Channel type sorting mechanism of color selector and sorting method

A color sorter and channel-type technology, applied in the field of color sorters, can solve problems such as low adjustability, inapplicability of materials with larger particles, and high noise, so as to avoid redundant design, simple installation and debugging, and low energy consumption. consumption and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

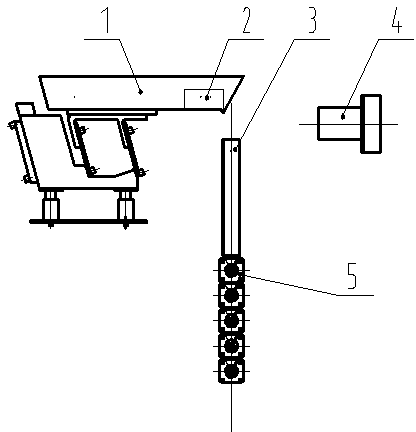

[0019] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , figure 2 As shown, a channel-type color sorter sorting mechanism includes a vibrating feeding table 1, a material guide tube 3, a camera 4 and a paddle-type stepping motor sorting mechanism 5, and the outlet end of the vibrating feeding table 1 is provided with a Make the material fall into the passage dividing plate 2 corresponding to the material guiding pipe 3, the material guiding pipe 3 is located directly below the outlet end of the vibrating feeding table 1, and the shooting range of the camera 4 is between the vibrating feeding table 1 and the material guiding pipe 3 . The camera 4 is connected with the image signal processing control system, and the pictures taken are input into the control system, and after the judgment, the movement of the plectrum is controlled to achieve the purpose of sorting.

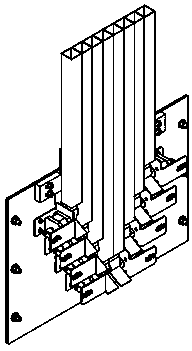

[0020] The paddle-type stepping motor sorting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com