Floatation equipment

A kind of equipment and air flotation technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of low water reuse standard, low removal rate, low noise, etc., to facilitate early installation and later maintenance, and improve air flotation effect , the effect of improving the efficiency of dissolved gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

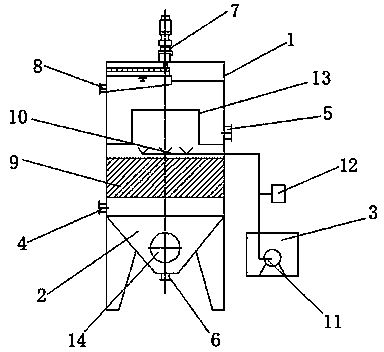

[0012] Such as figure 1 As shown, an air flotation device includes a cylinder body 1, a mud bucket 2 and an air-dissolving device 3, the cylinder body 1 is provided with a water inlet 4 and a water outlet 5, and the bottom of the cylinder body 1 is provided with a mud bucket 2, The mud hopper 2 is provided with a mud outlet 6, the top of the cylinder body 1 is provided with a skimming device 7 and a slag outlet 8, and the cylinder body 1 is provided with a sloping plate section 9, and the sloping plate section 9 is provided with Between the water inlet 4 and the water outlet 5, a micro-nano bubble generator 10 is arranged between the inclined plate section 9 and the water outlet 5, and the micro-nano bubble generator 10 is connected with the gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com