Blast furnace slag discharge trench with built-in water cooling system

A technology of water cooling and slag ditch, applied in the direction of discharge devices, etc., can solve the problems of complex mineral composition, difficult to achieve effects, and poor resistance to slag erosion, etc., achieve low maintenance labor intensity, low manufacturing cost, and no need to consume refractory material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

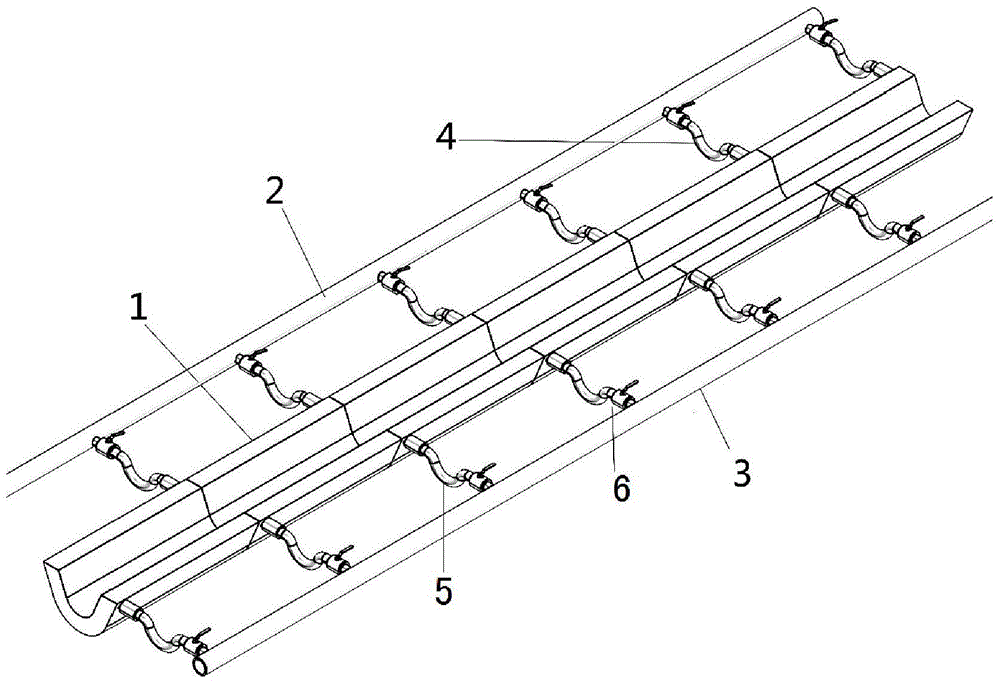

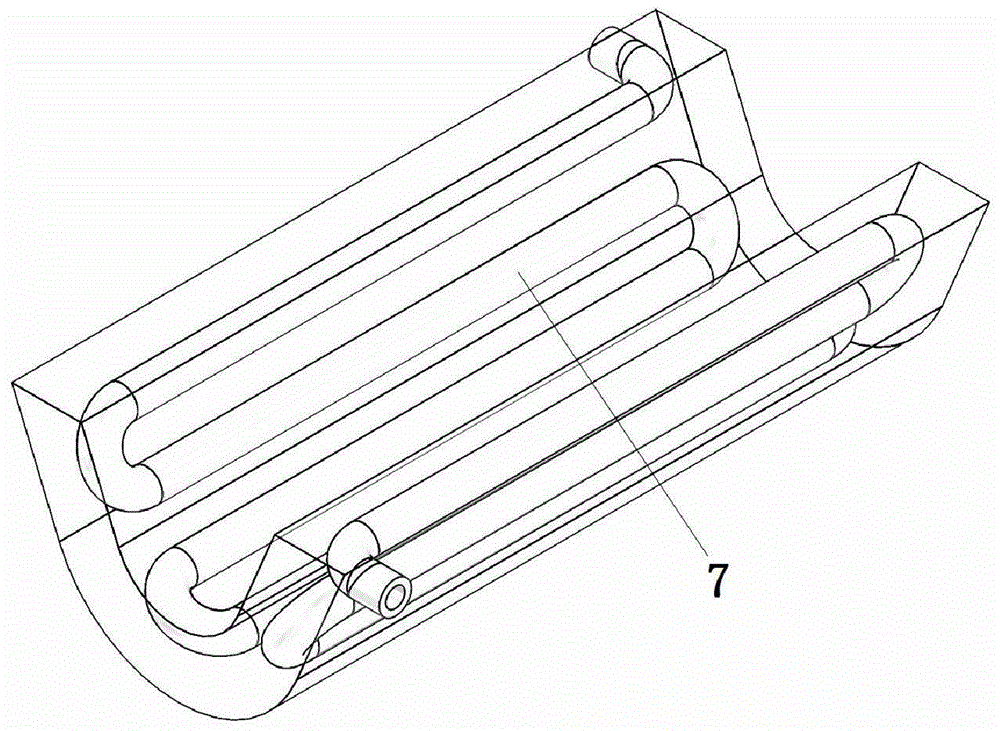

[0016] see figure 1 , the present invention is a blast furnace slag ditch with an embedded water cooling system, which is composed of several cast steel slag ditch bodies 1 arranged in a row. On both sides of the cast steel slag ditch main body 1, a water inlet pipe 2 and a water outlet pipe 3 are respectively provided. see you again figure 2 , The cast steel slag ditch body 1 is a cast steel body with a cavity inside, and a reciprocating bending cooling water pipe 7 made of a seamless steel pipe is embedded in the cavity. The cooling water pipe 7 has a water inlet and a water outlet, and the water inlet and the water outlet are located on both sides of the cast steel slag ditch body 1 respectively. The water inlet pipe 2 and the water outlet pipe 3 are respectively connected to the water inlet and the water outlet of the cooling water pipe 7 through the stainless steel corrugated pipe 4 at the water inlet end and the stainless steel bellows pipe 5 at the water outlet end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com