Sapphire seed chuck with double positioning pins

A seed crystal chuck, sapphire technology, applied in the direction of seed crystal remaining in the melt, single crystal growth, crystal growth, etc. during the growth period, can solve the problems of broken, broken joints, poor centrality, etc., to achieve The effect of dispersing contact stress, preventing seed crystal fracture, and ensuring centrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

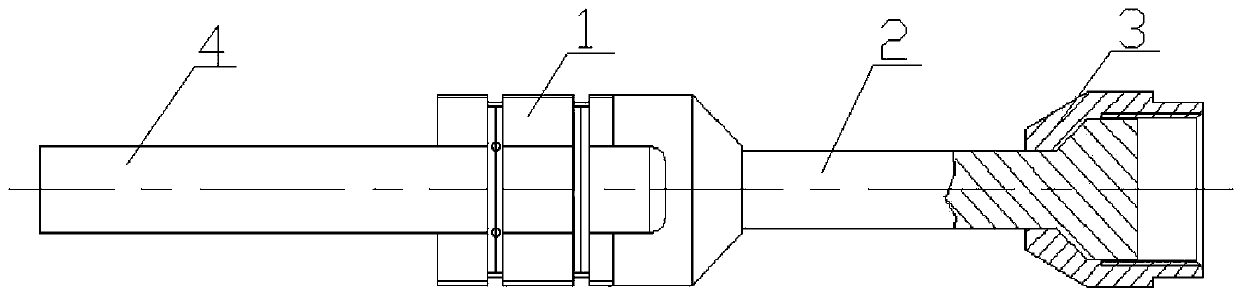

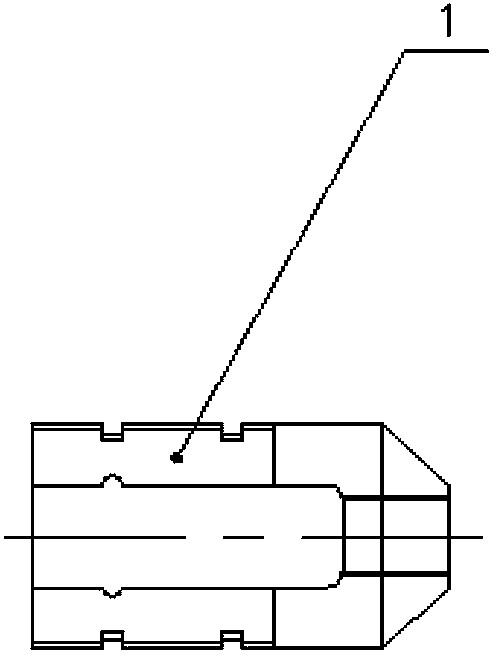

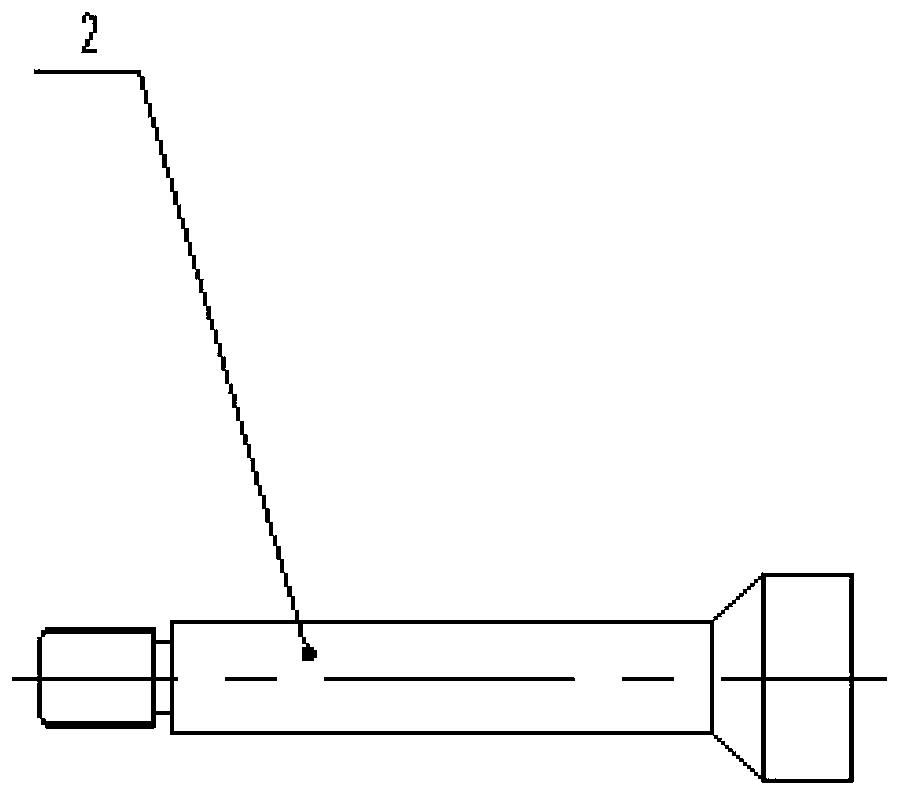

[0024] Such as Figure 1 to Figure 6 As shown, the sapphire seed chuck with double positioning pins includes a connecting body 1, a transition section 2 and a connecting nut 3. The sapphire seed chuck is made of pure molybdenum and is used to clamp a rectangular parallelepiped seed crystal 4. The seed crystal 4 is provided with at least two semicircular grooves, and the seed crystal 4 in this embodiment is provided with two semicircular grooves. One end of the connecting body 1 is provided with a screw hole, and there is a fine internal thread inside the screw hole. The other end of the connecting body 1 has a rectangular installation groove, and the center line of the installation groove coincides with the center line of the sapphire seed crystal chuck. At least one pin hole is provided on both sides of the installation groove, for the double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com