Soft package battery cell unit, corresponding manufacturing method and battery pack

A technology for battery packs and soft packs, which is applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrical components, etc., can solve the problems of large structural space of battery modules, difficult module assembly, and occupying the internal space of battery packs, so as to improve the Group efficiency and energy density, construction space saving, effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and beneficial technical effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and multiple exemplary embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the protection scope of the present invention. Here, for reasons of simplicity, elements with the same reference number are identified only once in the figures.

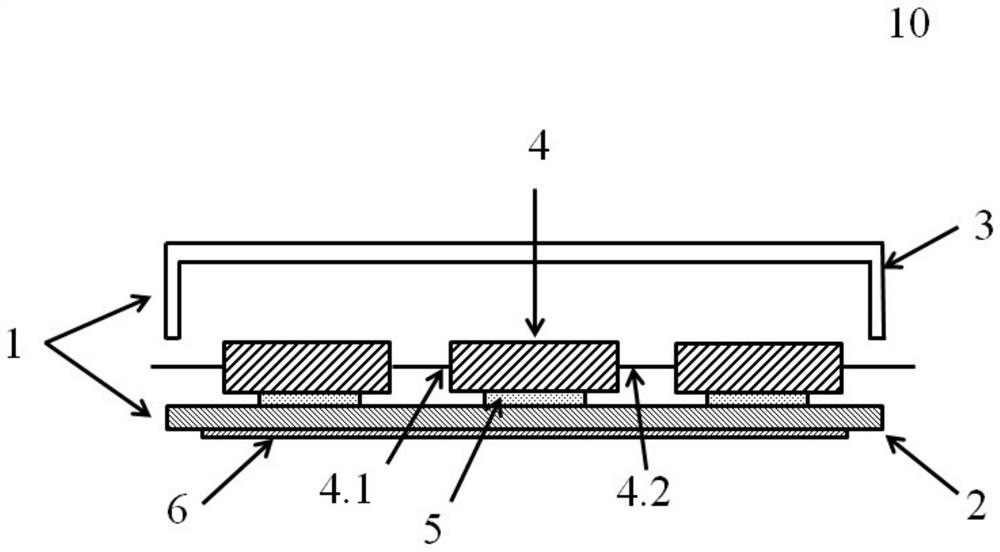

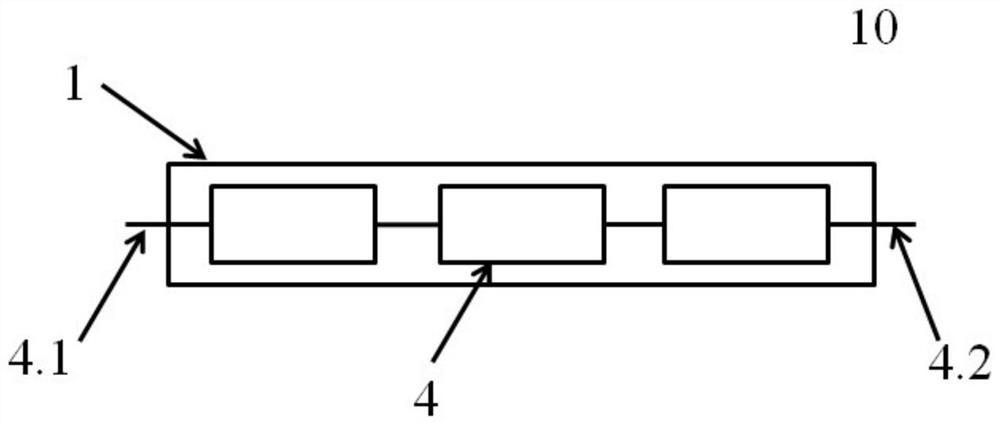

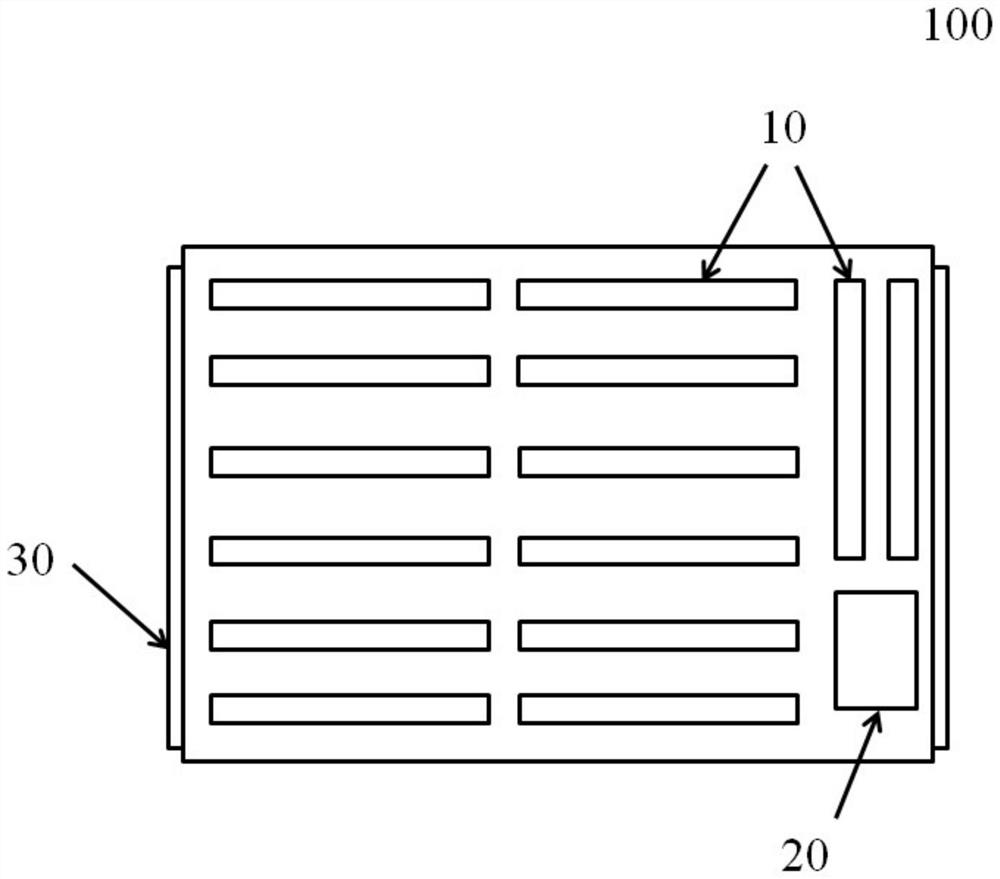

[0030] figure 1 A schematic diagram of a pouch cell unit 10 according to an exemplary embodiment of the present invention is shown.

[0031] Such as figure 1 As shown, the pouch cell unit 10 has a housing 1 composed of a carrier plate 2 and a frame 3 . A plurality of, for example three, pouch cells 4 are arranged inside the housing 1 . Of course, those skilled in the art can also arrange other num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com