Test panel welding fixture

A welding tool and test plate technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of test plate deformation, waste of resources, warping heads, etc., achieve stable support, reduce labor intensity, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

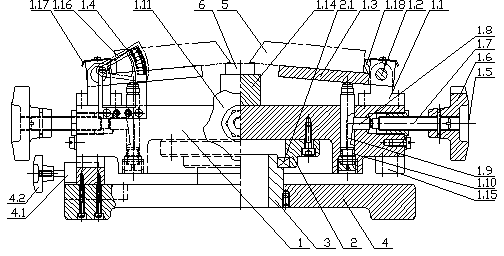

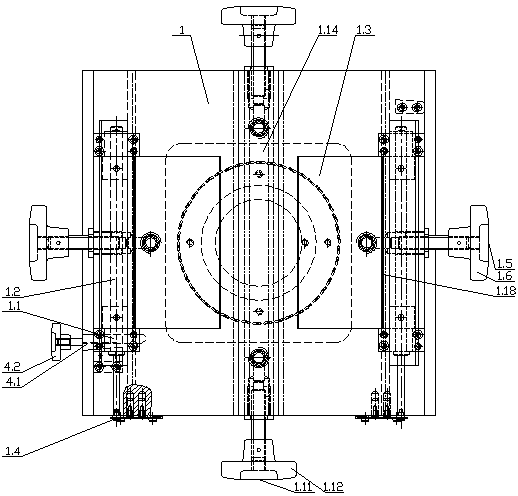

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

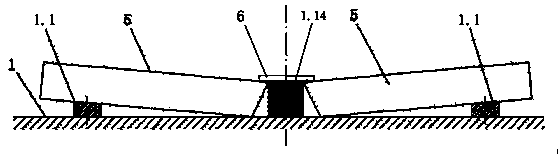

[0023] like figure 2 , image 3 , Figure 4 As shown, the welding tooling of the test plate includes a clamp body 1, a flange plate 2, a support column 3 and a base 4.

[0024] The clamp body 1 is a square structure, which is symmetrically arranged horizontally and vertically. The left and right symmetrical edges of the upper surface of the clamp body 1 are respectively provided with a support frame 1.1, and the support frame 1.1 is provided with a hinge shaft 1.2 hingedly connected thereto. Two support plates 1.3 is arranged symmetrically, one end is fixedly connected to the hinge shaft 1.2 respectively, the support plate 1.3 is provided with a baffle plate 1.18 near the root of the hinge shaft 1.2, and the spacer 1.14 is set on the longitudinal centerline of the upper surface of the clamp body 1.

[0025] The dial 1.4 consists of two pieces with a scale range of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com