Synchronous telescoping mechanism and autocrane

A technology of telescopic mechanism and retractable arm, which is applied in the direction of cranes, etc., can solve the problems affecting the lifting performance of truck cranes, the weight and cost of the telescopic boom remain high, and achieve the effects of easy disassembly and transportation, improved lifting performance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

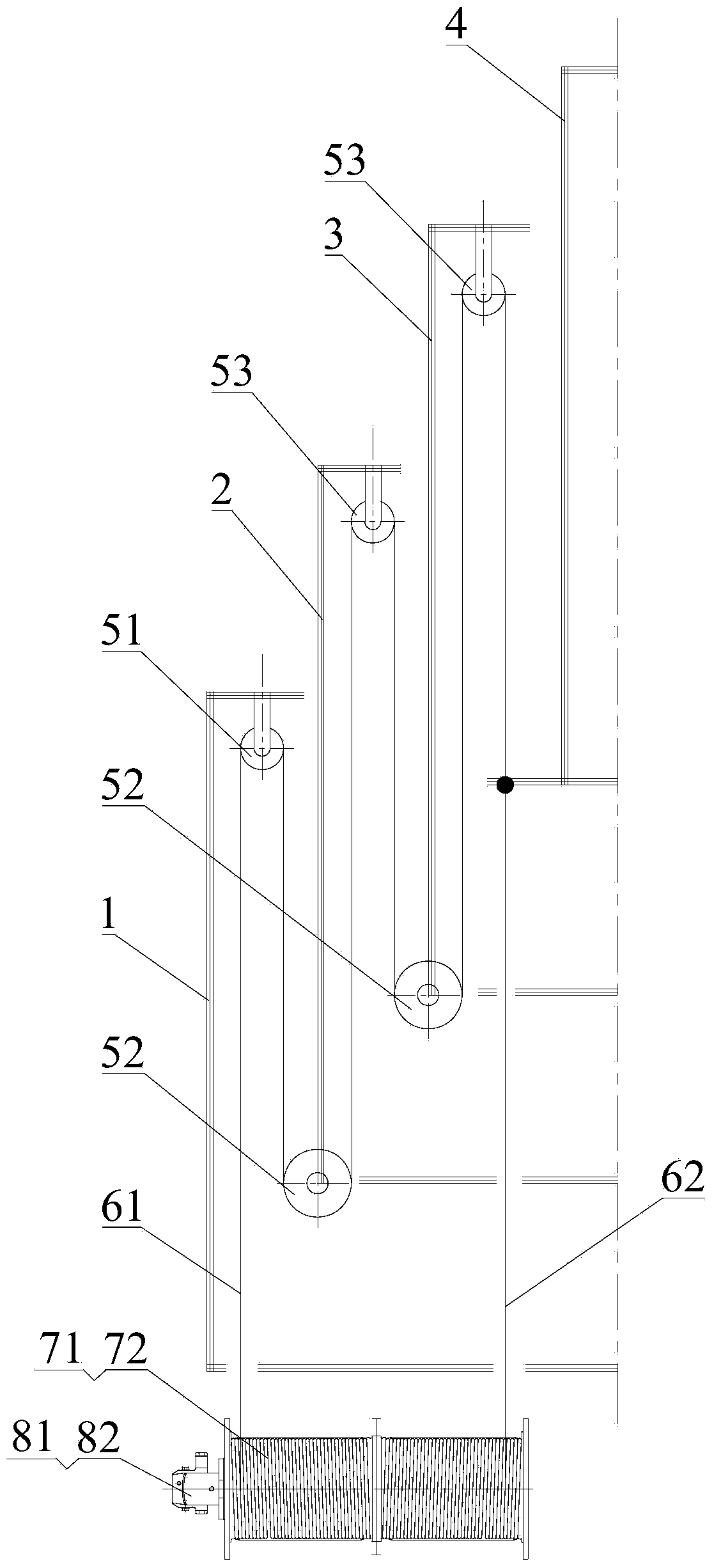

[0019] figure 1 It shows the structural principle diagram of the preferred embodiment of the synchronous telescopic mechanism provided by the present invention. It can be seen from the figure that the synchronous telescopic mechanism includes a basic arm (equivalent to the outer section arm 1, hereinafter referred to as the outer section arm 1), The last section arm (equivalent to the inner section arm 4, hereinafter referred to as the inner section arm 4) sleeved in the outer section arm 1, and the two intermediate sections of the arm 2 and the 3. The outer section arm 1, the intermediate arm 2, the intermediate arm 3 and the inner section arm 4 form a four-section telescopic arm. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com