Electric sanitation vehicle chassis and electric sanitation vehicle with same

A sanitation vehicle and electric technology, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of short cruising range and operating time, easy water entry of power batteries, and inconvenient maintenance of power batteries, so as to increase the cruising range. and working time, strong accidents and natural disasters, good ventilation and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

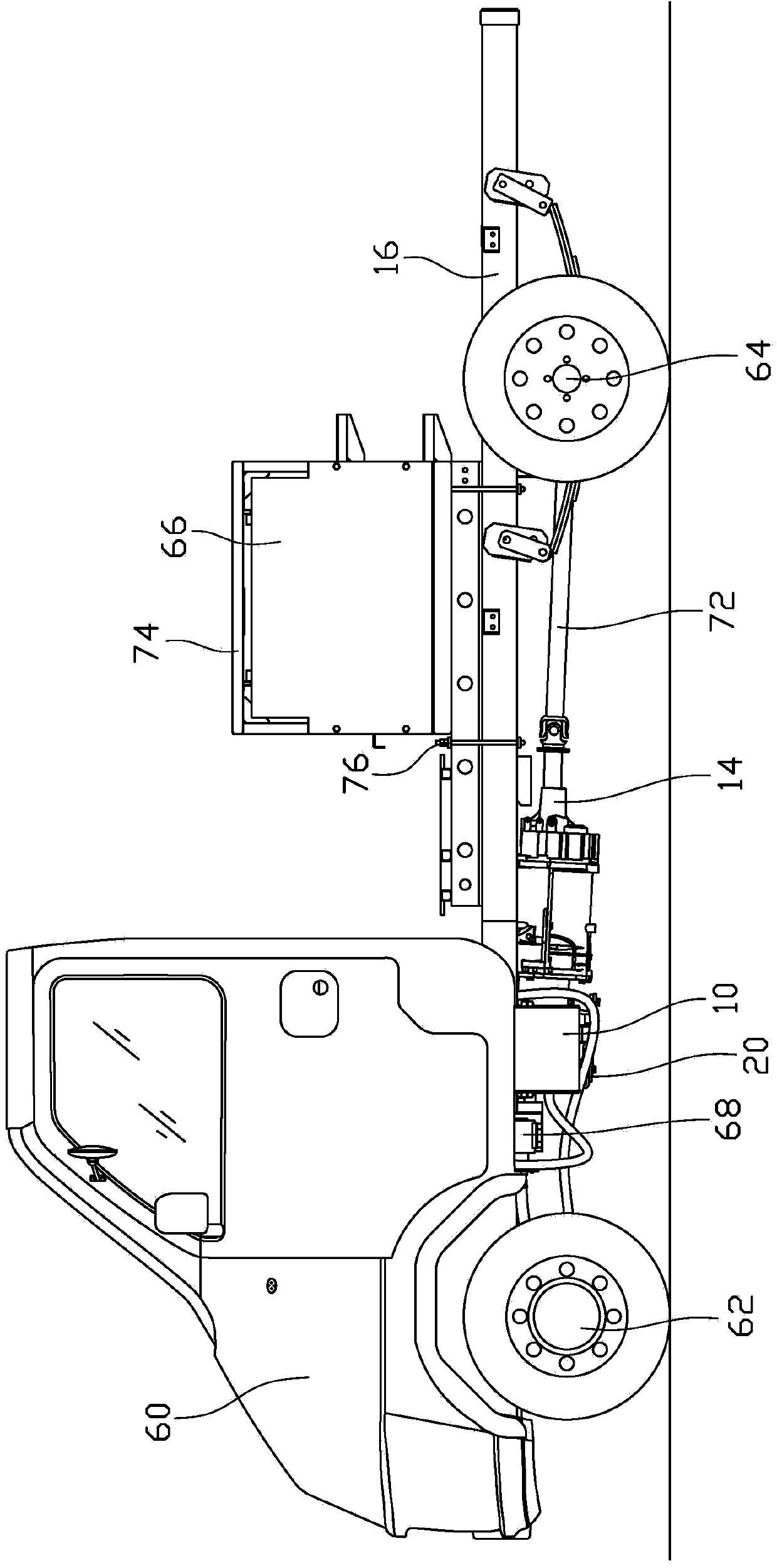

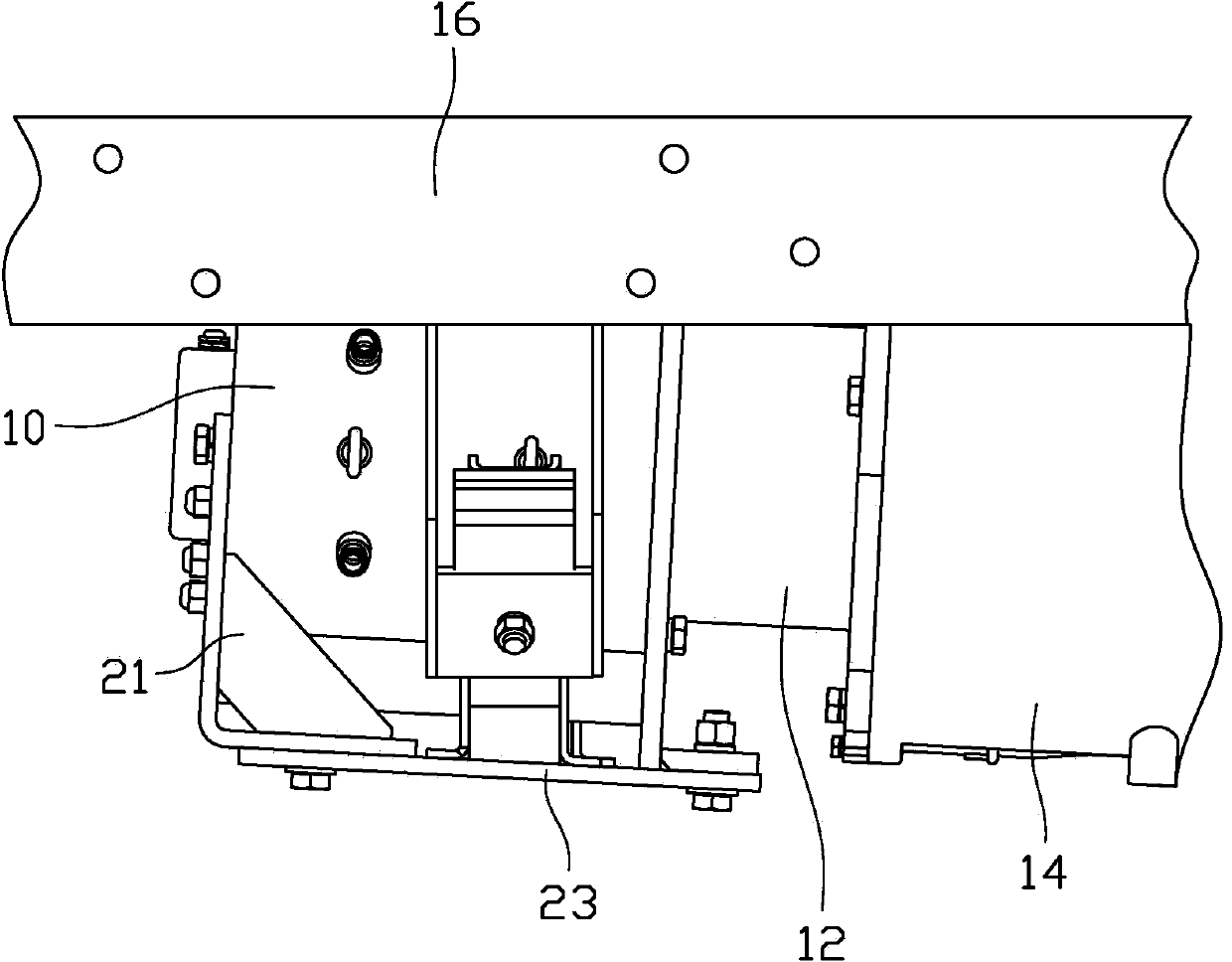

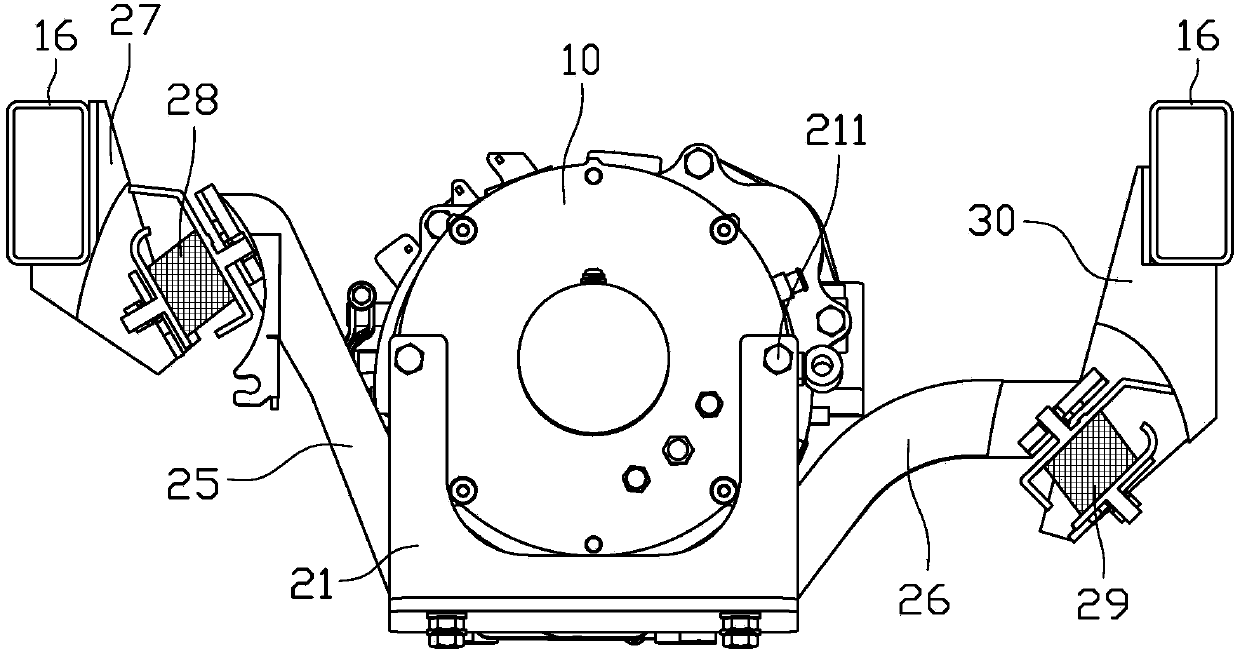

[0032] see figure 1 , the present invention discloses an electric sanitation vehicle chassis, which includes a cab 60, a front axle 62, a rear axle 64, a drive shaft 72, a drive motor 10, a clutch gearbox 14 and a vehicle frame (not shown). The frame includes longitudinal beams 16 . The clutch gearbox 14 is fixed on the vehicle frame. The driving motor 10 is arranged under the cab 60 . The drive motor 10 is connected to the clutch gearbox 14, and the two ends of the transmission shaft 72 are respectively connected to the clutch gearbox 14 and the rear axle 64, so as to transmit the power to the rear axle and realize the motor front and rear drive. Since the drive motor 10 is arranged under the driver's cab 60, the drive motor 10 has a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com