Preparation method for light hydrocarbon copper sheet corrosion inhibitor

A copper corrosion and inhibitor technology, applied in the preparation of hydrazine, organic chemistry, etc., can solve problems such as danger, copper corrosion performance is not up to standard, copper parts corrosion, etc., to reduce copper corrosion and stabilize light hydrocarbon copper. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

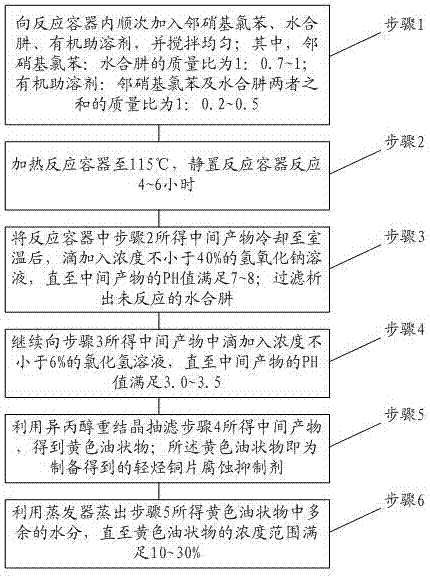

[0021] Such as figure 1 As shown, the invention provides a kind of preparation method of light hydrocarbon copper sheet corrosion inhibitor, and this preparation method comprises the following steps:

[0022] Step 1: Add o-nitrochlorobenzene, hydrazine hydrate, and organic co-solvent sequentially into the reaction vessel, and stir evenly; wherein, the mass ratio of o-nitrochlorobenzene:hydrazine hydrate is 1:0.7∼1; the organic co-solvent : The mass ratio of the sum of o-nitrochlorobenzene and hydrazine hydrate is 1:0.2∼0.5;

[0023] Specifically, the purity of the o-nitrochlorobenzene selected for use is not less than 99%, and the purity of the hydrazine hydrate used is not less than 85%; and the organic co-solvent is any one of isopropanol, ethanol, methanol or Several kinds.

[0024] Step 2: Heat the reaction vessel to 115°C, and let the reaction vessel stand for 4∼6 hours;

[0025] Further, on the basis of completing step 1, the reaction vessel is heated. Specifically, ...

Embodiment approach

[0032] As a preferred embodiment of the present invention, the preparation method provided by the present invention also includes:

[0033] Step 6: Use an evaporator to evaporate excess water in the yellow oil obtained in step 5 until the concentration range of the yellow oil satisfies 10∼30%.

[0034] Wherein, excess water may remain in the yellow oil obtained in step 5, so it is preferable to use an evaporator to evaporate the excess water, and it is advisable to satisfy the concentration of light hydrocarbon copper corrosion inhibitor at 10∼30%.

[0035] In order to verify that the inhibitor prepared by the preparation method of the light hydrocarbon copper sheet corrosion inhibitor provided by the present invention is indeed effective, the physical properties of the inhibitor are further analyzed. The light hydrocarbon copper sheet corrosion inhibitor is pale yellow or yellow at room temperature (20∼30°C), and has good miscibility with light hydrocarbons, and can be comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com