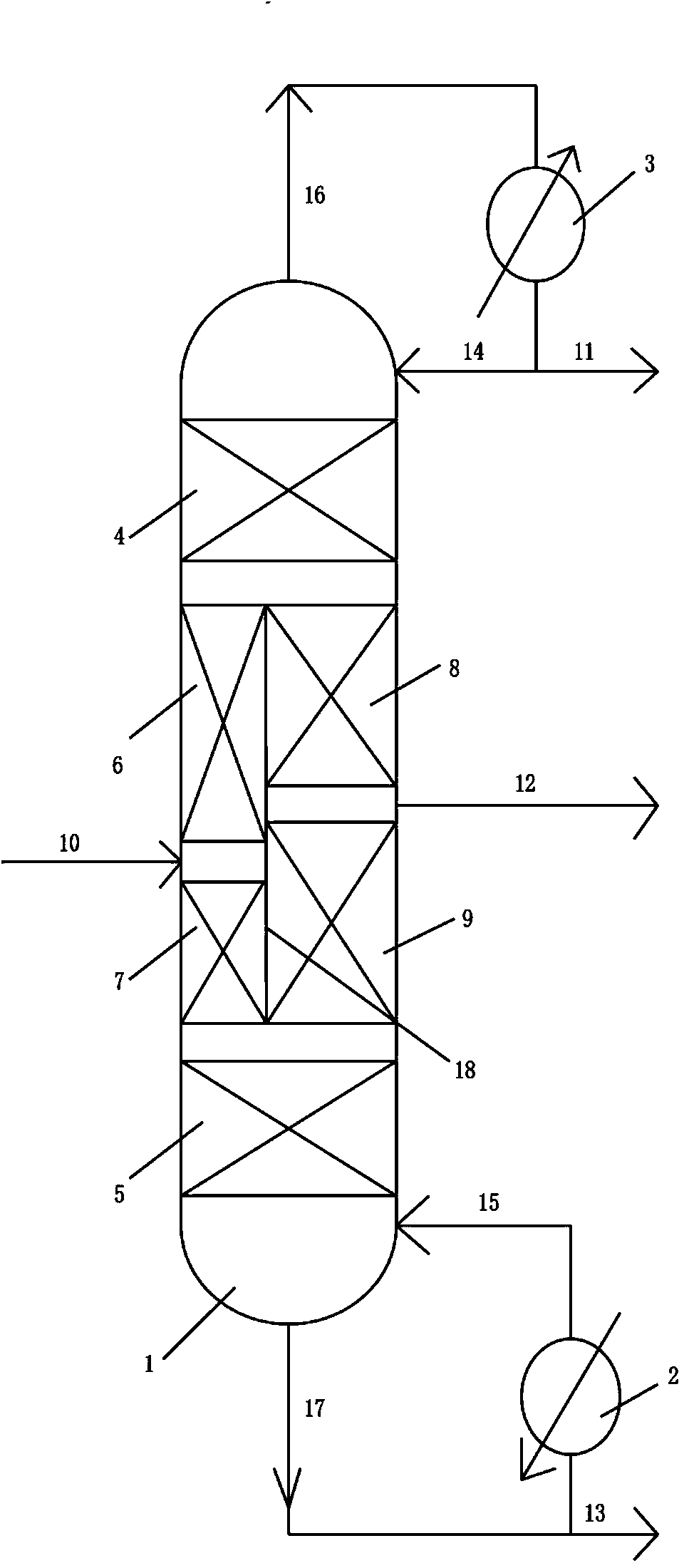

no. 1 example

[0035] According to the first embodiment of the present invention, the dividing wall column 1 is used to separate the nitrochlorobenzene raw material containing m-, p-, ortho-isomers, and the mixture is composed of 1% m-nitrochlorobenzene, 60% p-nitro Chlorobenzene and 39% o-nitrochlorobenzene composition. The mixture of m-, p-, o-nitrochlorobenzene enters the dividing wall column 1 with a bubble point of 1000kg / hr flow rate. The number of theoretical plates in the pre-separation tower is 118, and the feed plate is the 85th theoretical plate in the pre-separation tower area. The number of theoretical plates in the m-p-nitrochlorobenzene separation tower area is 236, of which 186 are in the rectifying section 4 at the top of the tower, and 50 are in the upper m-p-nitrochlorobenzene stripping section 8. The number of theoretical plates in the p- and o-nitrochlorobenzene separation tower area is 176, of which 95 are in the lower p- and o-nitrochlorobenzene rectification section ...

no. 2 example

[0037] According to the second embodiment of the present invention, a dividing wall column 1 is used to separate the nitrochlorobenzene raw material containing m-, p-, ortho-isomers, and the mixture is composed of 5% m-nitrochlorobenzene, 60% p-nitro Chlorobenzene and 35% o-nitrochlorobenzene composition. The mixture of m-, p-, o-nitrochlorobenzene enters the dividing wall column 1 with a bubble point of 1000kg / hr flow rate. The number of theoretical plates in the pre-separation tower is 93, and the feed plate is the 68th theoretical plate in the pre-separation tower area. The number of theoretical plates in the m- and p-nitrochlorobenzene separation tower area is 178, of which 113 are in the rectifying section 4 at the top of the tower, and 65 are in the upper m- and p-nitrochlorobenzene stripping section 8. The number of theoretical plates in the p- and o-nitrochlorobenzene separation tower area is 155, of which 78 are in the lower p- and o-nitrochlorobenzene rectification ...

no. 3 example

[0039] According to the third embodiment of the present invention, a dividing wall column 1 is used to separate the nitrochlorobenzene raw material containing m-, p-, ortho-isomers, and the mixture is composed of 15% m-nitrochlorobenzene, 67% p-nitro Chlorobenzene and 18% o-nitrochlorobenzene composition. The mixture of m-, p-, o-nitrochlorobenzene enters the dividing wall column 1 with a bubble point of 1000kg / hr flow rate. The number of theoretical plates in the pre-separation tower is 103, and the feed plate is the 55th theoretical plate in the pre-separation tower area. The number of theoretical plates in the m- and p-nitrochlorobenzene separation tower area is 163, of which 90 are in the rectifying section 4 at the top of the tower, and 73 are in the upper m- and p-nitrochlorobenzene stripping section 8. The number of theoretical plates in the p- and o-nitrochlorobenzene separation tower area is 147, of which 65 are in the lower p- and o-nitrochlorobenzene rectification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com