Water jet jacquard loom

A water-jet loom and water-jet device technology, applied in the field of jacquard looms and jacquard water-jet looms, can solve the problems of reduced fabric efficiency, large water flow resistance, and no jacquard faucet, so as to improve product quality and seal Good effects, leading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

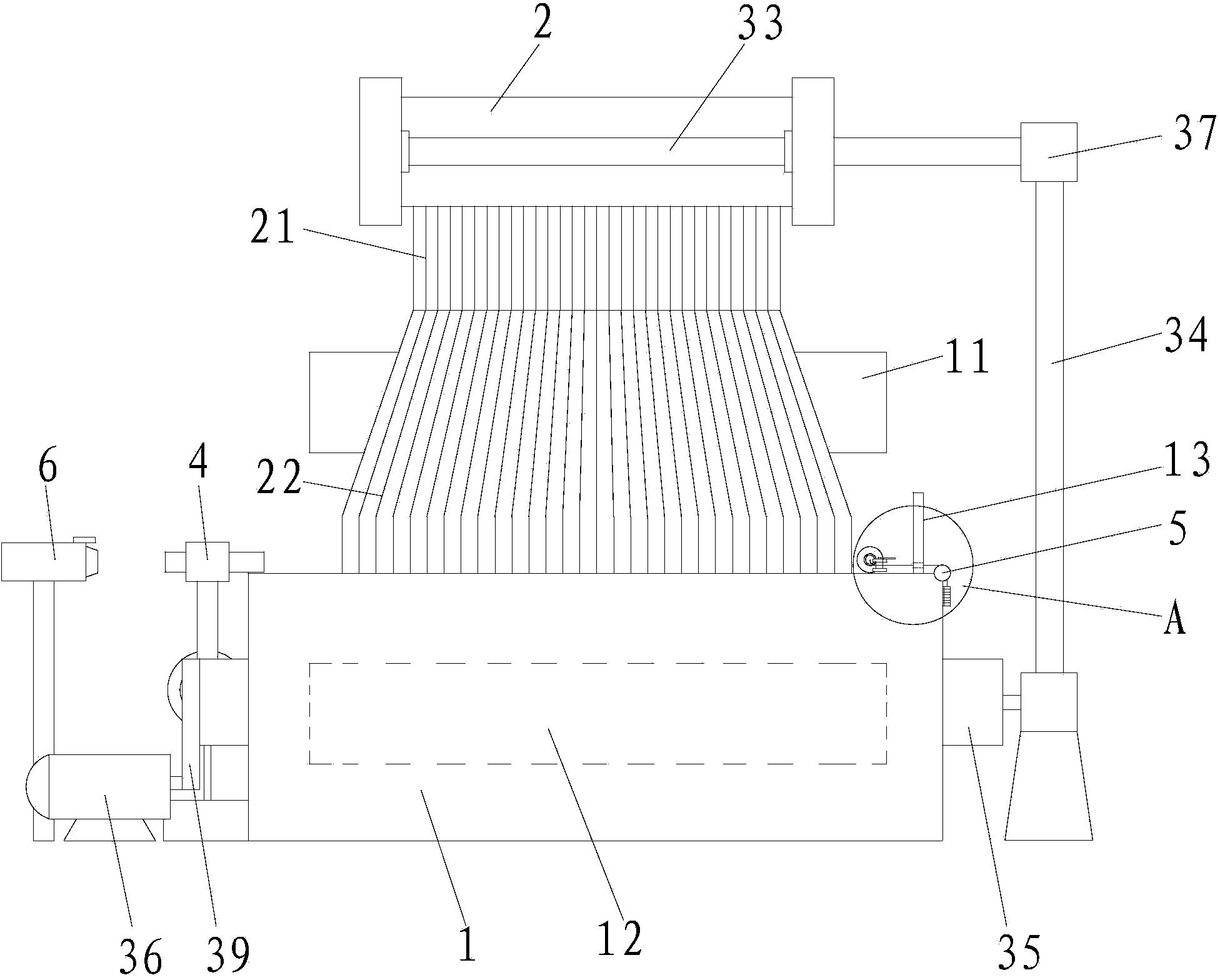

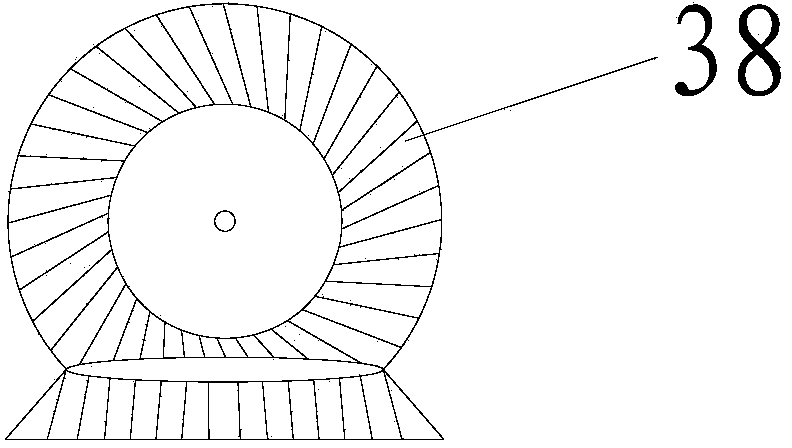

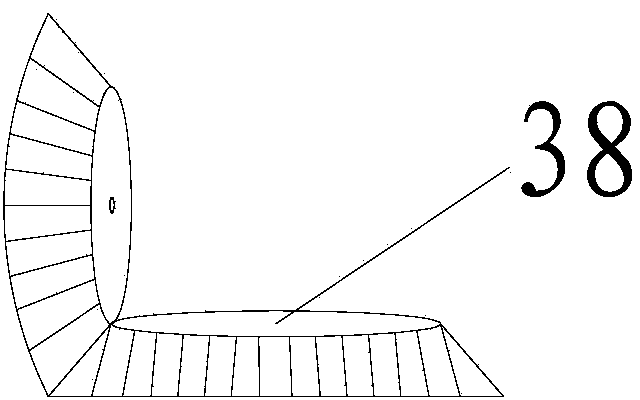

[0032] refer to figure 1 , figure 2with image 3 , a kind of jacquard water-jet loom of the present invention, comprises fuselage 1, jacquard faucet 2, transmission device, water spray device 4, waste edge silk guiding device 5 and weft feeder 6, and the rear side of described fuselage 1 is installed with The upper warp beam 11 and the lower warp beam 12, the jacquard faucet 2 is located above the fuselage 1, the jacquard faucet 2 is connected with the transmission device 3, the water spray device 4 is installed on one side of the fuselage 1, and the waste edge thread guide device 5 is installed On the other side of the fuselage 1, a weft feeder 6 is installed on the side of the water spray device 4 away from the fuselage 1, and a number of wires 21 are installed below the jacquard faucet 2, and a number of wires 21 are connected below the wires 21. The heddle 22, the transmission device includes an input shaft 33, a transmission vertical shaft 34, an output shaft 35 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com