Production method for improving purity of o-nitrochlorobenzene

A technology of o-nitrochlorobenzene and its production method, which is applied in the production field of improving the purity of o-nitrochlorobenzene, can solve the problems of long production cycle, insufficient purity, high energy consumption, etc., and achieve the effect of reducing energy consumption and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

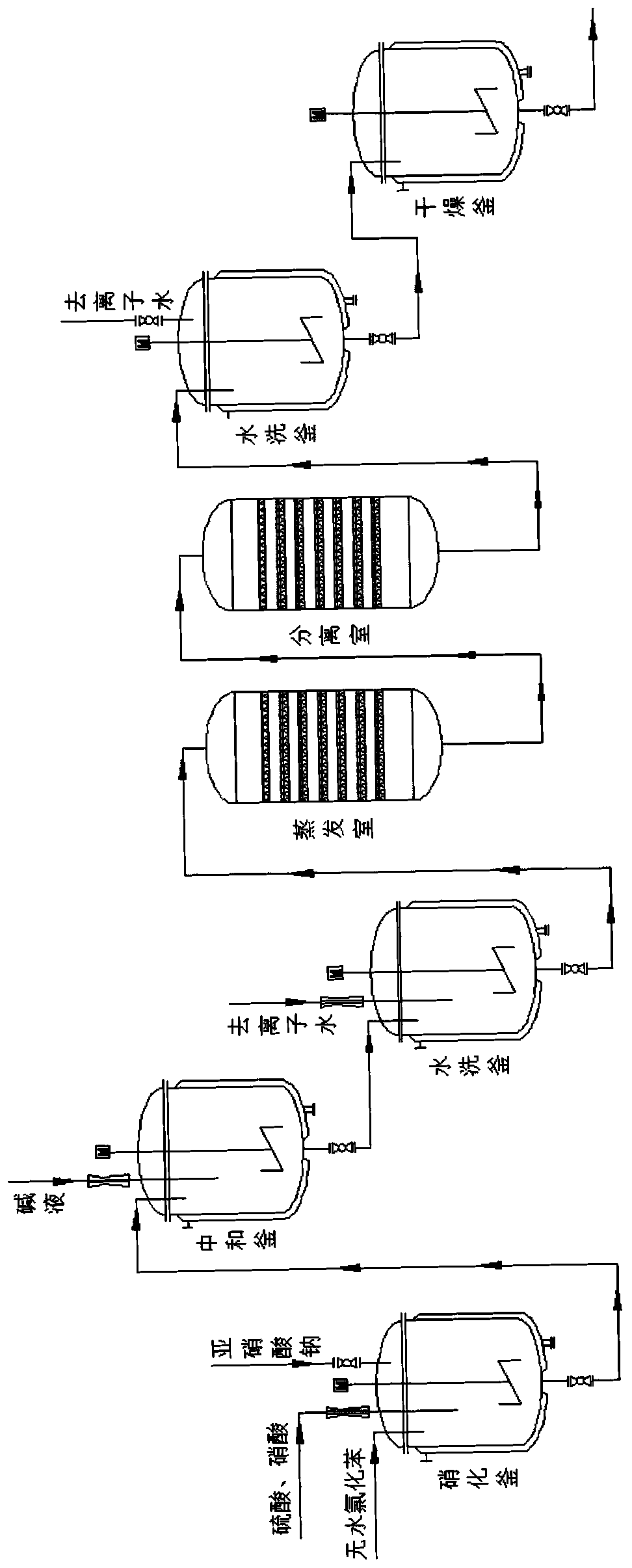

[0025] see figure 1 As shown, the technical solution adopted in the present invention is: a production method for improving the purity of o-nitrochlorobenzene, the production system used in the production method includes a nitration tank, and the downstream connection of the nitration tank is used to neutralize waste acid The neutralization tank, the downstream of the neutralization tank is connected to the water washing tank for washing impurities, the downstream of the water washing tank is connected to the evaporation chamber and the separation chamber participating in the azeotropic separation, and the downstream of the separation chamber is connected to the water washing tank for washing impurities , the downstream of the washing kettle is connected to a drying kettle for drying products;

[0026] The concrete of described production method comprises the following steps:

[0027] (1). Nitrification: Add anhydrous chlorinated benzene, sulfuric acid solution and nitric aci...

Embodiment 2

[0039] see figure 1 As shown, the technical solution adopted in the present invention is: a production method for improving the purity of o-nitrochlorobenzene, the production system used in the production method includes a nitration tank, and the downstream connection of the nitration tank is used to neutralize waste acid The neutralization tank, the downstream of the neutralization tank is connected to the water washing tank for washing impurities, the downstream of the water washing tank is connected to the evaporation chamber and the separation chamber participating in the azeotropic separation, and the downstream of the separation chamber is connected to the water washing tank for washing impurities , the downstream of the washing kettle is connected to a drying kettle for drying products;

[0040] The concrete of described production method comprises the following steps:

[0041](1). Nitrification: Add anhydrous chlorinated benzene, sulfuric acid solution and nitric acid...

Embodiment 3

[0053] see figure 1 As shown, the technical solution adopted in the present invention is: a production method for improving the purity of o-nitrochlorobenzene, the production system used in the production method includes a nitration tank, and the downstream connection of the nitration tank is used to neutralize waste acid The neutralization tank, the downstream of the neutralization tank is connected to the water washing tank for washing impurities, the downstream of the water washing tank is connected to the evaporation chamber and the separation chamber participating in the azeotropic separation, and the downstream of the separation chamber is connected to the water washing tank for washing impurities , the downstream of the washing kettle is connected to a drying kettle for drying products;

[0054] The concrete of described production method comprises the following steps:

[0055] (1). Nitrification: Add anhydrous chlorinated benzene, sulfuric acid solution and nitric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com